Spring reciprocating cutting device

A technology of cutting device and spring device, which is applied in the direction of metal processing, etc., can solve the problems of long cleaning auxiliary time, difficult cleaning and disinfection, impossible use, etc., and achieve the effect of uniform force, convenient sanitation and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

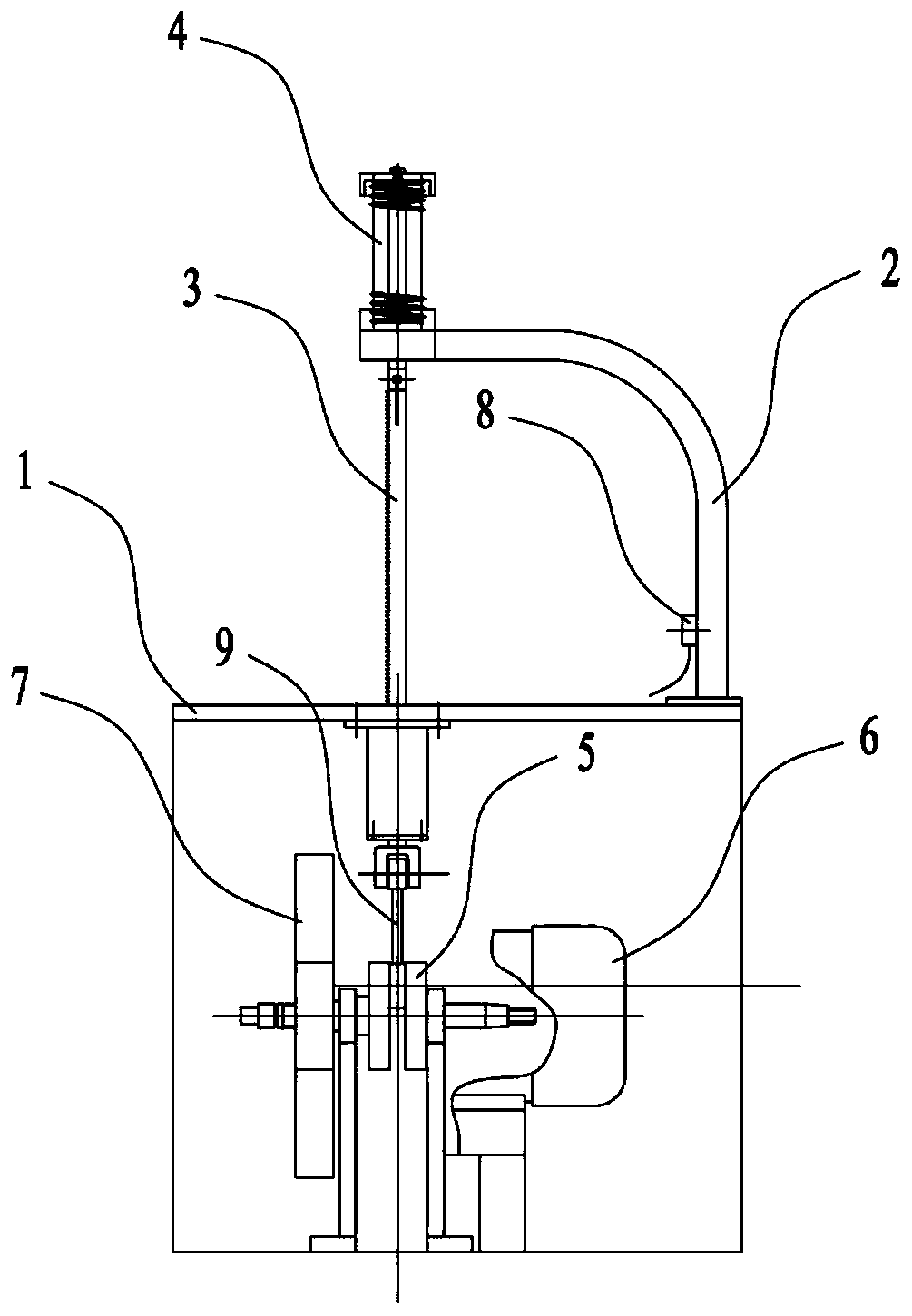

[0029] refer to figure 1 Shown, one embodiment of the present invention is a kind of spring-type reciprocating cutting device, comprises frame 1, needs to install support 2 on the top of frame 1, and needs to install a vertical saw blade 3 on the support 2 movably, this The upper end of saw blade 3 needs to be connected with spring device 4 power, and this spring device 4 also needs to be installed on the frame 1, is used for applying upward pulling force to saw blade when spring device is stretched, to strengthen described The tension of the saw blade as it moves up and down. In addition, the lower end of the aforementioned vertically installed saw blade 3 is also power-connected with the eccentric wheel 5 , and the eccentric wheel 5 is power-connected with the output end of the motor 6 . as figure 1 Shown, the structure of support 2 can be set to L type, promptly one end is installed on the frame 1, and the other end is suspended in the air as free end, and aforementioned ...

Embodiment 2

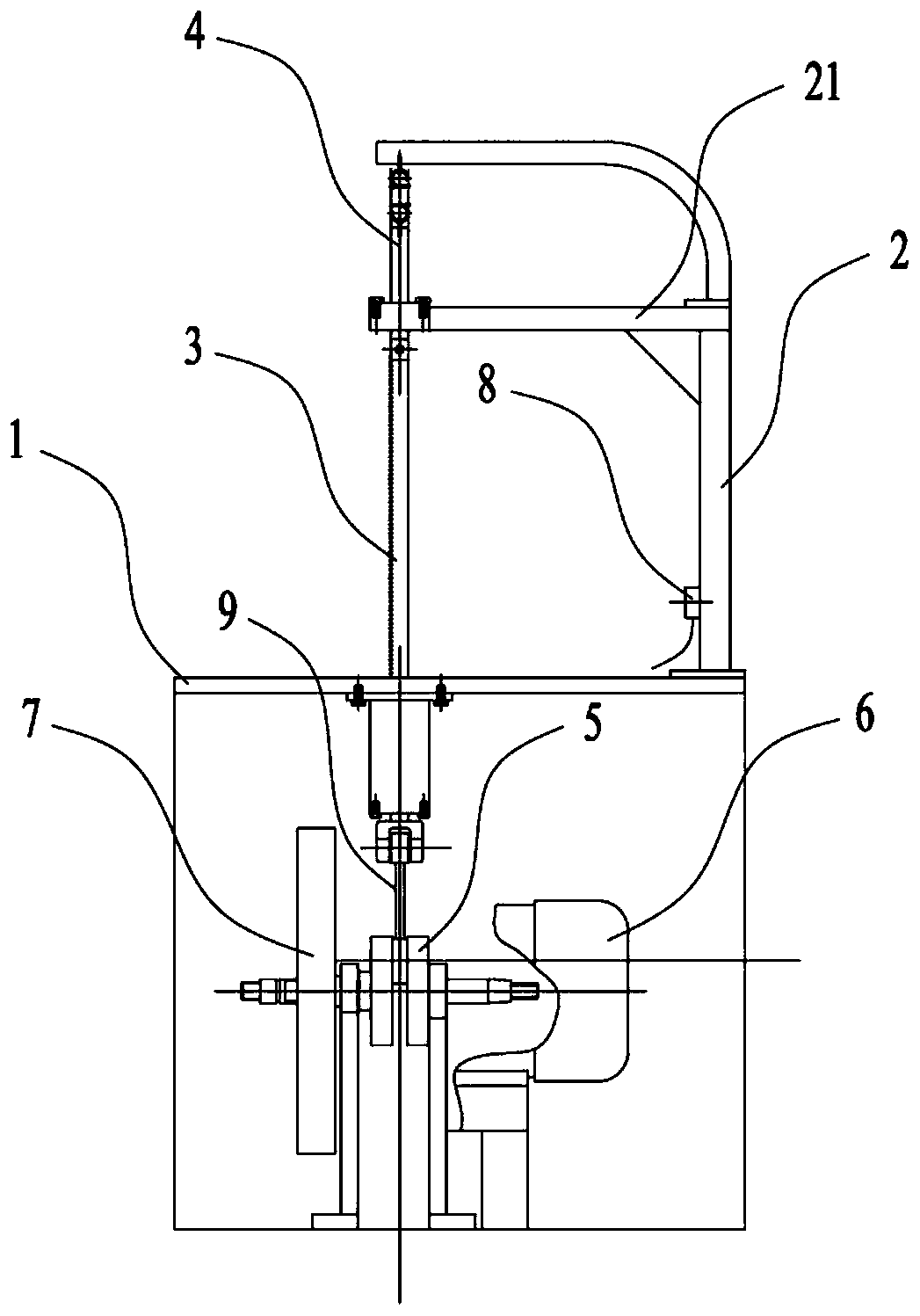

[0036] refer to figure 2 As shown, in another embodiment of the present invention, another implementation of the spring device is disclosed, and the structure of the above-mentioned bracket 2 is improved, specifically, the bracket 2 is still set in an L shape, and then the bracket The middle part of 2 adds a transverse first connecting frame 21, and this first connecting frame 21 is fixedly installed on the support 2, and the above-mentioned spring device 4 is installed between the free end of the support 2 and the first connecting frame 21, and then the The first connecting frame 21 is also set on the outside of the upper end of the saw blade 3, and the material is placed on the upper part of the frame 1. When it is close to the sensor 8, the sensor 8 is triggered, and then the control module controls the deceleration motor to start running and decelerate. The output end of the motor drives the pulley 7 to rotate through the belt, and then the pulley 7 drives the eccentric w...

Embodiment 3

[0038] refer to image 3 As shown, in another embodiment of the present invention, this embodiment discloses another implementation of the spring device, and another structural improvement is made to the above-mentioned bracket 2, specifically as image 3As shown, the above-mentioned bracket 2 is set as a split first support frame 22 and a second support frame 23, and a horizontal second connecting frame 24 is installed on the first supporting frame 22, and the second connecting frame 24 is set on the saw The outside of the upper end of the knife 3, then the above-mentioned spring device 4 is installed on the upper end of the second support frame 23, and finally the upper end of the saw blade 3 is dynamically connected with the spring device 4 through the third connecting frame 25. In addition, the third connecting frame 25 The vicinity of the middle part also needs to be movably installed on the first support frame 22; by installing the spring device 4 on the second support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com