Biomass pyrolysis gasification furnace of star composite structure

A combined structure, pyrolysis and gasification technology, applied in the direction of incinerators, coke ovens, combustion types, etc., can solve the problems of difficult to reach the pyrolysis temperature, complex furnace structure, large overall size, etc., to achieve sufficient pyrolysis, improve Pyrolysis efficiency, small overall size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

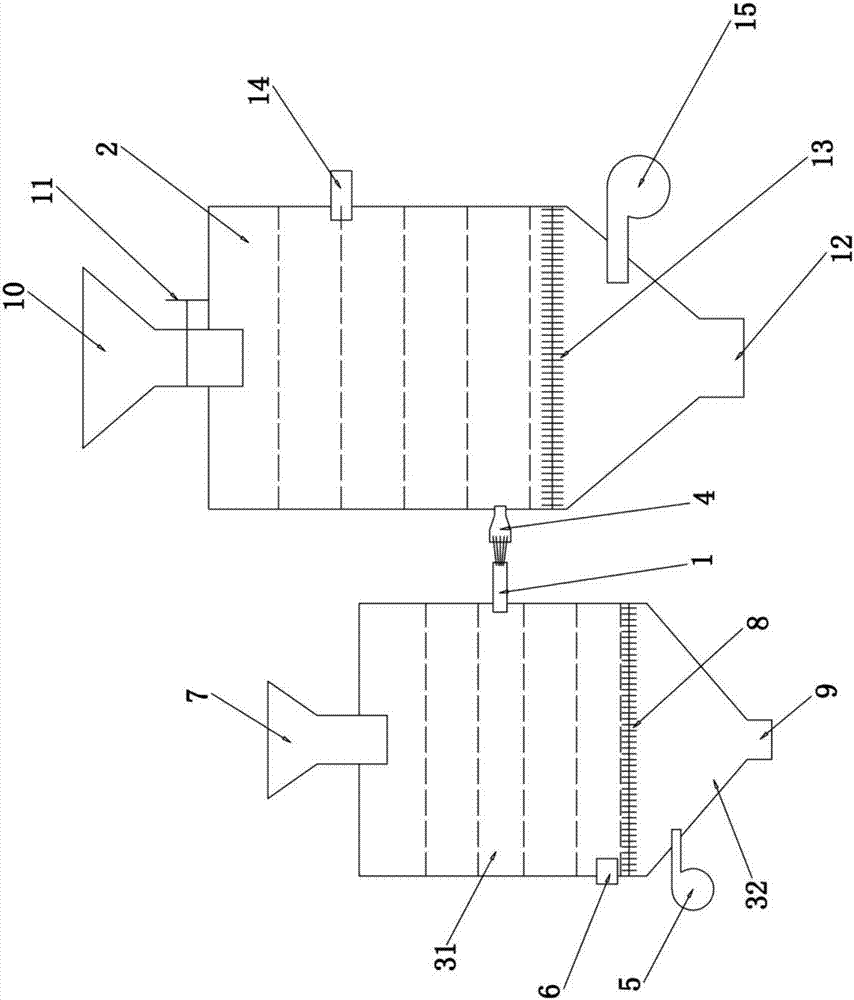

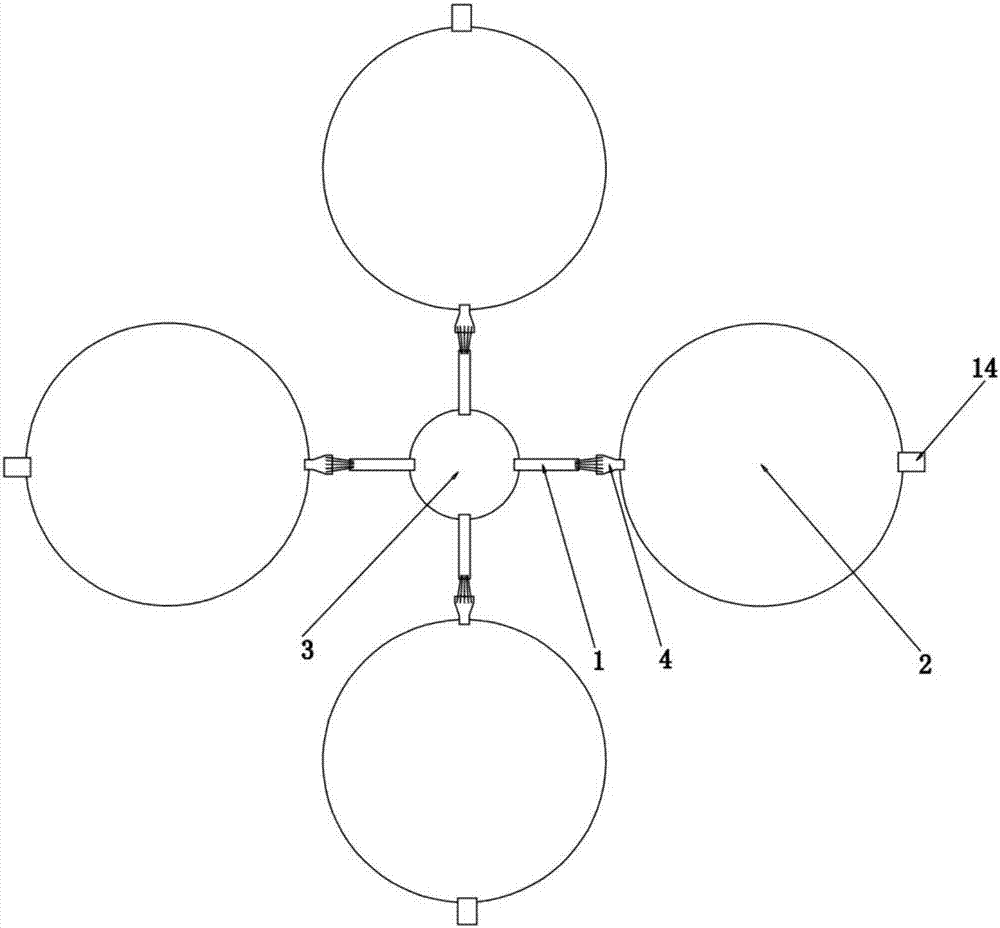

[0025] Such as figure 1 As shown, a biomass pyrolysis gasification furnace with a star-shaped combined structure includes a main furnace 3, and the main furnace 3 is correspondingly connected with at least one auxiliary furnace 2. On the main furnace 3, at least one circular The cylinder connecting pipe 1 is provided with a conical cylinder connecting pipe 4 on the auxiliary furnace 2, and each cylindrical connecting pipe 1 is matched with a corresponding conical cylinder connecting pipe 4. The present invention is a kind of star combination structure The main furnace 3 in the biomass pyrolysis gasification furnace uses biomass energy blocks with high calorific value to generate combustible gas, and the flame generated is used to start multiple parallel auxiliary furnaces 2, so that the types of biomass raw materials in the auxiliary furnace 2 and humidity are changed, and biomass fuel with high water content can be processed without pretreatment. The high-temperature flue gas...

Embodiment 2

[0032] Such as figure 2 As shown, in this embodiment, the similarities with Embodiment 1 will not be repeated. The difference is that in this embodiment, a star-shaped biomass pyrolysis gasifier with a main furnace connected in parallel and four auxiliary furnaces is adopted. It can mainly process a large amount of biomass raw materials.

[0033] The present invention adopts a small-volume main furnace 3, which is connected with four relatively large-volume auxiliary furnaces 2 through connecting pipes to form a star-shaped pyrolysis gasification furnace with one drive and many. Combustion of high calorific value energy blocks in the main furnace 3 generates high-temperature gas, and then respectively ignites the combustible gas in the gap between the cylindrical connecting pipe 1 and the cone connecting pipe 4, thereby starting the annularly connected auxiliary furnace 2. According to the needs of the actual situation, then through the closing of the end caps of the cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com