Inner cooling circulation system structure for magnetic pump

A technology of circulation system and magnetic pump, which is applied to components, pumps, and pump components of elastic fluid pumping devices, and can solve problems such as heat removal, loss of magnetism of the internal magnetic rotor, and reduction of natural circulation capacity, etc., to achieve Improve anti-cavitation performance, improve flow capacity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

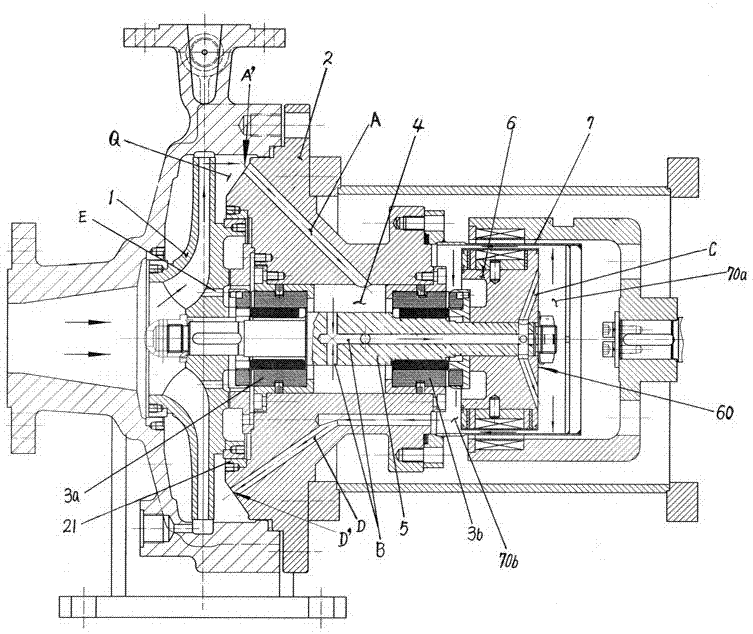

[0018] The structure of the internal cooling circulation system of the magnetic pump of the present invention is formed on the pump cover 2 by the high-pressure zone at the outlet of the impeller 1 corresponding to the pump cavity Q, and the liquid inlet hole A leading to the shaft cavity 4 between the left and right sliding bearings 3a, 3b, The liquid inlet hole B leading to the rear end of the main shaft 5 is opened on the main shaft 5 in the shaft cavity 4 between the left and right sliding bearings 3a, 3b, and the liquid inlet on the main shaft 5 is distributed radially on the rear end surface 60 of the inner magnetic rotor 6. The rear end of the hole B corresponds to the connected liquid inlet hole C, and the inclined radial liquid inlet hole C on the inner magnetic rotor (6) forms a centrifugal pump effect on the medium liquid, and the opening on the pump cover 2 corresponds to the outer side of the pump cover seal ring 21 The liquid outlet hole D leading to the inner cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com