Multi-level hand apparatus and conveying robot provided with the same

A multi-layer, hand-holding technology, applied in the direction of robots, conveyors, manipulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Preferred embodiments of the present invention will be specifically described below with reference to the drawings.

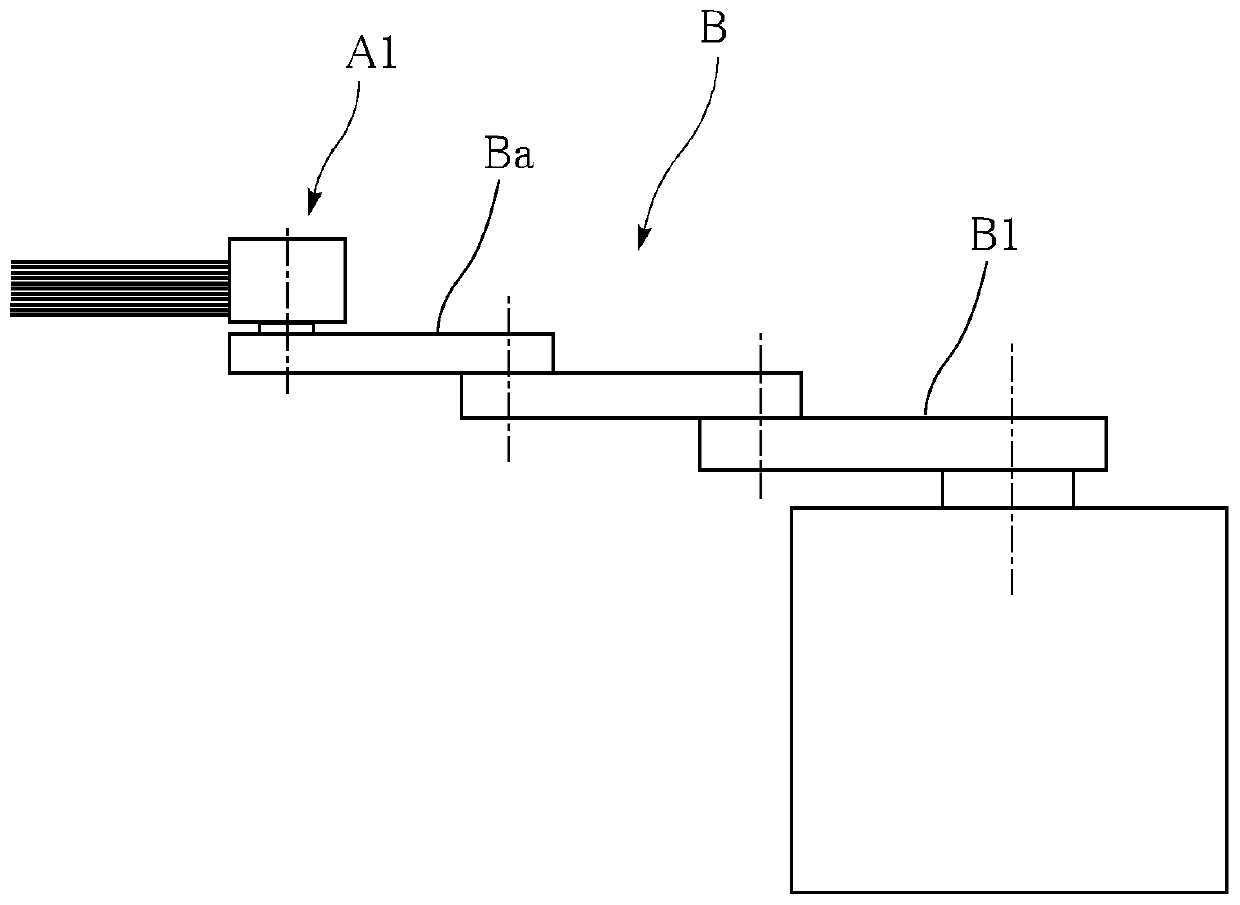

[0055] Such as figure 1 As shown, the multi-layered support A1 according to the present invention is mounted on, for example, an effector arm Ba of an articulated robot B1 to form a transfer robot B. As the transfer robot B, a transfer robot having any structure that controls the attitude of the tip of the actuator-equipped arm Ba to move it three-dimensionally can be used.

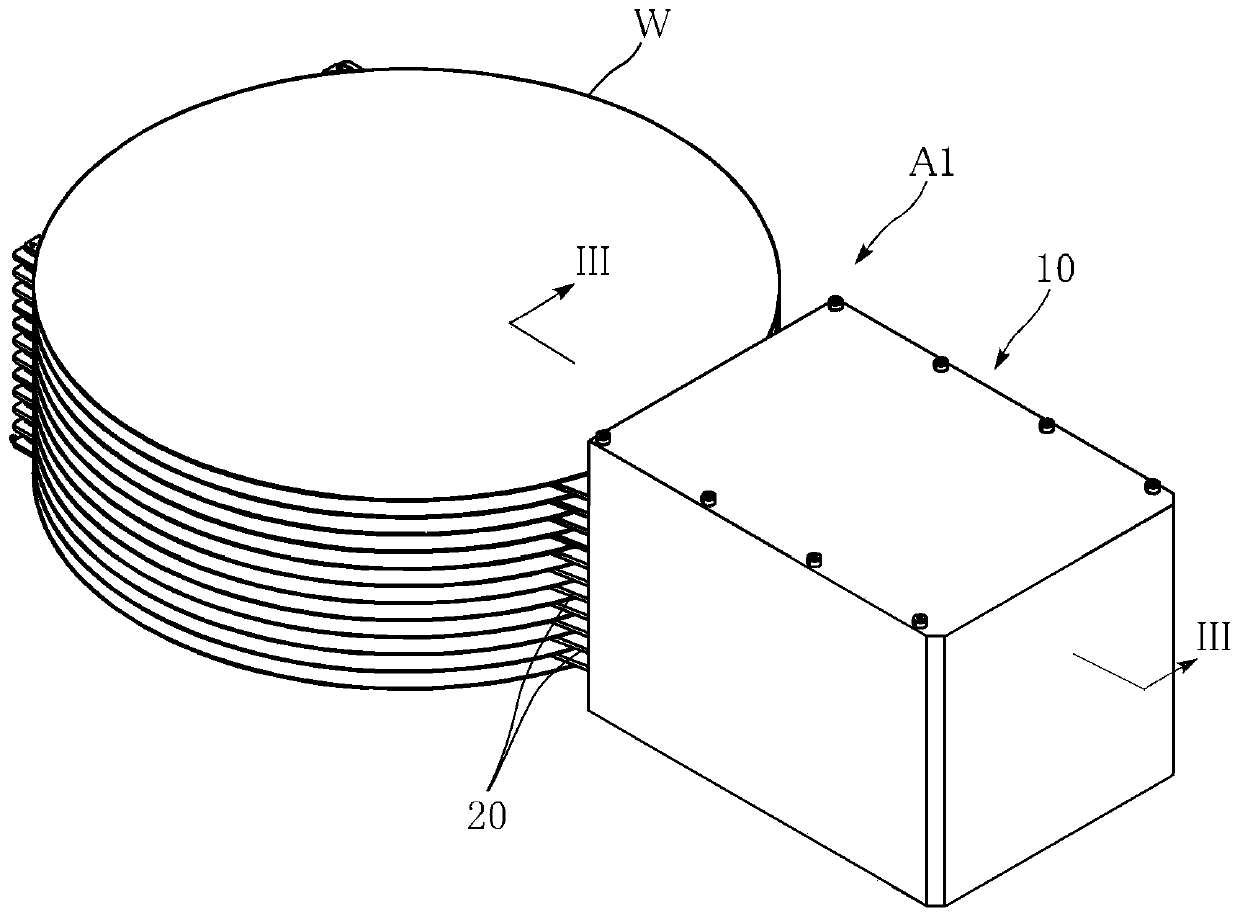

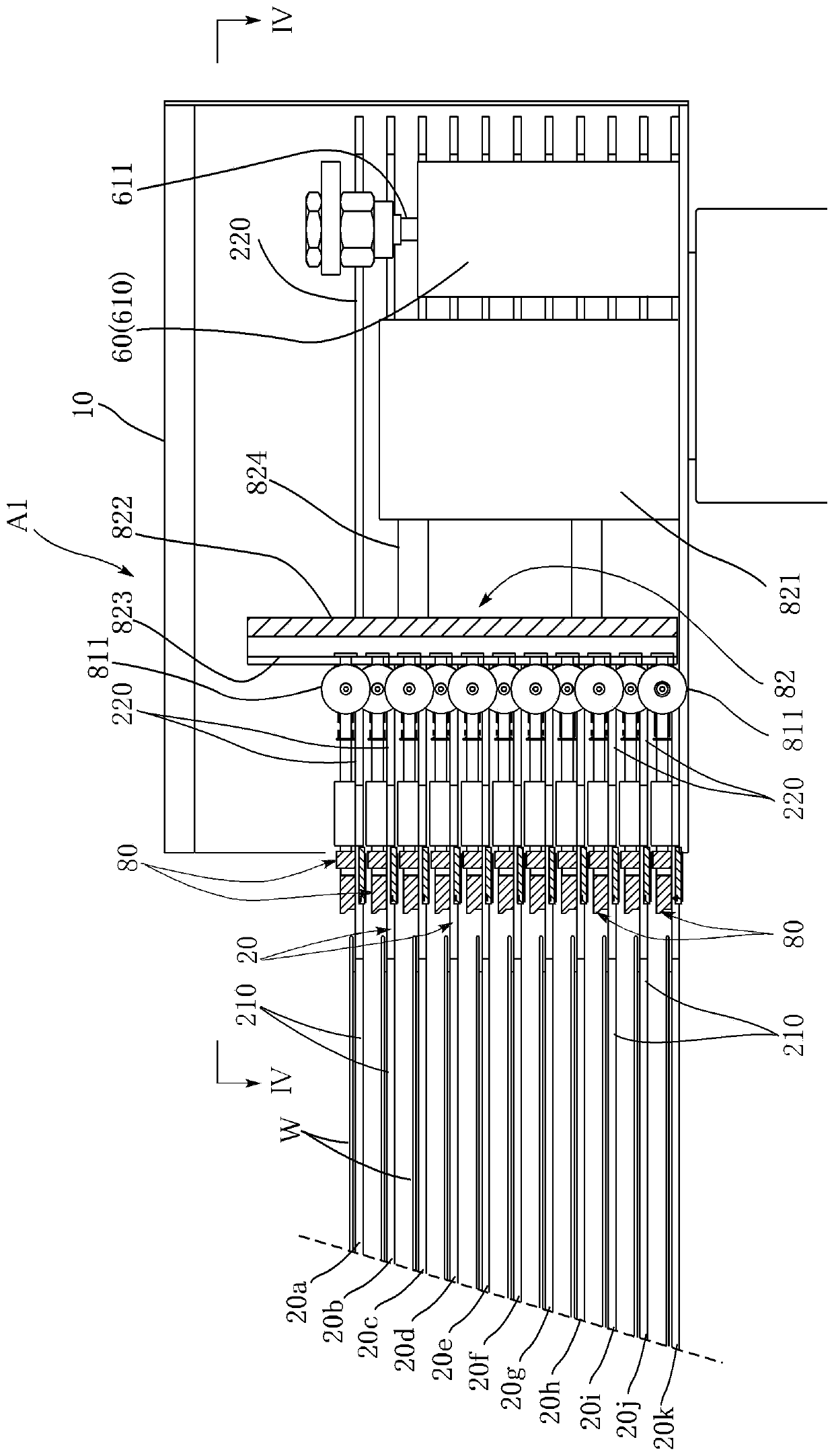

[0056] Figure 2 to Figure 9 Shown is a multi-layered handle A1 according to one embodiment of the present invention. This multi-layered holder A1 has: a storage box 10; a plurality of holders 20 arranged to overlap up and down; a guide unit 70 ( Figure 4 , Figure 9 ); The space constraint unit 50 ( Figure 9 ); and the lifting mechanism 60 that makes the handle (the first handle 20a) of the uppermost position lift.

[0057] In this embodiment, the holder 20 is configured to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com