Chassis with high movement suspension

A technology of chassis and rear suspension, applied in the direction of suspension, elastic suspension, motor vehicle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

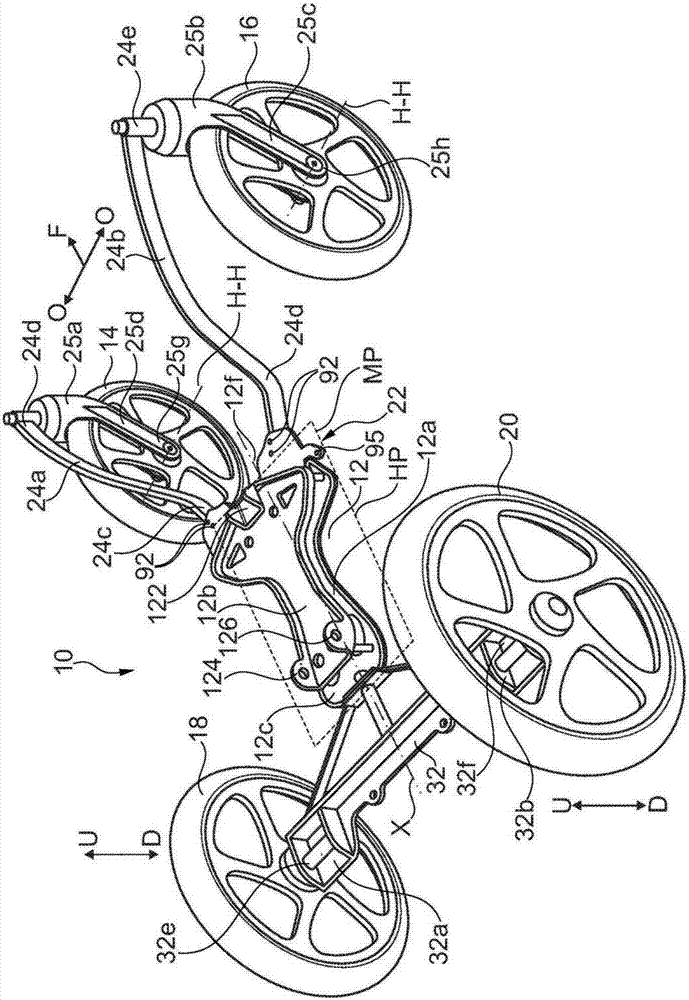

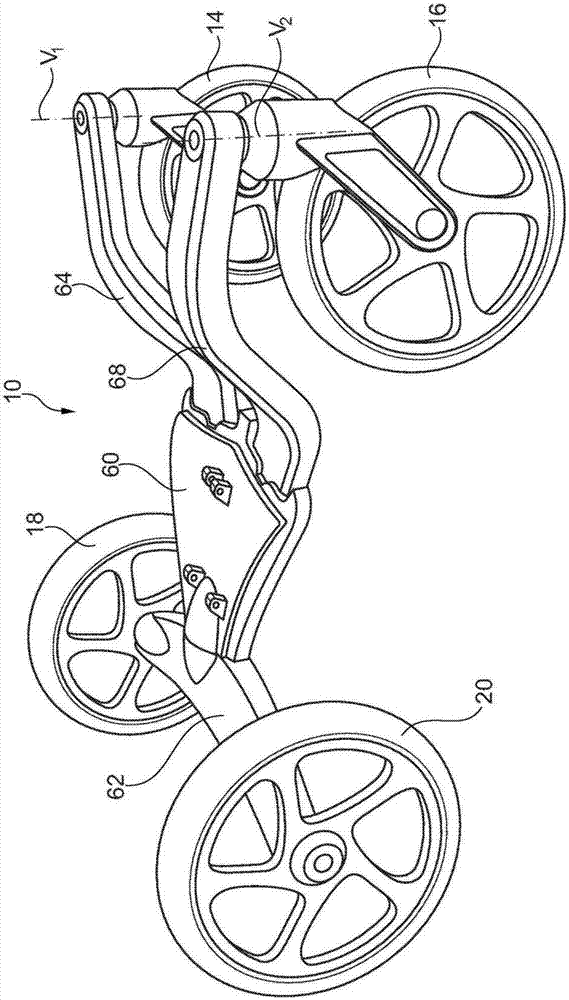

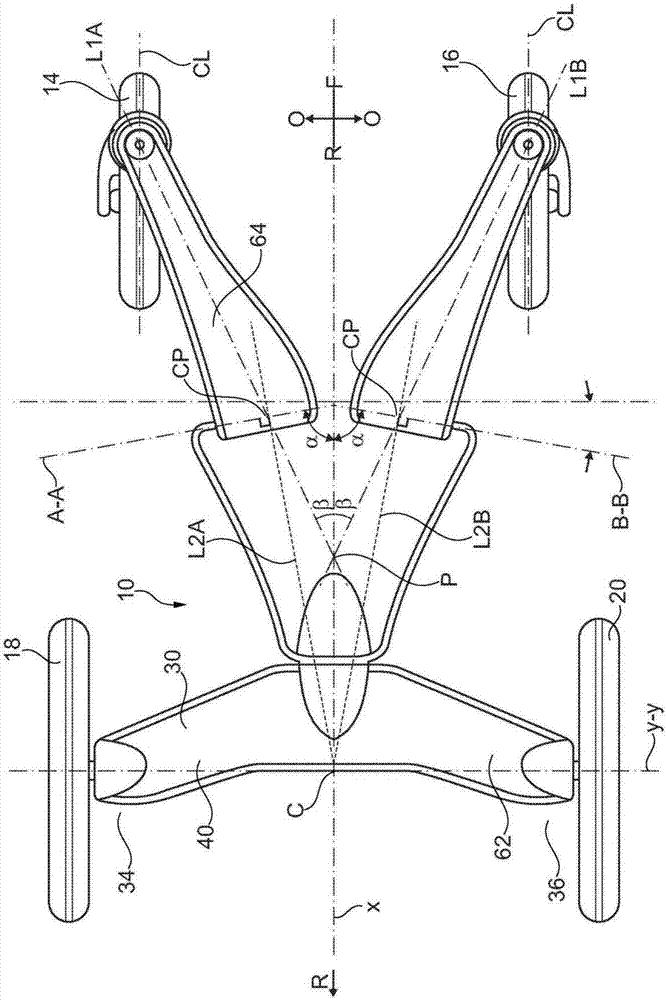

[0032] Reference is now made to the drawings in general, but to the figure 1 , figure 2 and image 3 , a wheeled conveyor device 10 comprising a chassis 12 having a first base member 12a extending in a substantially horizontal plane HP and a longitudinal axis X on which a plurality of wheels 14, 16, 18, 20 lie Around this longitudinal axis X is mounted a suspension system generally designated 22 . Suspension system 22 includes one or more front arms 24a and 24b extending from front portion 12f of chassis 12 in a generally forward direction F and outward O, and each wheel is included herein at its distal end 24d, 24e The caster arrangements 14, 16 are discussed in more detail below. Arms 24a, 24b are each mounted for substantially vertical pivotal movement V about axis A-A or B-B, as image 3 As best shown in , each axis extends at an acute angle with respect to the longitudinal axis X and, in one arrangement, preferably also extends in or parallel to the horizontal plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com