Pipeline sedimentation automatic control support for urban comprehensive pipe gallery

A technology for comprehensive pipe gallery and pipeline settlement, applied in the direction of pipe supports, pipes/pipe joints/pipes, artificial islands, etc., can solve the problems of long-distance pipe manual correction, large error, unsuitable for popularization and low degree of automation, etc. Save labor costs, reduce security risks, and respond quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

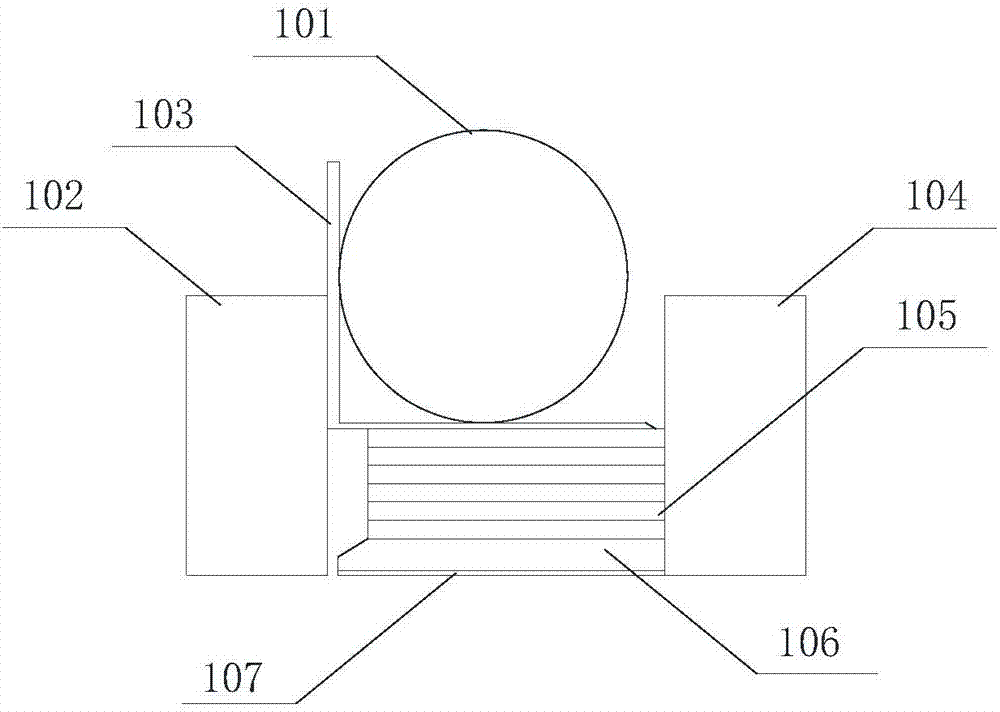

[0027] The automatic control support for pipeline settlement in this embodiment includes a hoist 102, a hoist bracket 103, a steel plate placement device 104, a pressure-bearing steel plate 105, a pressure-bearing foundation 106 and a pressure sensor 107 installed at the bottom of the pressure-bearing foundation.

[0028] The pipeline 101 is carried on the hoist bracket 103, and the hoist bracket 103 has a pressure-bearing steel plate 105 and a pressure-bearing foundation 106 respectively for supporting the weight of the pipeline 101 and the hoist bracket 103.

[0029] A pressure sensor 107 is installed at the bottom of the pressure-bearing foundation 106 for monitoring the pressure carried by the pressure-bearing foundation 106 . Pressure sensor 107 may indirectly monitor the bottom pressure of pipeline 101 .

[0030] When the pressure sensor 107 at the bottom of the pressure-bearing foundation 106 detects that the pressure value is lower than the normal value, the hoist 102 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com