Internal-combustion engine piston ring, process for obtaining piston ring, and internal-combustion engine

A technology for piston rings and internal combustion engines, which is applied to piston rings, engine seals, mechanical equipment, etc., and can solve problems such as contact pressure deterioration and increased air pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

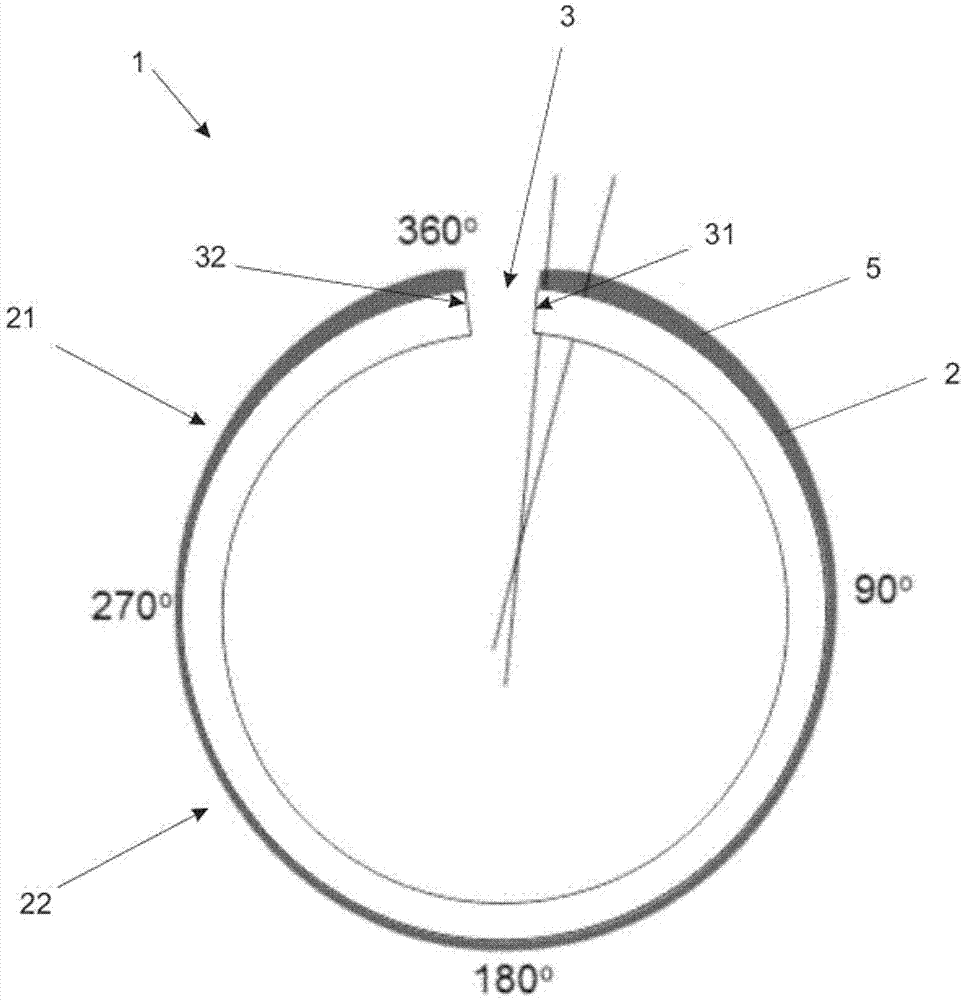

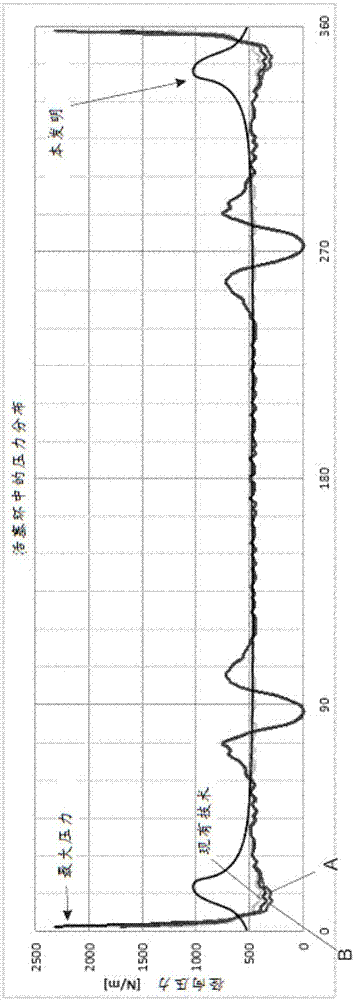

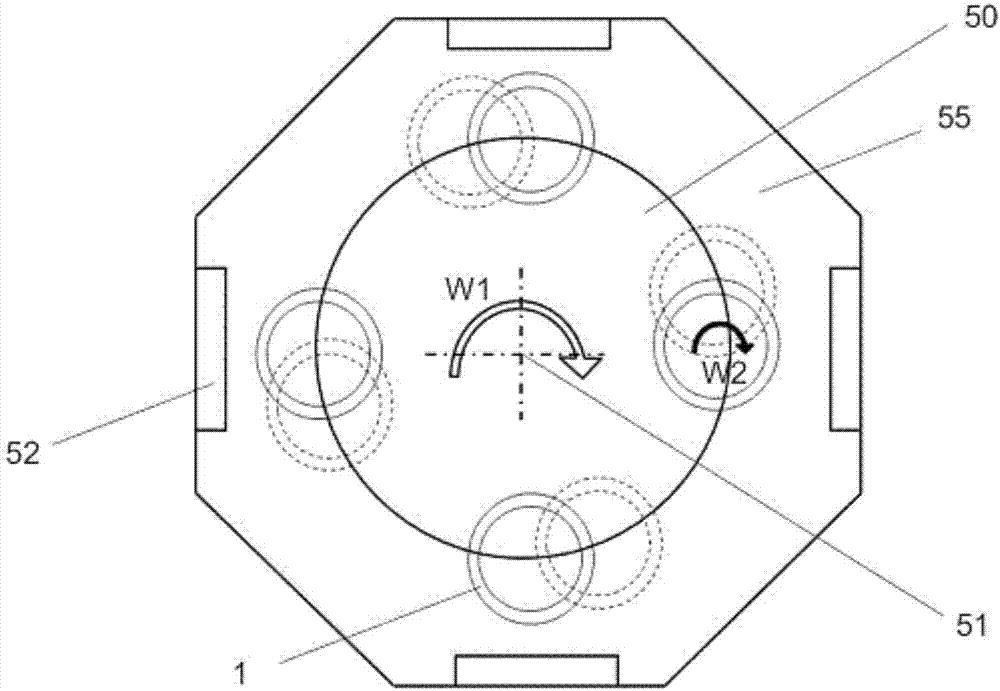

[0029] The invention relates to a piston ring 1 and a method for depositing a coating capable of ensuring a variable thickness of the coating 5 on the outer surface 2 of the piston ring 1 such that at the ends of the gap 3 of the ring 1 In the area adjacent to the parts 31, 32 there is a coating 5 which is thicker than the coating in the opposite area near the ends 31, 32 of the ring 1, in addition, the ends 31, 32 of the gap 3 of the ring 1 are lowered. The thickness of the coating 5 in the vicinity thus provides a piston ring 1 with a high level of durability due to good resistance in the areas of greatest wear of the ring and a high level of thickness.

[0030] As is also known, the entire piston ring 1 is provided with a gap 3 , the presence of which ensures the possibility of mounting the ring in the groove of the piston of an internal combustion engine. For the purpose of better defining the present invention, the area of the gap 3 of the ring is delimited by two ends ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com