Synthesis gas washing system adapting to severe working conditions and working method thereof

A synthesis gas and working condition technology, applied in gas dust removal, petroleum industry, combustible gas purification, etc., can solve problems such as downcomer burn-through, quenching water pipeline wear, quenching water filter clogging, etc., to reduce solids, alleviate Clogging and wear problems, solids reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

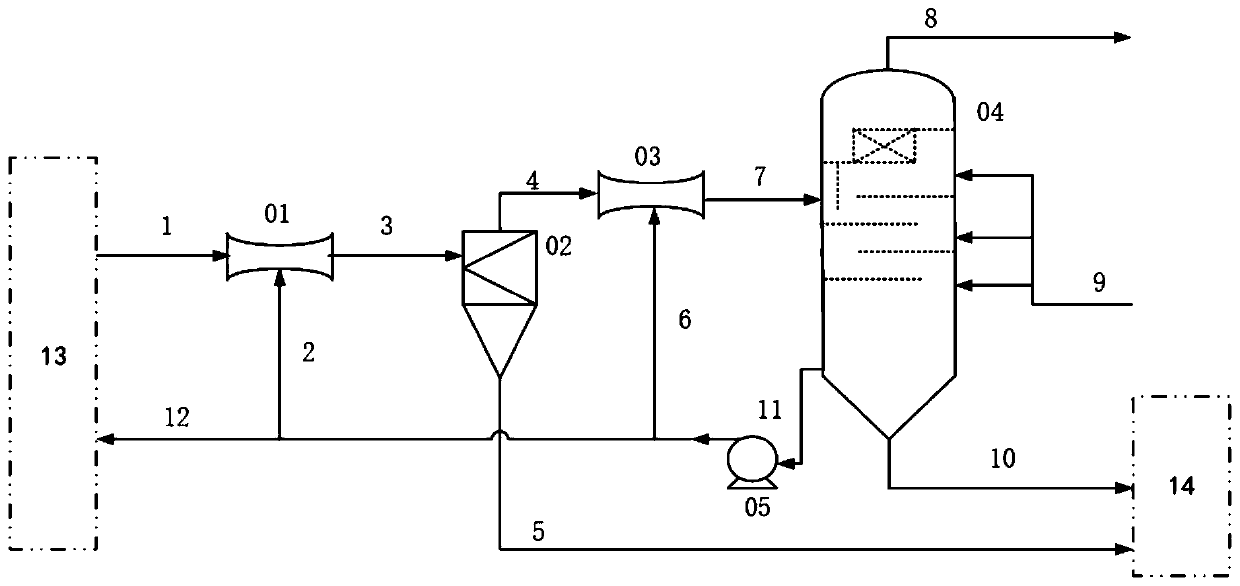

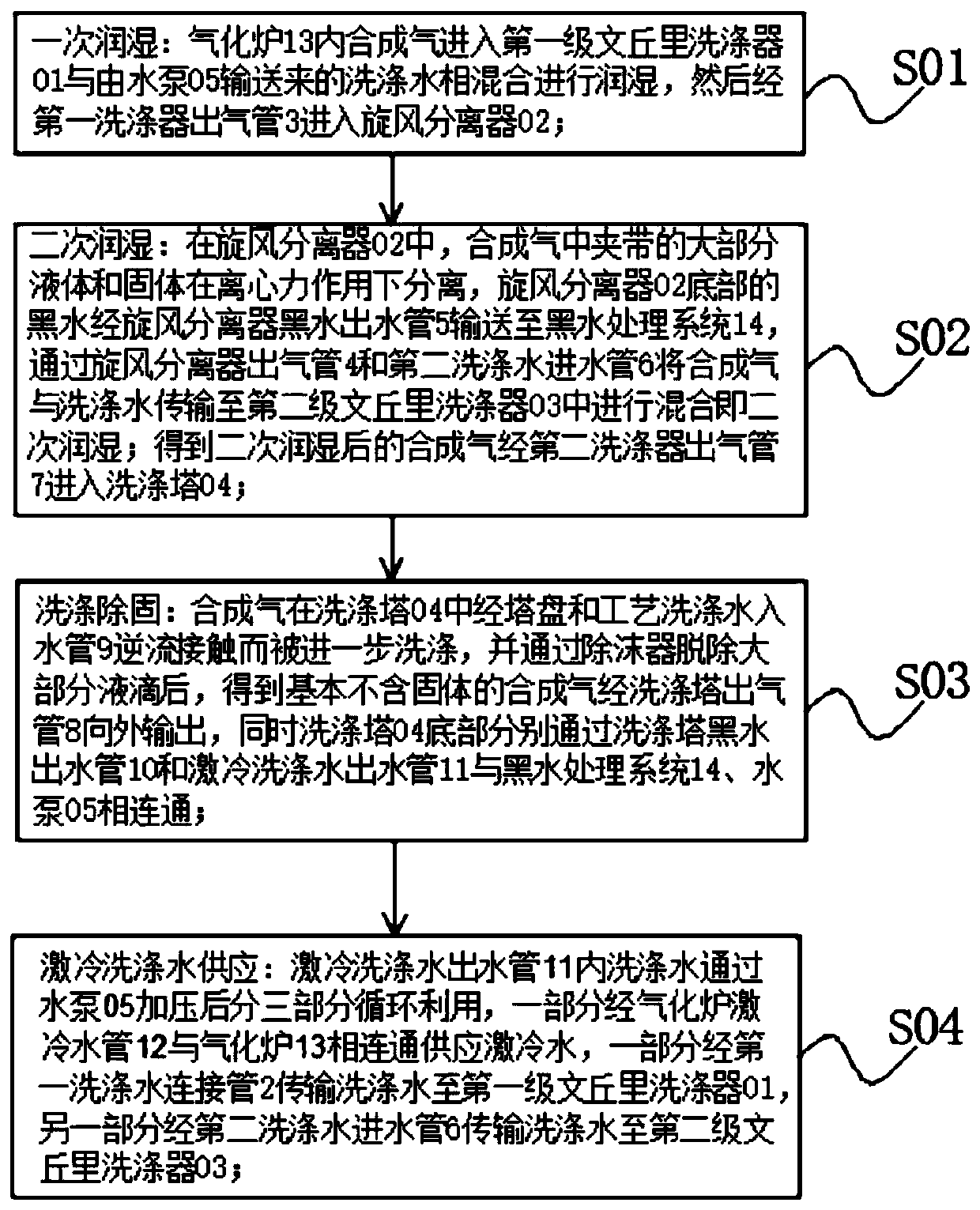

[0039] see figure 1 As shown, a syngas scrubbing system adaptable to harsh working conditions of the present invention includes a gasifier 13, a black water treatment system 14, a first-stage Venturi scrubber 01, a cyclone separator 02, and a second-stage Venturi scrubber Device 03, scrubber 04 and water pump 05;

[0040] The water pump 05 adopts an independent chilled washing water pump; the water pump 05 is used to pressurize the process washing water, and the water pump 05 communicates with the second-stage Venturi scrubber 03 through the second washing water inlet pipe 6, and connects with the second-stage Venturi scrubber 03 through the first washing water connecting pipe 2 It communicates with the first-stage Venturi scrubber 01, and communicates with the gasifier 13 through the quenching water pipe 12 of the gasifier;

[0041] The first-stage Venturi scrubber 01 is used to initially wet the crude syngas from the gasifier 13. Device outlet pipe 3 communicates with cyclon...

Embodiment 2

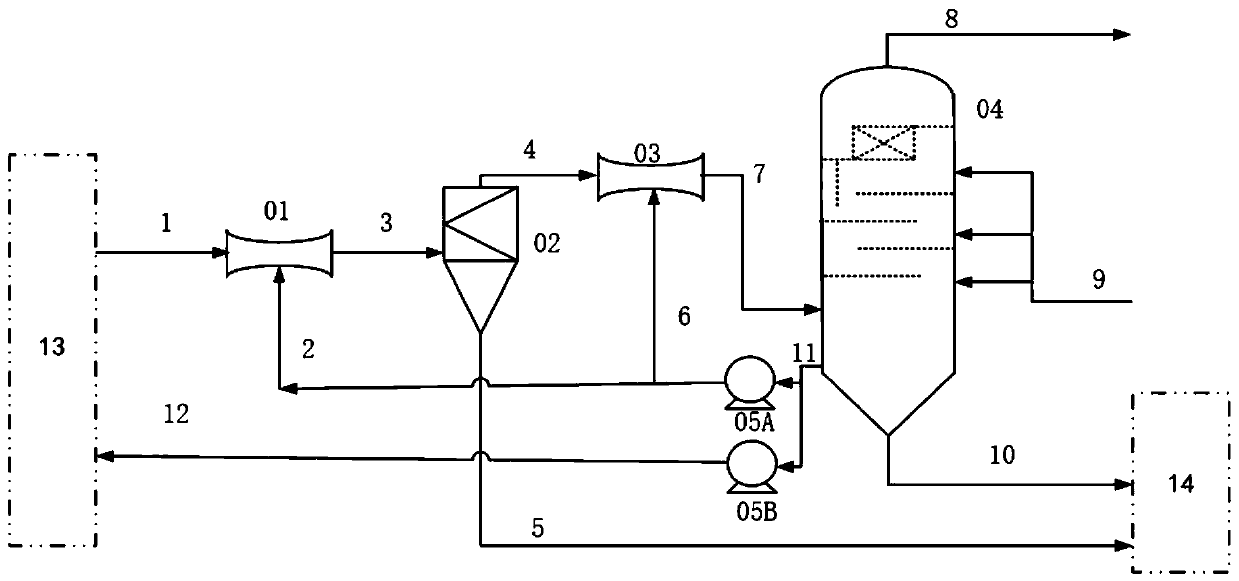

[0055] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the water pump 05 adopts a water pump group composed of a chilling water pump 05A and a washing water pump 05B, and the working method flow is the same as that of Embodiment 1. The black water outlet pipe 5 of the cyclone separator is added The pressure device is connected to the gasifier 13;

[0056] One channel of the chilled water pump 05A is a chilled water pump specially connected to the gasifier 13 to ensure high stability of the chilled water flow; the other channel of the scrubbing water pump 05B is specially connected to the first-stage Venturi scrubber 01 and the second-stage Venturi scrubber 03 wash water pump.

[0057] In this embodiment, the black water outlet pipe 5 of the cyclone separator at the bottom of the cyclone separator 02 is discharged to the black water treatment system 14 for further treatment. Based on the consideration of optimal utilization of system w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com