Double-column-cage large-diameter prefabricated tubular pile

A prefabricated pipe pile and large-diameter technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of deflection, deflection or displacement of circular stirrups, affecting the production quality of large-diameter prefabricated pipe piles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

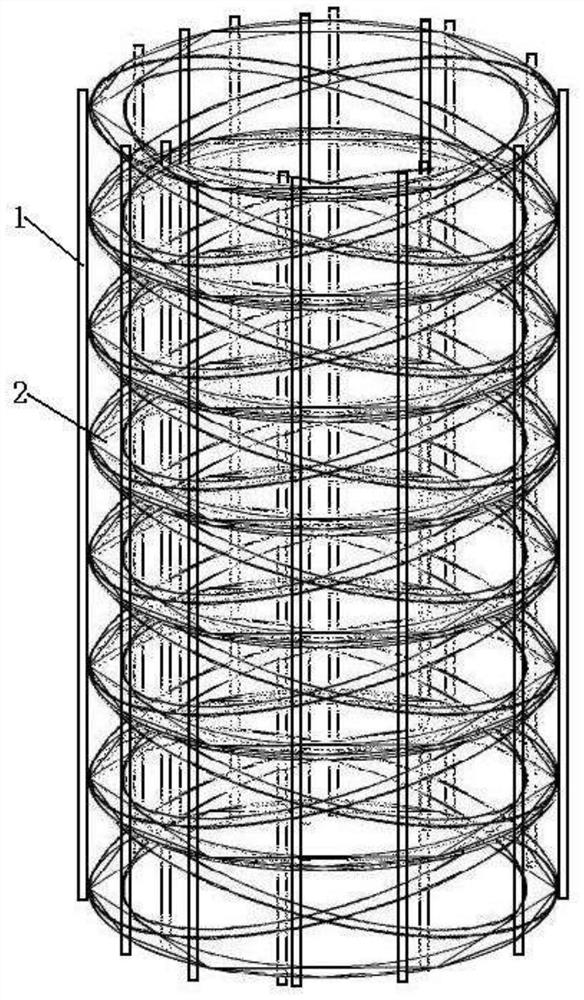

[0042] As shown in the figure, to make a large-diameter prefabricated pipe pile with a double-column cage, first make a double-fork elliptical inner and outer hoop column 2, then stack several double-fork elliptical inner and outer hoop columns 2 up and down, and then stack the double-fork elliptical inner and outer hoop columns 2 The steel bar 1 of the connecting column is fixed on the inner and outer hoop column 2 of the ellipse to form a double-layer reinforcement column cage with an inner layer hoop column and an outer layer hoop column, and then the installation piles are fixed at both ends of the double-layer reinforcement column cage according to common methods Then install the centrifugal steel formwork, then pour concrete, after centrifugal compaction, curing and formwork removal, a double-column cage large-diameter prefabricated pipe pile is obtained.

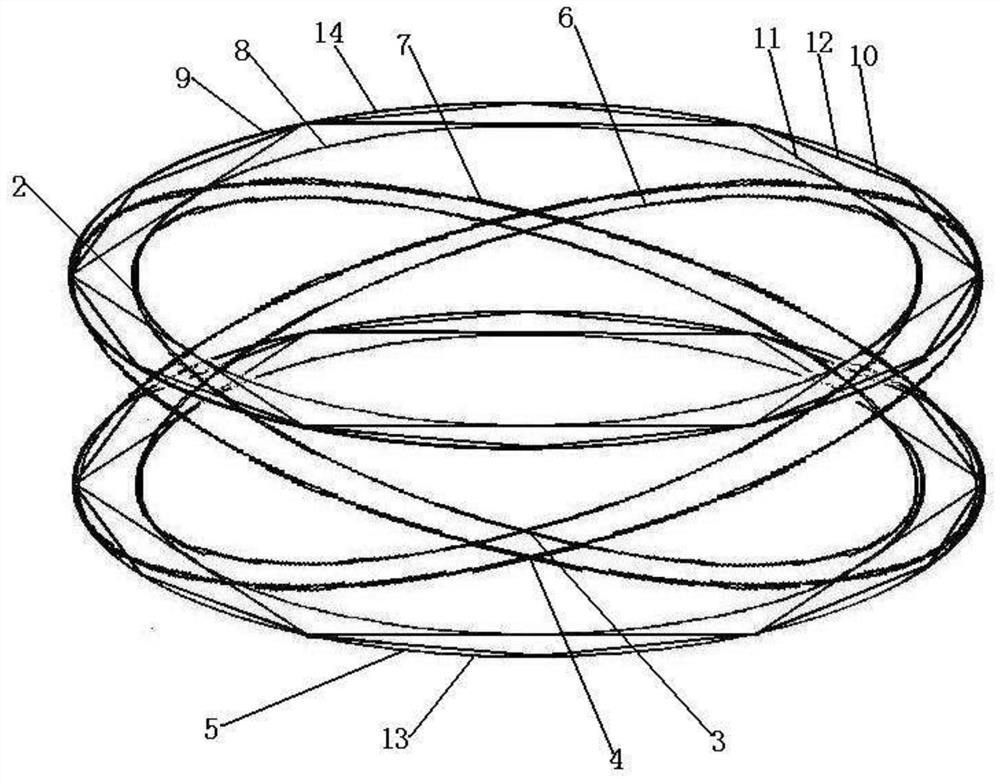

[0043] The double-fork elliptical inner and outer hoop columns 2 include a set of inner fork elliptical stirrups 3, ...

Embodiment 2

[0056] A method for manufacturing a large-diameter prefabricated pipe pile with a double-column cage, comprising the following steps:

[0057] ⑴Prepare concrete, column steel bar 1, bar steel bar, binding steel wire and pile head plate according to the design requirements.

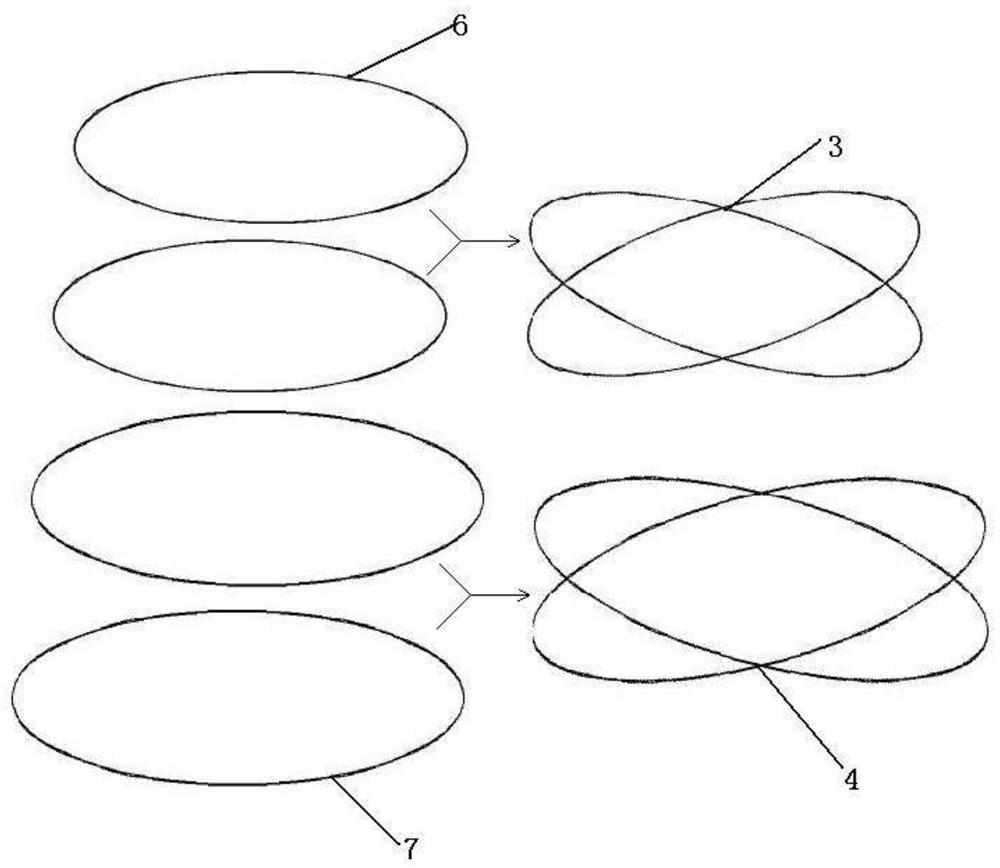

[0058] (2) Make several outer circular stirrups 9 with steel bars according to the design requirements, and then the radius length R of the outer circular stirrups 9 and the included angle A between the plane where the large major axis ellipse 7 is located and the plane where the circular stirrup 5 is located As a benchmark, make several inner circle stirrups 8, large major axis ellipse 7, small major axis ellipse 6 and temple top triangle 10 with bar steel bar. Set the inner 9 of the outer circular stirrup to install n end-to-end closed-loop side brace top triangles 10; then the radius length of the inner circular stirrup 8 is made into R cos (360 / 2n), and the large major axis ellipse 7 The short axis is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Major axis length | aaaaa | aaaaa |

| Major axis length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com