Heat-resistant impact-resistant low-floating-fiber short-fiber reinforced PBT/ABS alloy material for electrical equipment shell, and preparation method thereof

A technology for electrical shells and alloy materials, which is applied in the field of heat-resistant, impact-resistant, low-floating short fiber reinforced PBT/ABS alloy materials and its preparation, which can solve the problems of low impact strength and low thermal deformation temperature, and achieve low molding shrinkage , high dimensional stability and high heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

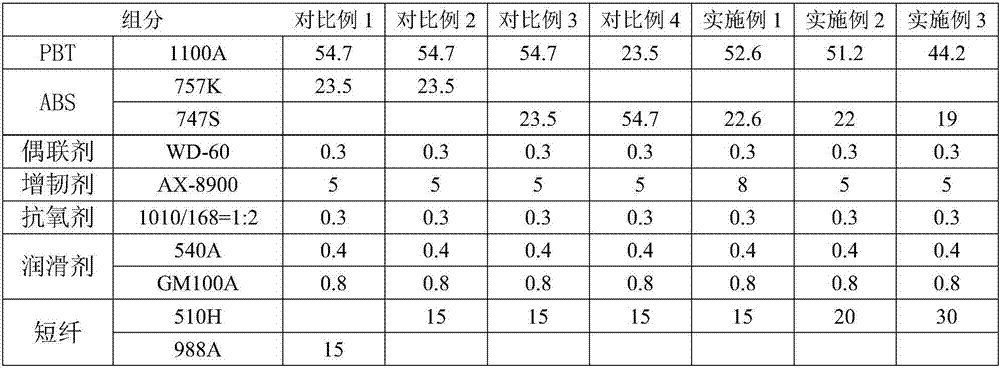

Examples

Embodiment 1~3

[0033] Embodiment 1~3, its preparation method comprises the steps:

[0034] First add the weighed polybutylene terephthalate (1100A), acrylonitrile-butadiene-styrene copolymer (747S) and silane coupling agent (WD-60) to the high-speed mixer according to Table 1 , mix for 1-2 minutes, and then weigh toughener (AX-8900), antioxidant (1010 / 168=1:2), diffusing agent (540A), silicone powder (GM100A) and short fiber ( 510H) added to the above mixed materials and mixed for 1-2 minutes. Finally, the mixed materials are added to the hopper of a twin-screw extruder to be melted and extruded. The temperature of each section of the twin-screw extruder is: the temperature of zone 1 is 60°C; the temperature of zone 2 is 245°C; the temperature of zone 3 is 240°C; the temperature of zone 4 is 220°C; the temperature of zone 5 is 235°C; ℃. The screw speed of the twin-screw extruder was 38 rpm / min. The products produced in Examples 1-3 are respectively denoted as B1-B3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap