Confluence mechanism

A technology of convex rails and rollers, which is applied to conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as hanger jamming, high error rate, and hanger drop, so as to improve processing efficiency, reduce processing difficulty, and have a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

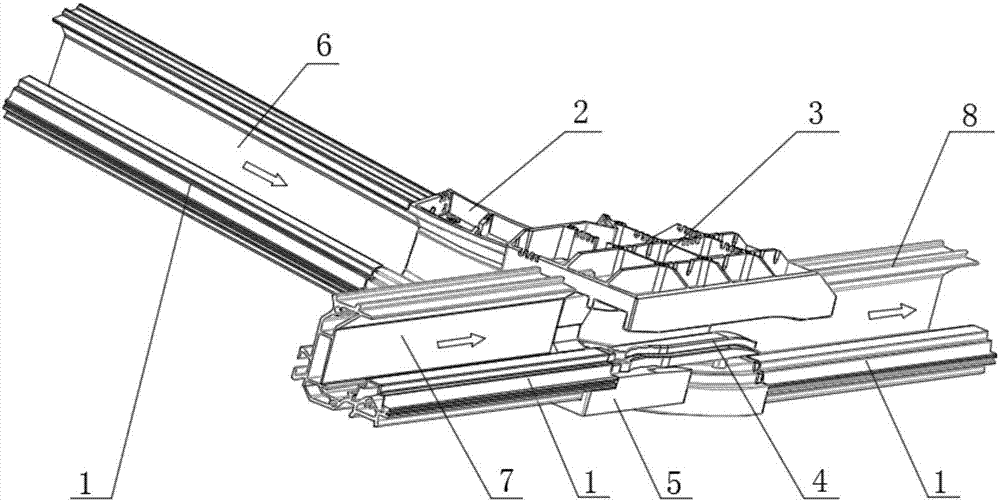

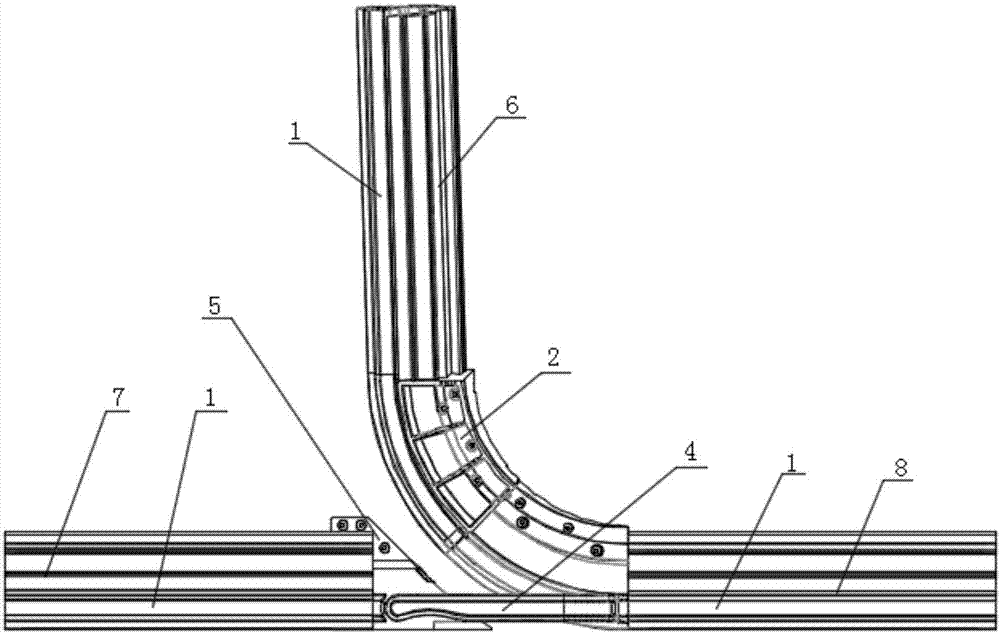

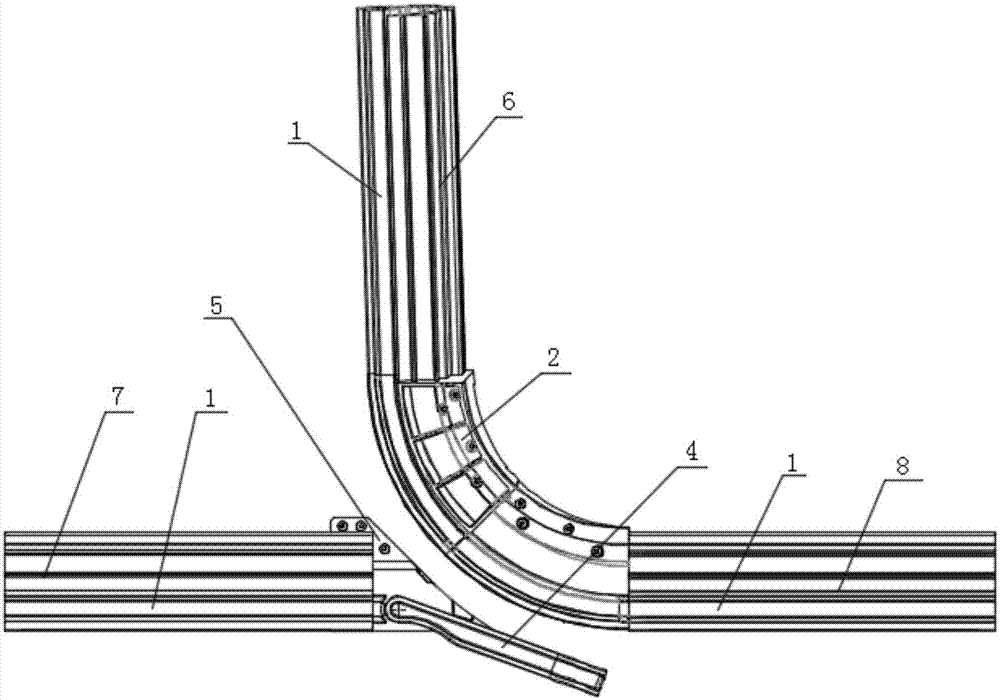

[0019] Such as Figure 1-6 As shown, the merging mechanism provided by the present invention includes a first branch rail 6 , a second branch rail 7 , and a merging rail 8 . The outlet end of the first branch rail 6 is connected with the inlet end of the confluence rail 8 , and the outlet end of the first branch rail 6 can also be connected with the inlet end of the confluence rail 8 through the elbow seat 2 . The second branch rail 7 and the confluence rail 8 are on the same straight line, and there is a gap between the second branch rail 7 and the confluence rail 8 . The bottoms of the first branch rail 6, the second branch rail 7, the confluence rail 8 and the elbow seat 2 are all provided with a roller hanger ledge 1, and the roller clothes hanger can roll on the roller hanger ledge 1. The first branch rail 6, the elbow seat 2, and the roller clothes hanger protruding rail 1 on the converging rail 8 are connected end to end successively to form a continuous protruding rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com