High tension electroscope

An electroscope, high-voltage technology, applied in the direction of instruments, measuring electrical variables, measuring current/voltage, etc., can solve the problems of increasing malignant misoperations and personal electric shock casualties, unable to guarantee lines, personal electric shock casualties, etc., to reduce personal electric shock casualties. The effect of reducing the risk of falling objects hurting people and avoiding malignant misuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

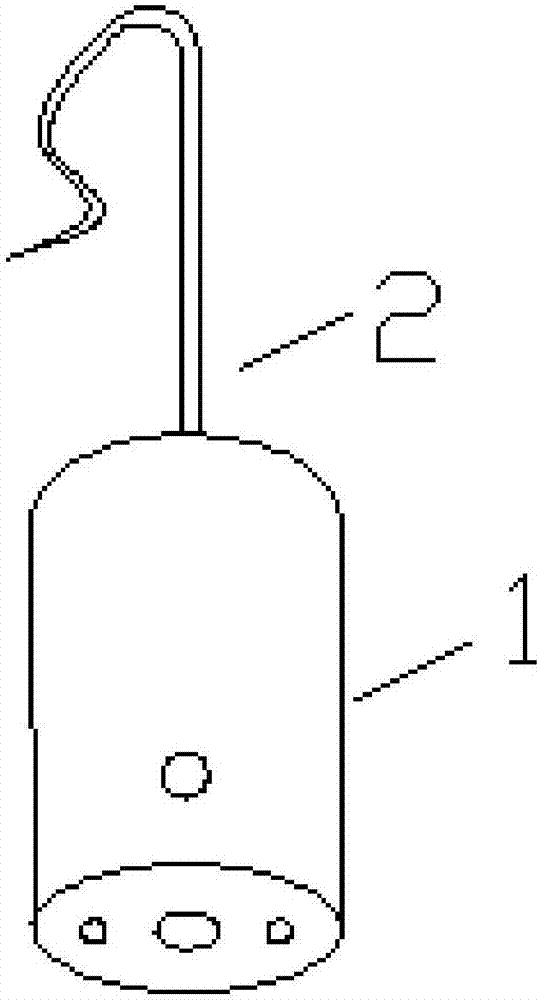

[0022] Such as figure 1 As shown, a high-voltage electroscope includes an electroscope 1 and a contact electrode 2. One end of the contact electrode 2 is fixed on the electroscope 1, and the other end of the contact electrode 2 is provided with a lifting mechanism. The high-voltage electroscope passes through The detachment mechanism is hung on the conductor under test to realize the passage from the conductor under test to the electroscope 1 .

[0023] The detachment mechanism is a hook structure, preferably, the detachment mechanism is an S-shaped hook structure; the detachment mechanism and the contact electrode 2 are integrally formed, and both are elastic metal structures that are not easily deformed plastically.

[0024] Wire grooves are arranged in the lifting mechanism, and the layout of the wire grooves on the lifting mechanism is narrow near the two ends of the lifting mechanism and wide at the middle part of the lifting mechanism.

[0025] When the high-voltage ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com