Composite damping rubber vibration reducing bearing

A composite damping and rubber damping technology, applied in bridge parts, bridges, buildings, etc., can solve problems such as insufficient damping performance, and achieve the effects of wide applicability, prolonging structural period and improving damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

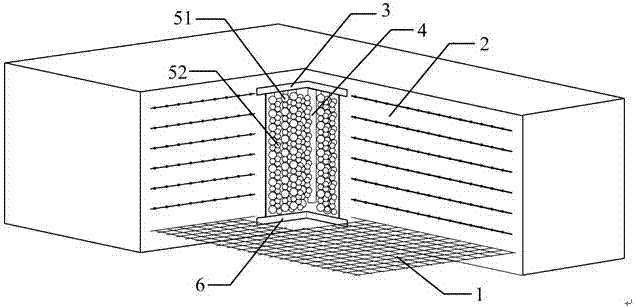

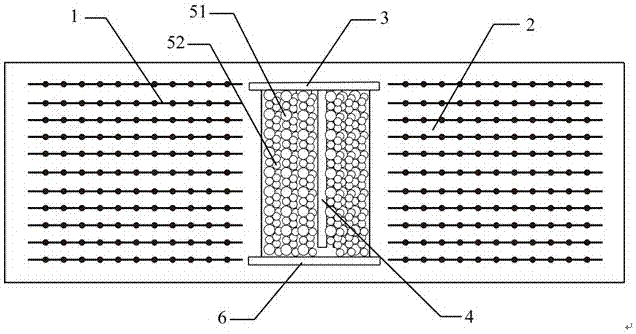

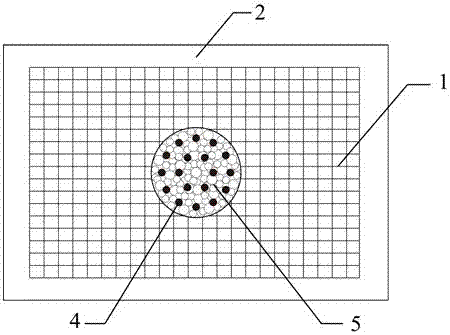

[0032] Example 1: see figure 1 , figure 2 and image 3 , a composite damping rubber shock-absorbing bearing, which is composed of high-strength fine-density steel wire mesh 1, high-damping rubber layer 2, upper sealing plate 3, thin soft steel rod 4, multi-graded mixed filler material 5 and lower sealing plate 6; The multi-graded mixed filler 5 is composed of fine particle damping material 51 and fine rubber elastic ball 52 in a mixing ratio. Among them, the high-strength fine steel wire mesh 1 and the high-damping rubber layer 2 reserve holes, so that the multi-graded mixed filler 5 can be filled into the high-damping rubber layer 2; the upper end of the thin and soft steel rod 4 is fixed on the upper sealing plate 3, and the thin and soft steel 4. The main body is embedded in the multi-graded mixed filler 5.

[0033] As one of the technical points of the present invention, the strong fine-grained steel wire mesh 1 and the high damping rubber layer 2 are fully bonded and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com