New process for cooling carbonate beverage mixed liquor through outer ice melting equipment

A carbonated beverage and mixed liquid technology, applied in the field of ice cold storage, can solve the problems of high failure rate, high temperature, shortened life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

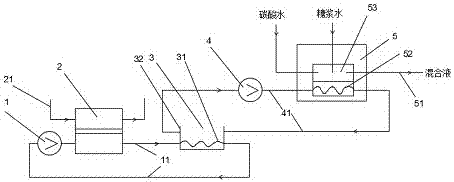

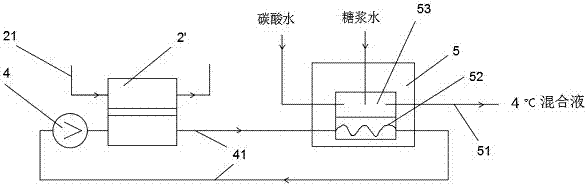

[0019] Such as figure 2 As shown, a new process for cooling carbonated beverage mixed liquid by using external ice-melting equipment, which includes brine pump 1, brine cooler 2, external ice-melting equipment 3, ice water pump 4, mixer 5 (including cooler 52, mixed liquid tank 53), brine circulation pipeline system 11, ice water circulation pipeline system 41, mixed liquid pipeline system 51. The external ice-melting equipment 3 is composed of a metal coil 31 and an open ice storage tank 32 . The low-temperature brine of -6°C is carried in the metal coil pipe 31 pipe, and the outside of the pipe freezes, and the open ice storage tank 32 is ice water of 0~4°C.

[0020] The specific operation steps are as follows:

[0021] The brine chiller 2 is turned on during the low-valley electricity period at night, and the outer metal coil 31 is frozen, and the cooling capacity is stored in the ice storage tank 32 in the form of ice. The ice water pump 4 can adjust the start-stop tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com