Acrylic solid surface material for artificial marble and preparation method of acrylic solid surface material

A technology of artificial marble and acrylic, applied in the field of artificial stone, can solve the problems of low mechanical properties of plates, achieve the effects of improving mechanical properties, expanding application fields, and increasing bending strength

Inactive Publication Date: 2017-07-28

ZHUHAI SHENGXIYUAN MECHANICAL & ELECTRICAL EQUIP CO LTD

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The mechanical properties of the plate prepared by the above process are low: the impact strength is 3.4KJ / cm2, and the bending strength is 48MPa

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

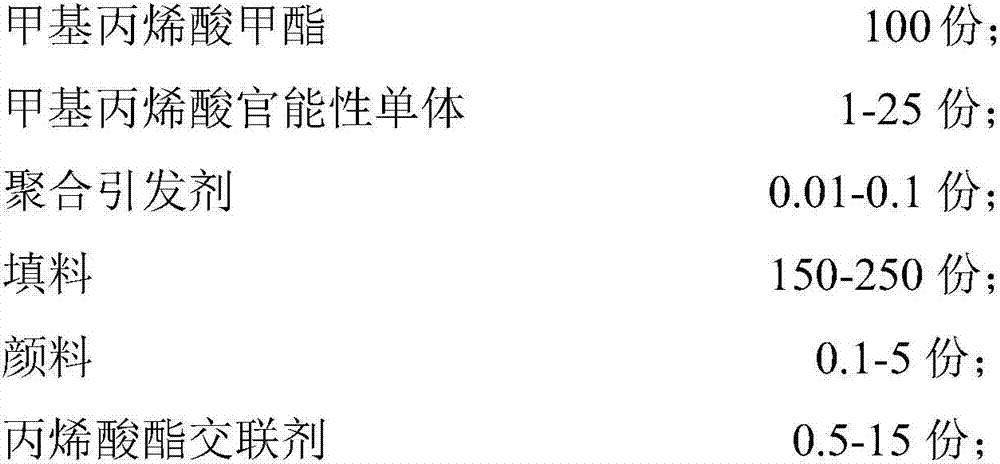

[0029] An acrylic solid surface material of artificial marble, which includes the following raw materials in parts by weight:

[0030]

Embodiment 2

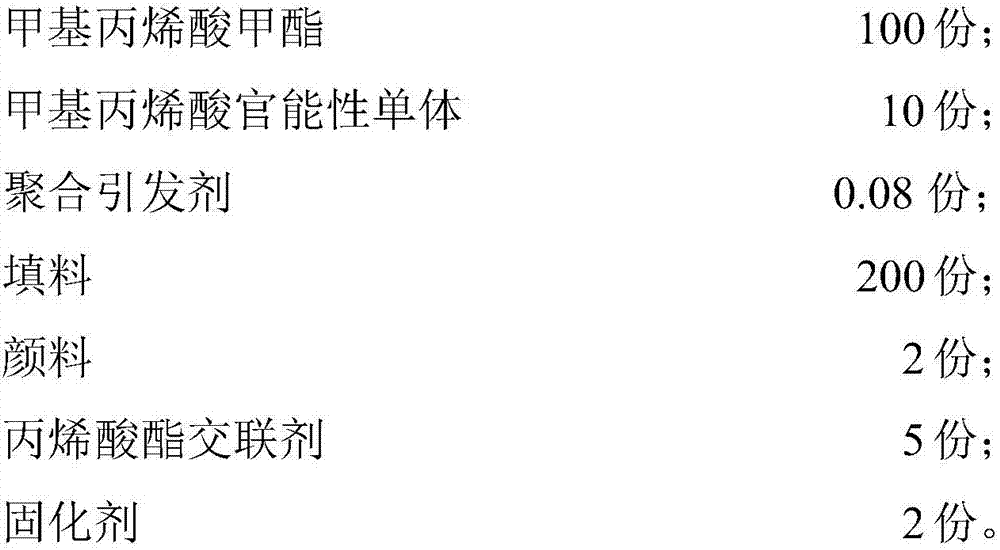

[0032] An acrylic solid surface material of artificial marble, which includes the following raw materials in parts by weight:

[0033]

[0034]

Embodiment 3

[0036] An acrylic solid surface material of artificial marble, which includes the following raw materials in parts by weight:

[0037]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides an acrylic solid surface material for an artificial marble. The acrylic solid surface material is prepared from the following raw materials in parts by weight: 100 parts of methyl methacrylate, 1-25 parts of a methacrylic acid functional monomer, 0.01-0.1 part of a polymerization initiator, 150-250 parts of a filler, 0.1-5 parts of a pigment, 0.5-15 parts of an acrylate cross-linking agent and 0.1-3 parts of a curing agent. The invention further provides a preparation method of the acrylic solid surface material. The methacrylic acid functional monomer is introduced into acrylic solid surface material resin, so that the mechanical property of the acrylic solid surface material is effectively improved, the impact strength is doubled in comparison with that of a traditional technology and can reach about 6.7KJ / cm<2> and the bending strength is also obviously improved and can at least reach 66MPa; the application field of the solid surface material is expanded; and the changing requirements of the market are met.

Description

technical field [0001] The invention relates to the technical field of artificial stone, in particular to an acrylic solid surface material of artificial marble and a preparation method thereof. Background technique [0002] The production of acrylic solid surface artificial marble has a history of more than 20 years. The publicly reported technology is to mix acrylic sheets (MMA) with fillers, add coupling agents and initiators, stir to make a slurry, and then pour it into a mold. 65 The polymerization reaction was carried out at ℃ for 3 hours, and the reaction was continued in an oven at 120℃ for 2 hours to obtain an acrylic solid surface material. [0003] The mechanical properties of the plate prepared by the above process are relatively low: the impact strength is 3.4KJ / cm2, and the bending strength is 48MPa. Contents of the invention [0004] In view of this, the object of the present invention is to provide an acrylic solid surface material of artificial marble, wh...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B26/04C08F220/14C08F220/28C08F222/14

CPCC04B26/04C04B2201/50C08F220/14C04B14/305C04B14/36C04B24/045C08F220/281C08F222/102

Inventor 王勇刚杨代明

Owner ZHUHAI SHENGXIYUAN MECHANICAL & ELECTRICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com