Standard hole machining device for bathtub

A processing device and standard hole technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as poor quality, difficulty in ensuring the position and size of holes, and non-standard drilled holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

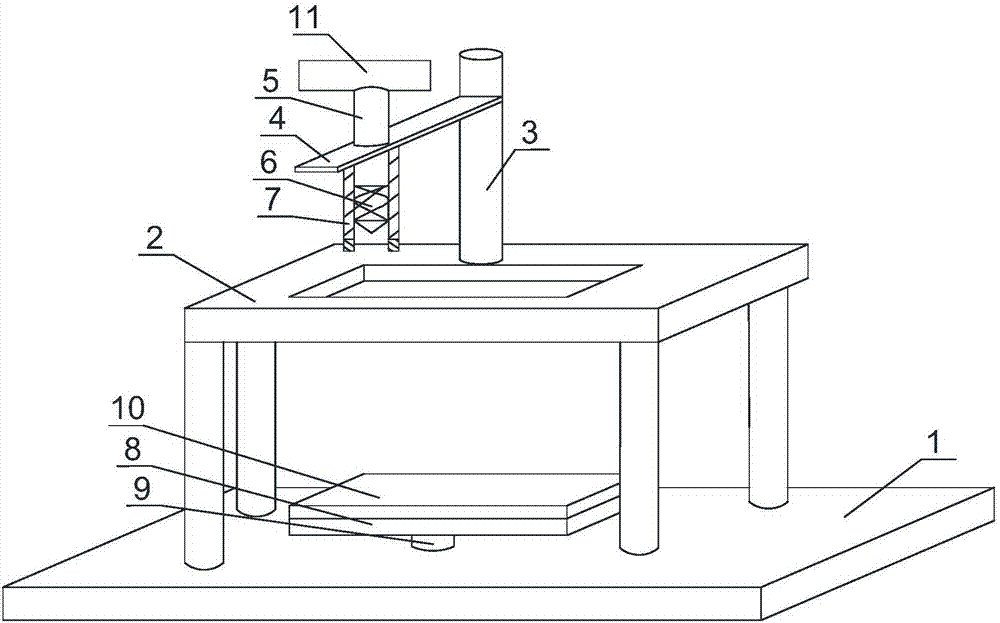

[0022] Such as figure 1 As shown, the standard hole processing device for bathtubs of the present invention includes a base 1, a workbench 2 is connected above the base 1, and a through groove 3 for placing workpieces is arranged on the workbench 2, and one side of the through groove 3 A drilling tool and a fixing frame for fixing the drilling tool are arranged on the workbench 2 of the working table, and the fixing frame includes a telescopic column 3 vertically installed on the workbench 2, and the top of the telescopic column 3 is connected with a telescopic rod 4, and the telescopic rod 4 Horizontally installed, the end of the telescopic rod 4 away from the telescopic column 3 is provided with a through hole for the insertion of the drilling tool. Twist drill bit 6 is arranged, and the bottom of expansion rod 4 is provided with sleeve pipe 7 with buffer pad, and described sleeve pipe 7 is sleeved outside drill pipe 5 and is tangent to drill pipe 5 . A swivel for the teles...

Embodiment 2

[0025] Based on Embodiment 1, the base 1 below the through groove 3 is provided with a placement platform 8 for placing workpieces, the placement platform 8 is connected to the base 1 through a hydraulic column 9, and when the placement platform 8 is connected to the through groove 3, the placement platform 8 is inscribed with through groove 3. The upper surface of the placing table 8 is covered with a rubber pad 10 .

[0026] The placing table is used to place the bathtub, which plays a role of fixing and strengthening the bathtub; when it is not working, the placing table is at the bottom of the base, which is convenient for placing the bathtub. After the bathtub is placed, the placing table can be raised by the hydraulic column, and the placing table rises to It can be stopped inside the through groove; on the one hand, the rubber pad can fix the bathtub to prevent the bathtub from sliding on the placing table and affect the quality of drilling, on the other hand, it can ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com