Vehicle body structure for a two-track vehicle

A body and vehicle technology, applied in the substructure, vehicle components, vehicle design optimization, etc., can solve the problem of high risk of damage to the rear axle module and supports, and achieve the effect of simplifying the connection geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

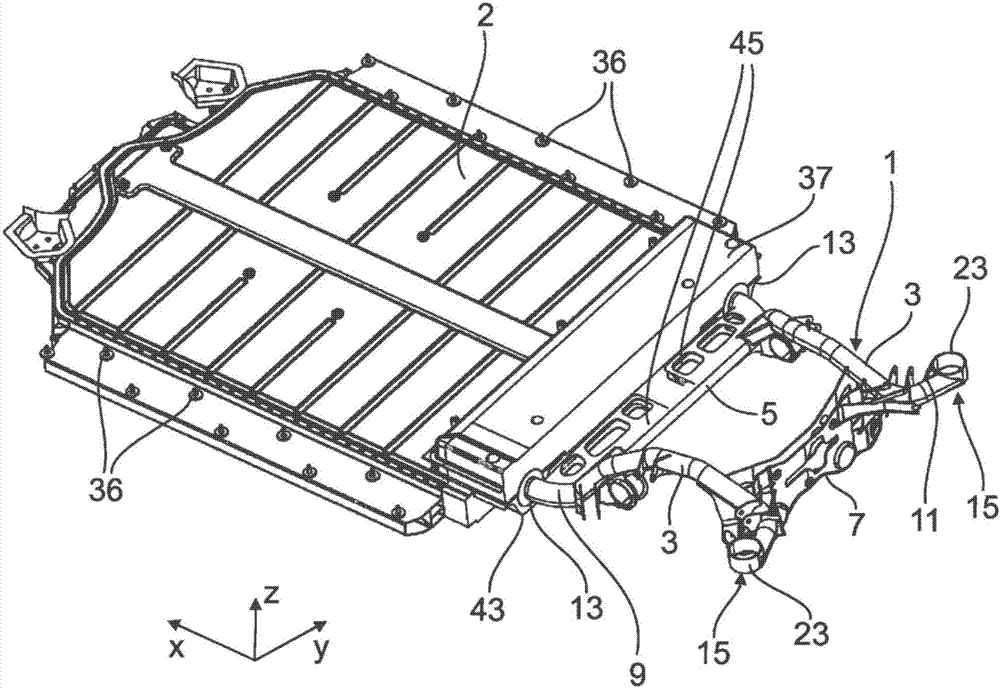

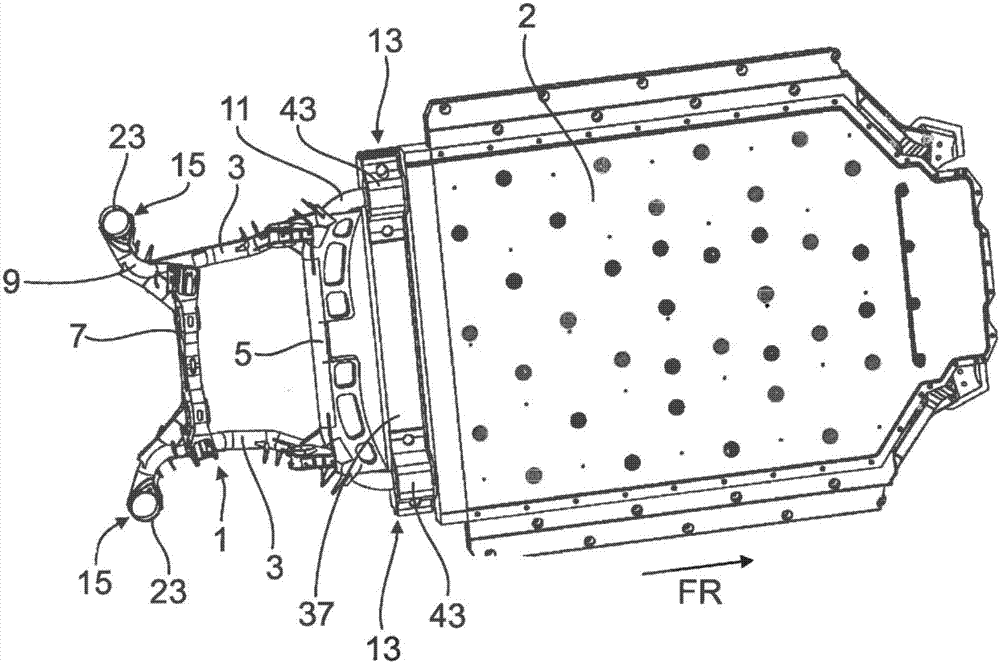

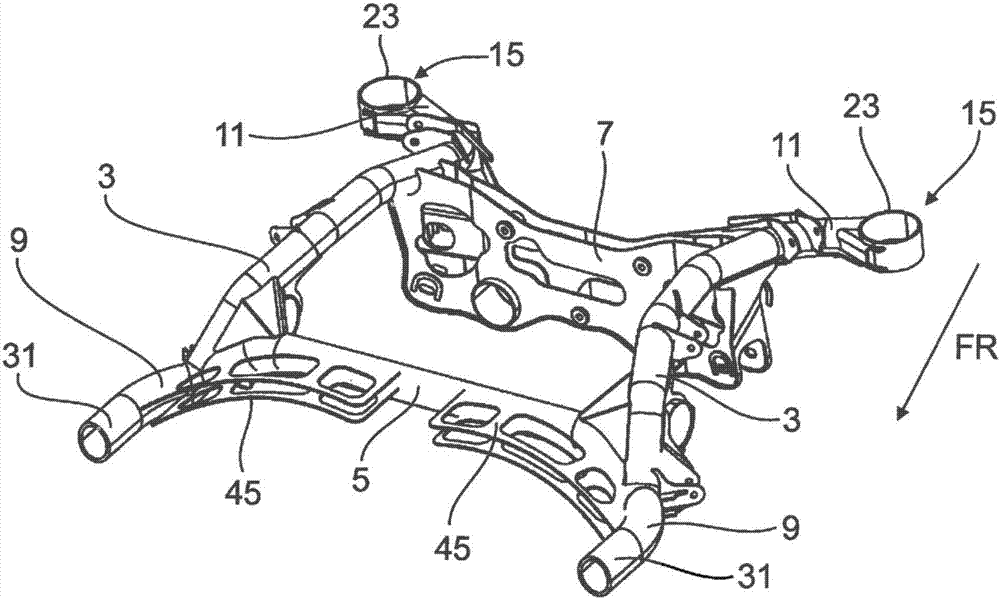

[0029] exist figure 1 shows in a perspective view the arrangement of a rear subframe 1 for the rear axle of the vehicle and a traction battery 2 at the front in the vehicle longitudinal direction x, which can be installed in an electrically driven motor vehicle. The subframe 1 is in figure 1 The center is configured as a rectangular closed structure and has subframe longitudinal supports 3 spaced apart from one another in the vehicle transverse direction y as well as a front transverse support 5 and a rear transverse support 7 . The two transverse supports run in the transverse vehicle direction y and connect the two subframe longitudinal supports 3 to one another at the front and rear corner points. The two subframe longitudinal bearings 3 extend forward and rearward along the vehicle longitudinal direction x correspondingly beyond the corner joints to form a longitudinal bearing front section 9 and a longitudinal bearing rear section 11 ( image 3 ).

[0030] The subframe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com