Variable-rail insulation door

A technology for thermal insulation doors and tracks, which is applied in windows/doors, fire doors, door/window accessories, etc. It can solve the problems of reducing the space occupied by the door storage, failing to meet the use requirements, and poor overall sealing performance, so as to achieve overall sealing performance Good, beneficial to light weight, reducing the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

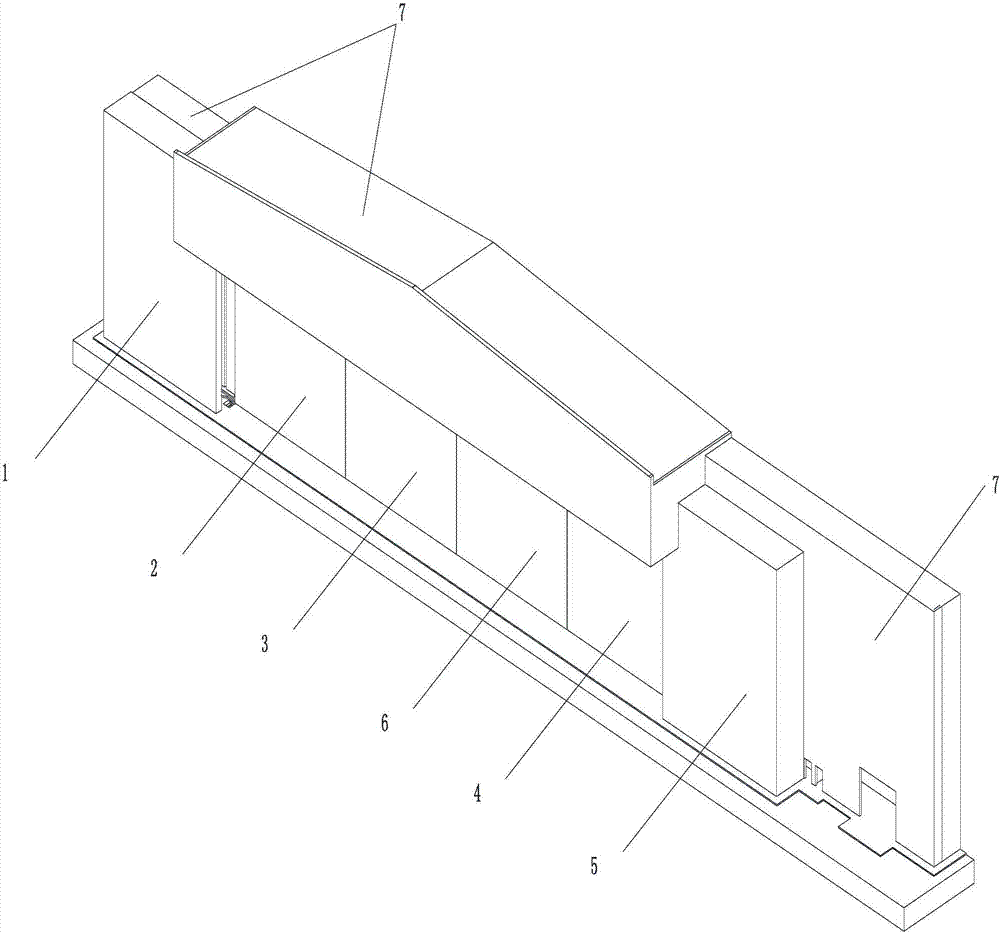

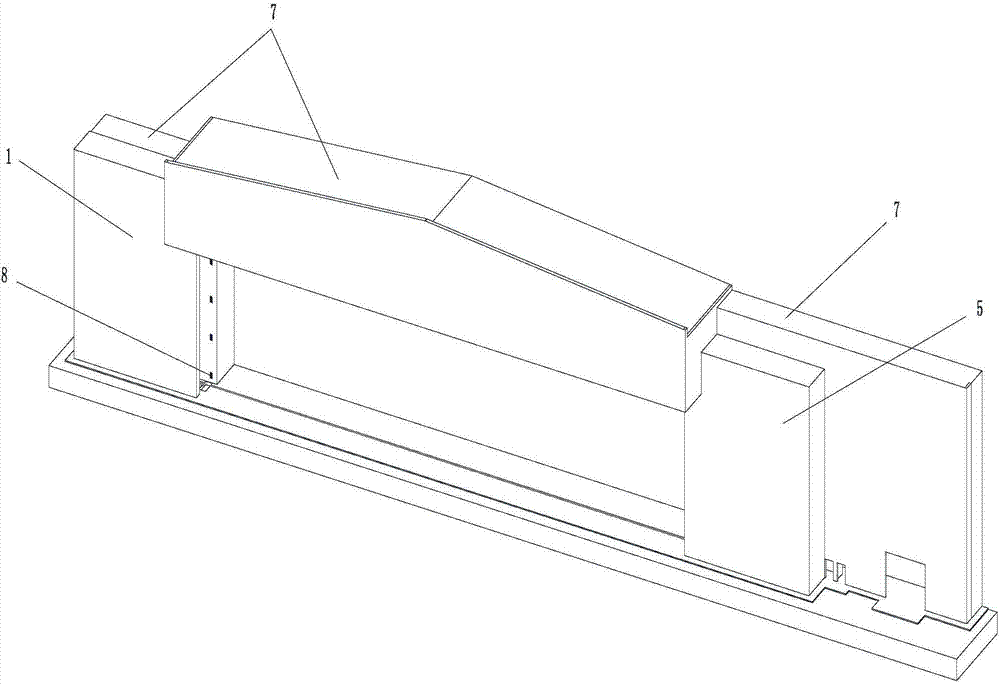

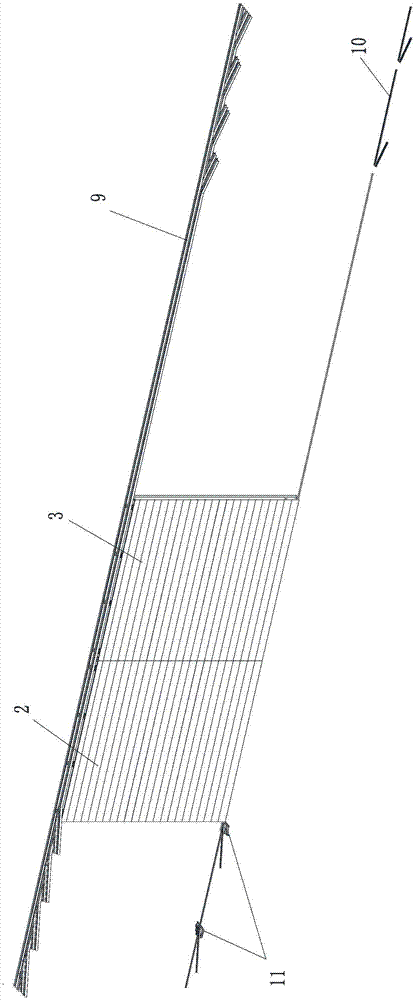

[0045] like Figure 1 to Figure 14 As shown, a track-changing heat preservation door includes an upper track 9, a lower track 10 and a door body 50; an upper guide wheel 12 is arranged on the top of the door body 50, and a running mechanism 28 is arranged at the bottom thereof, and the running mechanism 28 is made of steerable traveling wheel and the drive motor that links to each other with it; Described upper guide wheel 12 is arranged in the upper track 9, and steerable traveling wheel is arranged in the lower track 10.

[0046] Described upper track 9 comprises upper straight track 29, is respectively provided with several upper inclined tracks 30 at the two ends of upper straight track 29, and the quantity of each end upper inclined track 30 is identical with the quantity of the last guide wheel 12 of a door body; On the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com