Device and method for producing a spring wire, device and method for marking a spring wire, device and method for producing springs from a spring wire, and spring wire

A spring steel wire and equipment technology, applied in the field of spring steel wire, can solve the problems of time and manpower waste, spring steel wire cannot be fully identified or identified, separated, etc., and achieve the effect of marking safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

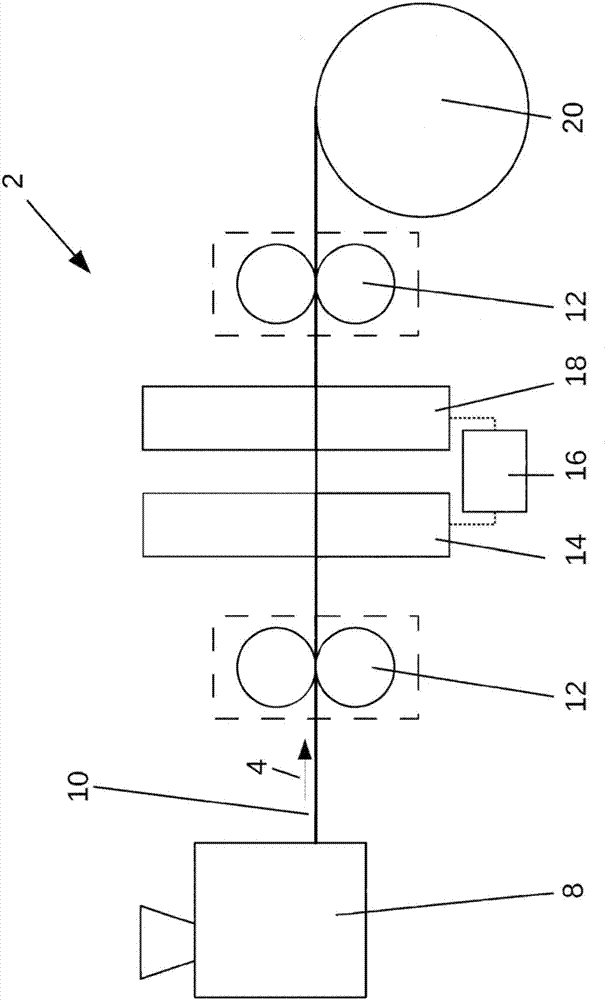

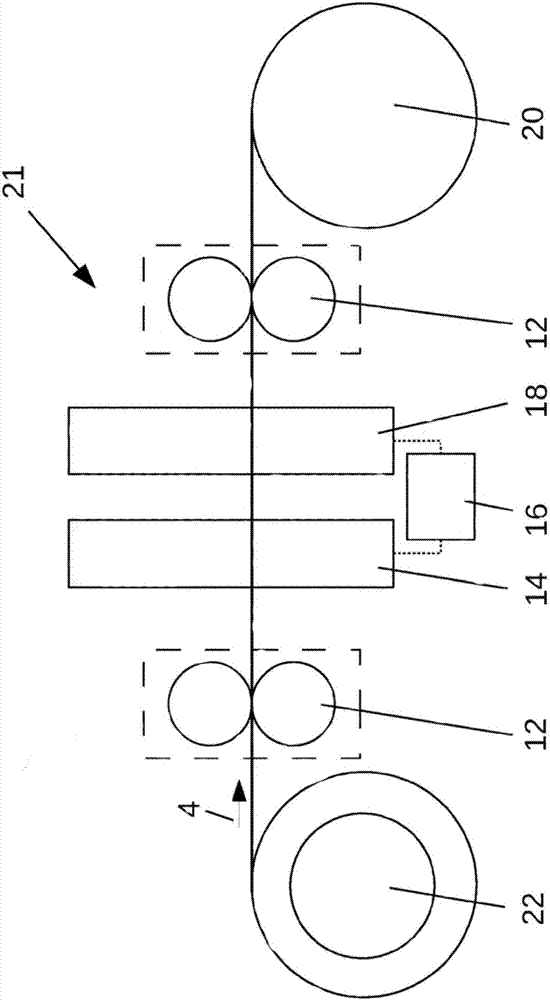

[0106] figure 1 A schematic diagram of a spring wire production plant 2 is shown.

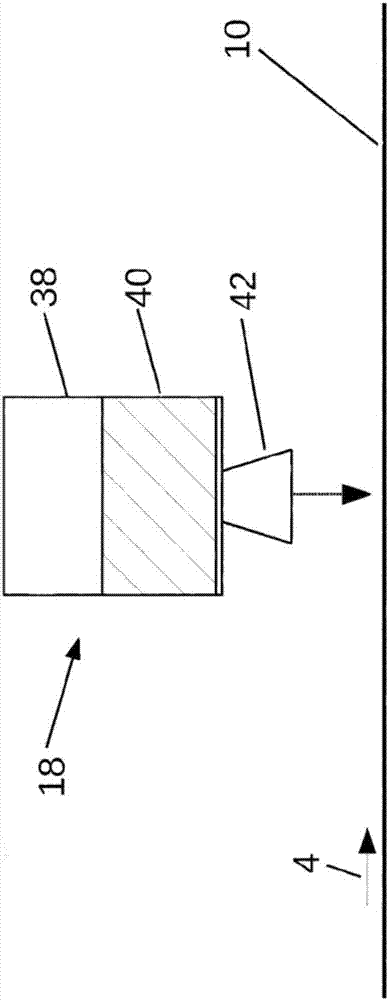

[0107] The spring steel wire production plant 2 comprises a wire production device 8 , a first wire guide 12 , a detection unit 14 , a laser marking unit 18 , a control unit 16 , an additional wire guide 12 and a take-up roller 20 .

[0108] The wire production device 8 is designed such that a spring steel wire 10 can be produced from raw material, in particular by drawing. This is well known to those skilled in the art and does not require a more detailed explanation here.

[0109] Spring steel wire 10 is produced continuously by wire production device 8 and toward figure 1 The right side leaves the wire production device 8 and passes through the first wire guide 12 , the detection unit 14 , the laser marking unit 18 , and the additional wire guide 12 , and finally winds into the take-up roller 20 . The direction of movement of the spring steel wire 10, which is at figure 1 From left to ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com