Dense bus duct socket device

A busway, intensive technology, applied in the direction of fully enclosed busbar devices, coupling devices, connecting device components, etc., can solve the problems of burning equipment, increasing temperature rise, low overload capacity, etc., to ensure assembly accuracy and speed, Ensure the level of protection and the effect of strong versatility

Inactive Publication Date: 2017-07-28

鼎圣集团有限公司

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Due to the structure of the existing bus duct socket, the copper pins are not directly inserted outside the copper pins corresponding to the phase sequence during the plugging process of the bus main line current and the plug box, so the contact resistance is large and the overload capacity is low. Copper and aluminum materials are directly over-plated, which increases the temperature rise

Due to the different hardness of copper and aluminum materials, the number of times of plugging and unplugging between the two cannot meet the standards and use requirements. Because the temperature rise of the pins exceeds the standard, it will cause a short circuit, and in severe cases, it will even cause a failure to burn the device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0024] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

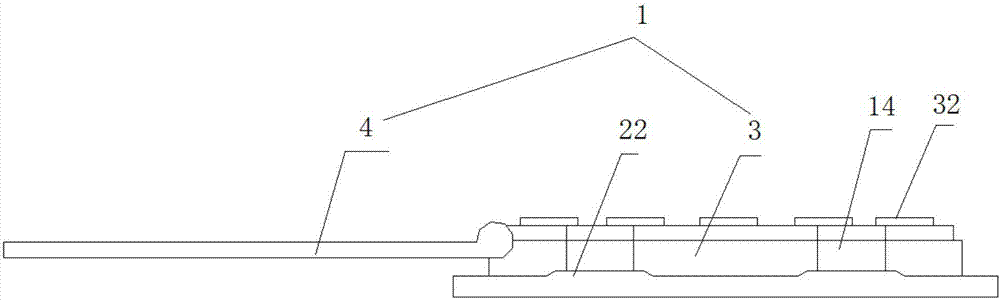

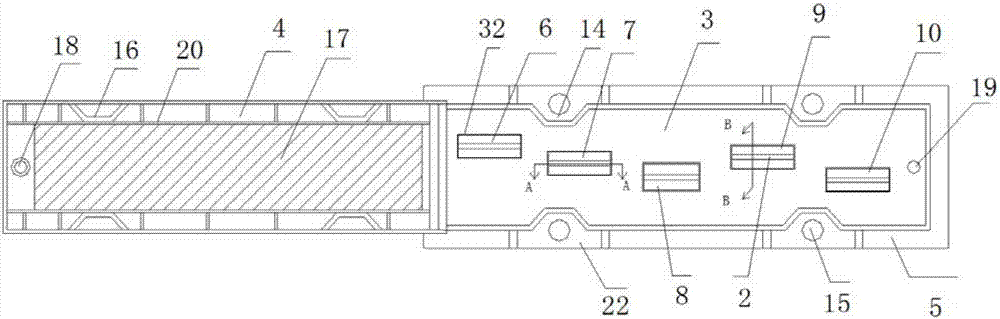

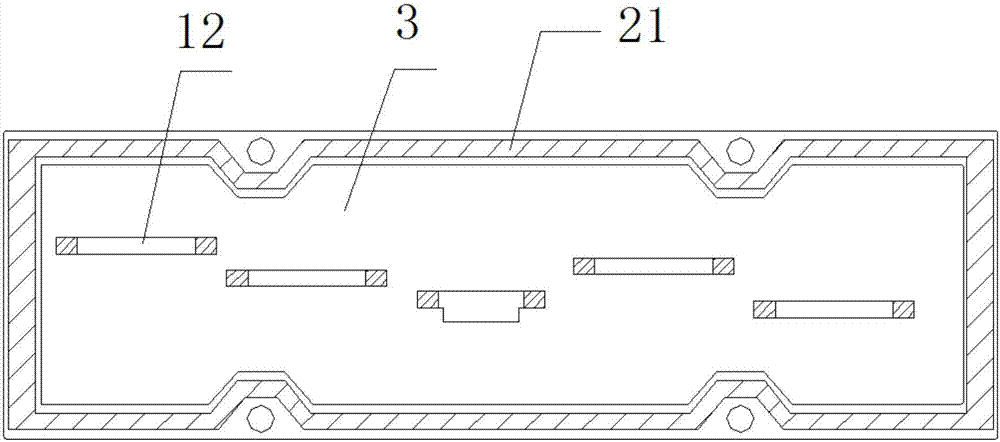

The invention relates to a dense busway socket device, which includes a socket mechanism and a pile head. The socket mechanism includes a socket seat and a socket cover. The socket seat is a cuboid structure, and a ring of fixed support seats is provided on the outer periphery of the bottom of the socket seat. The first socket, the second socket, the third socket, the fourth socket and the fifth socket are arranged alternately on the socket seat. The pile head includes a plug-in end and a fixed end, and the pile head is inserted into the first socket. , The second socket, the third socket, the fourth socket and the fifth socket have achieved high density, and have the characteristics of low impedance, fast heat dissipation, and simple process.

Description

technical field [0001] The invention relates to a socket device, in particular to a dense busway socket device. Background technique [0002] Due to the structure of the existing bus duct socket, the copper pins are not directly inserted outside the copper pins corresponding to the phase sequence during the plugging process of the bus main line current and the plug box, so the contact resistance is large and the overload capacity is low. Copper and aluminum materials are directly over-plated, which increases the temperature rise. Due to the different hardness of copper and aluminum materials, the number of times of plugging and unplugging between the two cannot meet the standards and use requirements. Because the temperature rise of the pins exceeds the standard, it will cause a short circuit, and in severe cases, it will even cause a failure to burn the device. Contents of the invention [0003] Aiming at the above problems, the present invention proposes a dense bus du...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02G5/08H01R13/629H01R13/04H01R13/52

CPCH02G5/08H01R13/04H01R13/5202H01R13/629

Inventor 李立军张开银

Owner 鼎圣集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com