Breathable polyurethane hotmelt adhesive

A hot-melt adhesive and crystalline polyester technology, applied in the direction of polyurea/polyurethane adhesive, adhesive type, adhesive, etc., can solve the problems of low initial strength, difficult to determine the difference, etc., and achieve low application viscosity , short storage time, avoid delamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

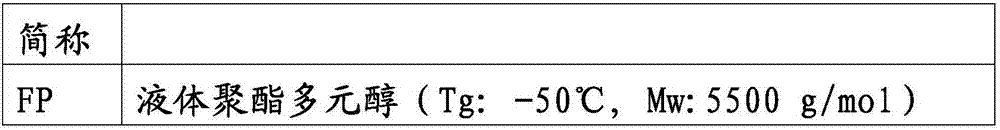

[0083] The following products were used in the test

[0084]

[0085]

[0086] The hot melt adhesives according to Examples B1-B4 and Comparative Examples VB1-VB9 were prepared according to the following general preparation procedures using the parts by amounts given in Table 1 below. In Table 1, parts by weight are expressed in % by weight, based on the total weight of all starting components. When the corresponding components were not used for the preparation in the relevant test, of course no corresponding addition or corresponding step is required. The effects of catalyst amount, reaction ratio, filler amount, types of various polyols and polypropylene glycol were especially studied in the tests. Table 1 also shows the NCO / OH-ratio (NCO / OH) of the starting formulations.

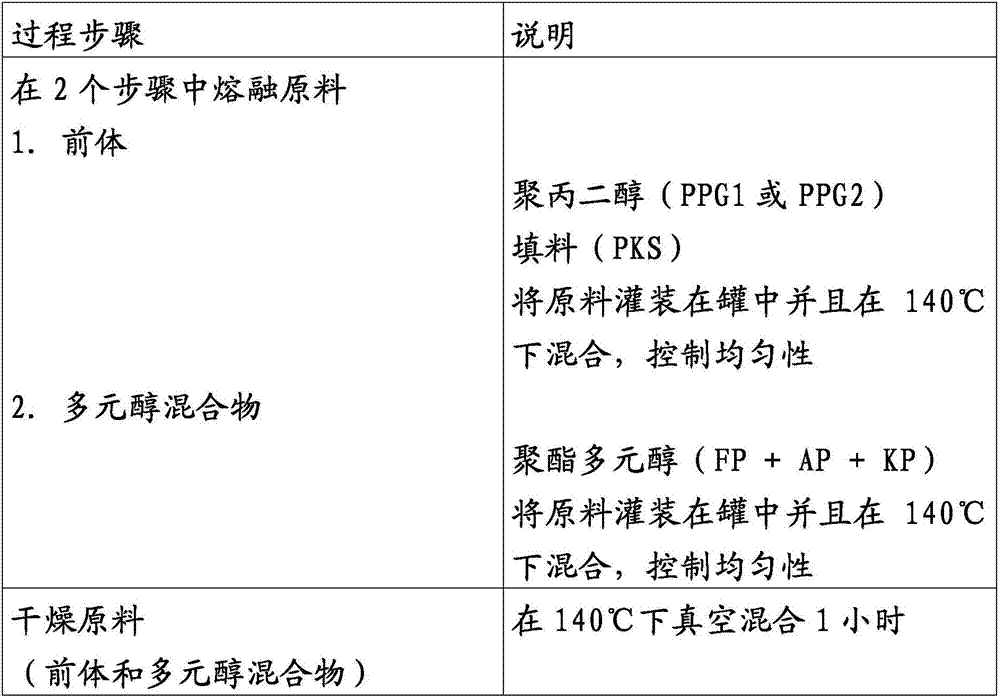

[0087] General preparation process

[0088]

[0089]

[0090] Additional additives (Add), if used, can be added together with the catalyst (in the last preparation step).

[0091] The obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com