Construction method and installation precision control method of steel lattice column in main engine room of ship lift

A technology of a steel lattice column and a construction method, which is applied in the vertical lifting of ship machinery, boat lifting devices, construction and other directions, can solve the problem that it is difficult to control the installation accuracy and quality of anchor bolts, displacement and deformation of embedded parts of column feet, and steel lattice columns. There are many problems such as a large number of problems, so as to achieve the effect that the production accuracy is easy to ensure, the installation height is large, and the installation accuracy requirements are high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the drawings.

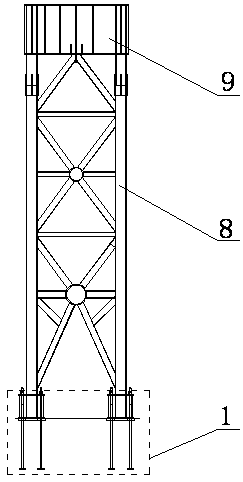

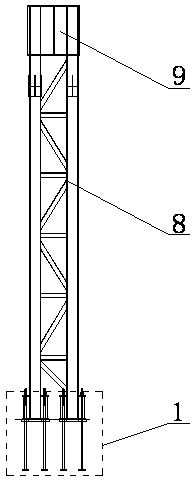

[0039] Such as figure 1 with 2 As shown, the upper structure of a group of steel lattice columns includes a four-tube column body 8 and a shoulder beam 9. The four-tube column body 8 includes four tubular columns, and the four tubular columns are welded and fixed to each other and the top ends are connected. The line forms a rectangle. The shoulder beam 9 includes an upper cover plate, a lower cover plate and a web. The shoulder beam 9 is welded to the top of the four-tube column body 8; the steel lattice column is made to be divided into column welding, shoulder beam welding and four-tube The column body and the shoulder beam are erected on multiple working surfaces, and the streamlining operation in the factory can greatly improve the production efficiency and shorten the construction period. The environment in the factory is flat and fully equipped, and the production accuracy is ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com