Gas-liquid separator for plate-type evaporator and plate-type evaporator

A plate evaporator, gas-liquid separator technology, applied in evaporator/condenser, refrigeration and liquefaction, refrigeration components, etc. System cooling effect and other problems, to avoid the reduction of heat exchange efficiency, improve work reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

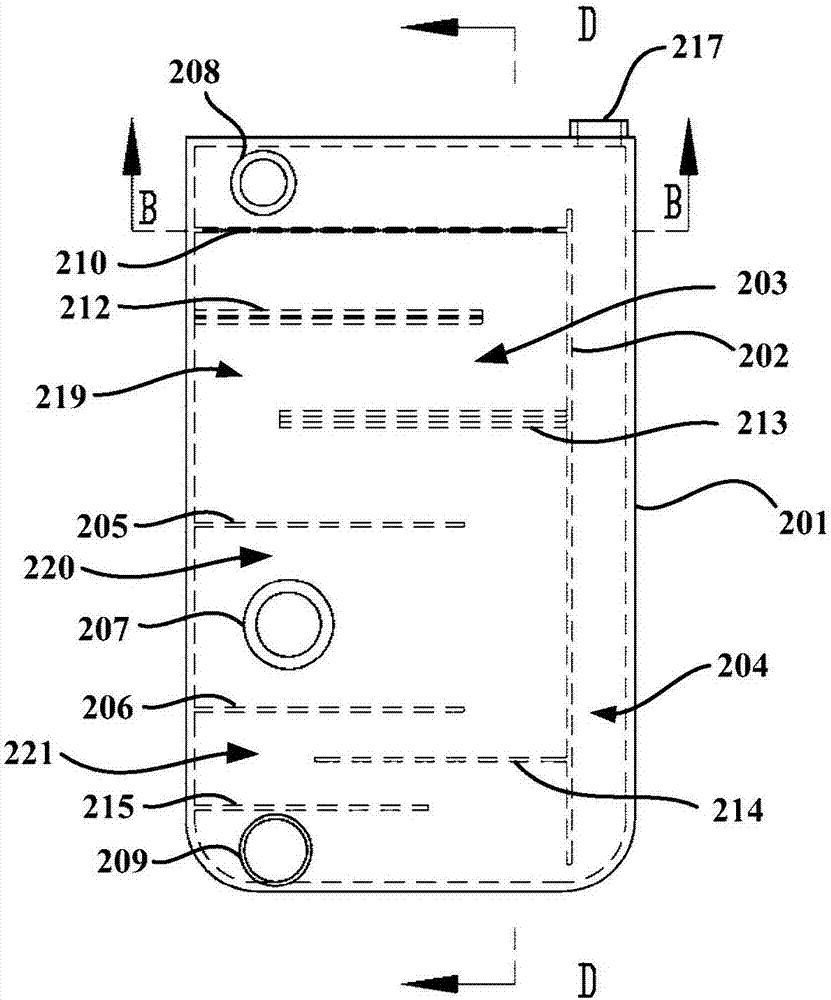

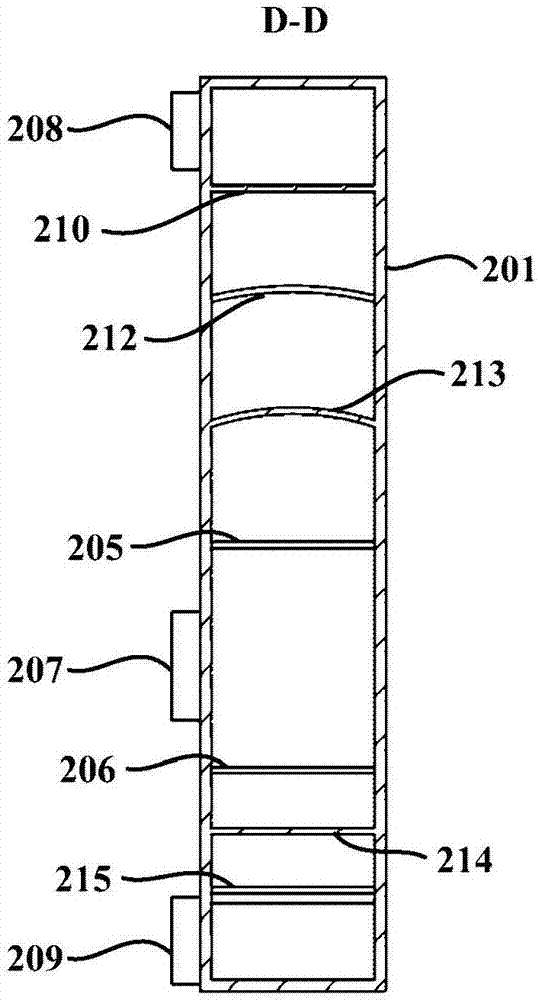

[0028] The refrigerant in the refrigeration system is often a gas-liquid two-phase after being reduced by a throttling device. The gas-liquid two-phase refrigerant flowing into the plate evaporator at the same time will increase the flow rate, and most of the liquid refrigerant is concentrated in the plate evaporator inlet pipe At the end of the evaporator, the gaseous refrigerant is concentrated at the front end of the inlet pipe. When the gaseous refrigerant flows through the evaporator, it not only fails to achieve cooling, but also causes uneven distribution of the liquid refrigerant in the evaporator, reducing the effective heat exchange area of the evaporator , Which seriously affects the heat exchange efficiency of the plate evaporator, and further affects the cooling effect of the entire refrigeration system.

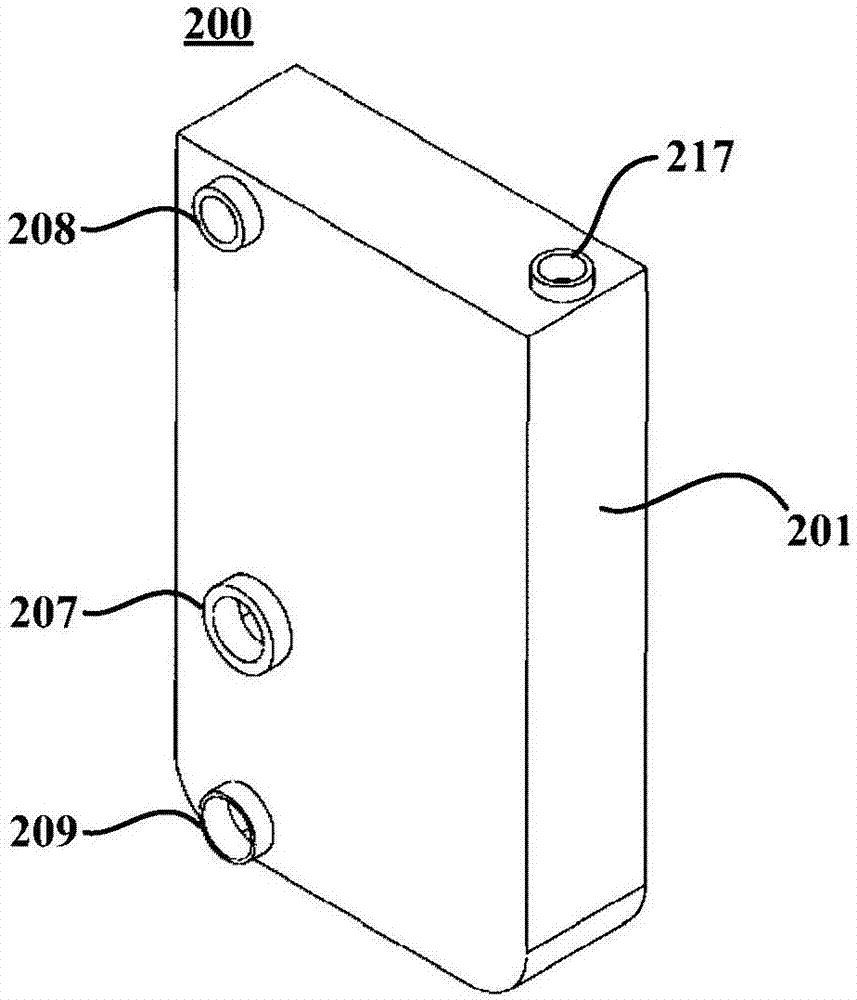

[0029] In order to solve the above problems, this embodiment proposes a gas-liquid separator for a plate evaporator, which can separate the refrigerant after pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com