Multifunctional end effector

An end-effector and multi-functional technology, which is applied in aircraft assembly and other directions, can solve problems such as uneven screw quality, limited working space, and poor working conditions, and achieve efficient and precise work, small overall size, and clear overall structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

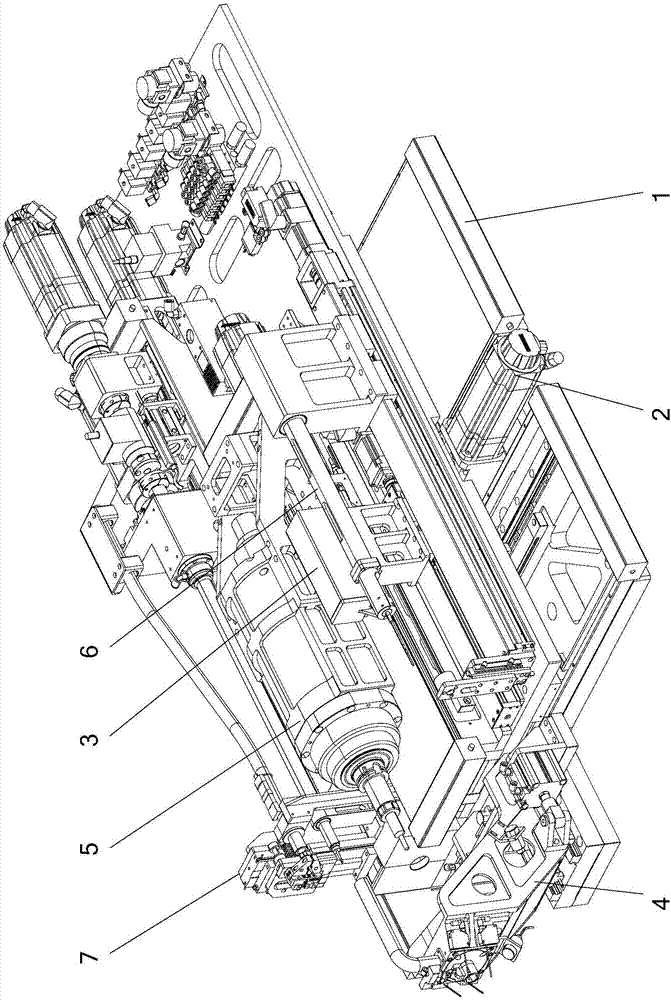

[0045] see figure 1 , The multifunctional end effector of the present invention includes a base 1 , a translation unit 2 , a photogrammetry unit 3 , a presser foot unit 4 , a hole making unit 5 , an aperture measuring unit 6 and a nail tightening unit 7 .

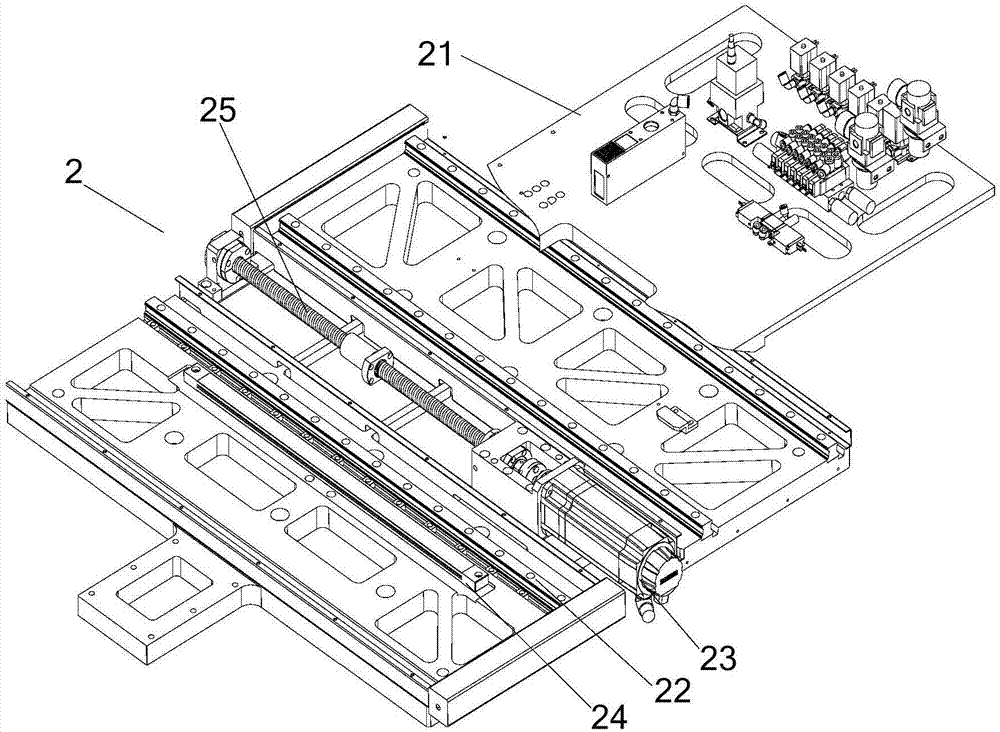

[0046] see figure 2 The translation unit 2 includes a traversing slide table 21 and a first actuator 23 that drives the traversing slide table 21 to slide along the transverse guide rail 22, and a first grating ruler 24 arranged laterally on one side of the transverse guide rail 22, the first The grating ruler 24 is used to detect the displacement of the traverse slide table 21 . In this embodiment, the first actuator 23 is a servo motor fixed on the base 1 , and the transmission connection between the servo motor and the traversing slide 21 is realized through a screw rod 25 .

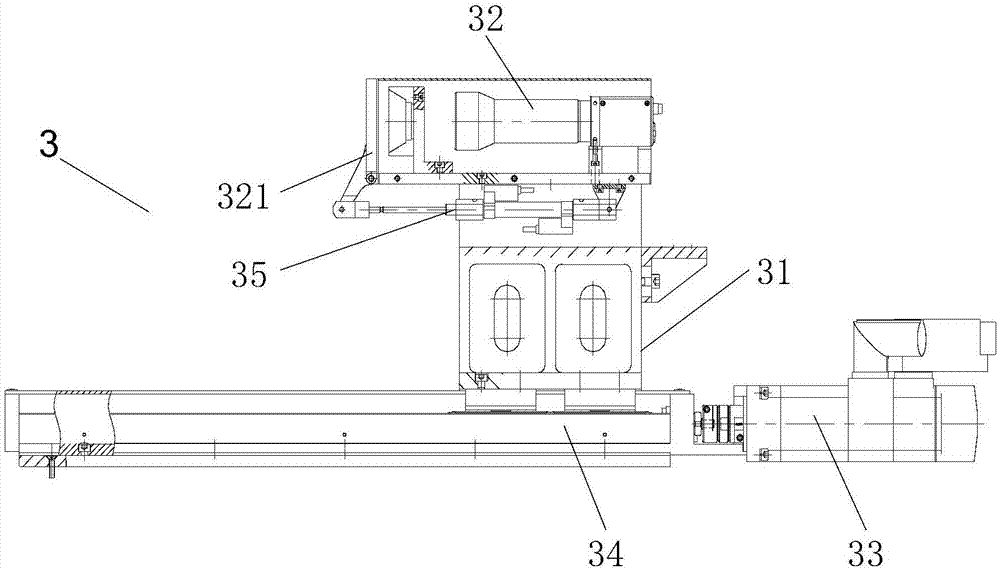

[0047] see image 3 , the photogrammetry unit 3 comprises a camera support 31, a camera 32 mounted on the camera support 31 and a servo motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com