Connection arrangement comprising a hydraulic connection element

一种连接元件、连接组件的技术,应用在连接组件,内燃机上的装置领域,达到改善工作方式、节省构件、减小噪声的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

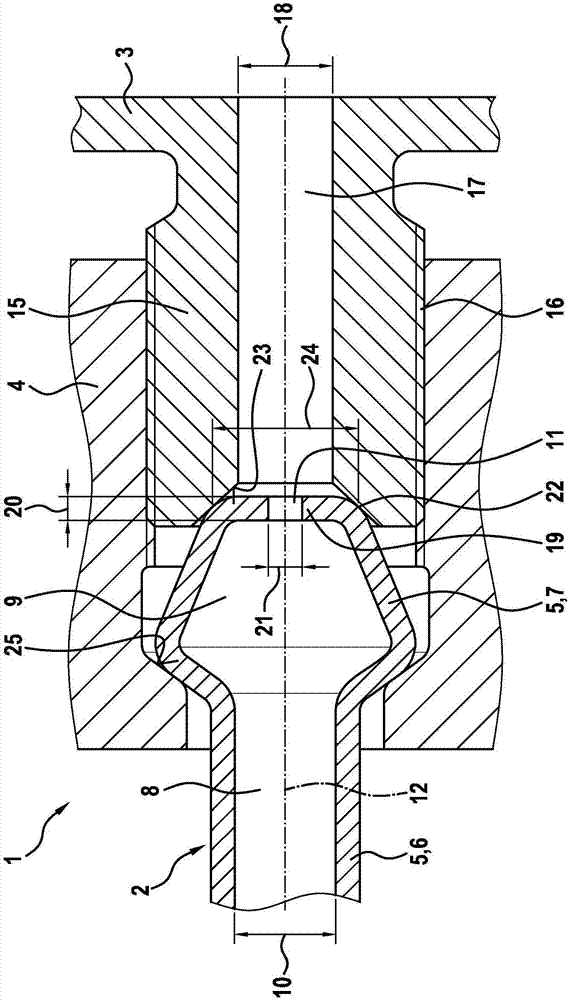

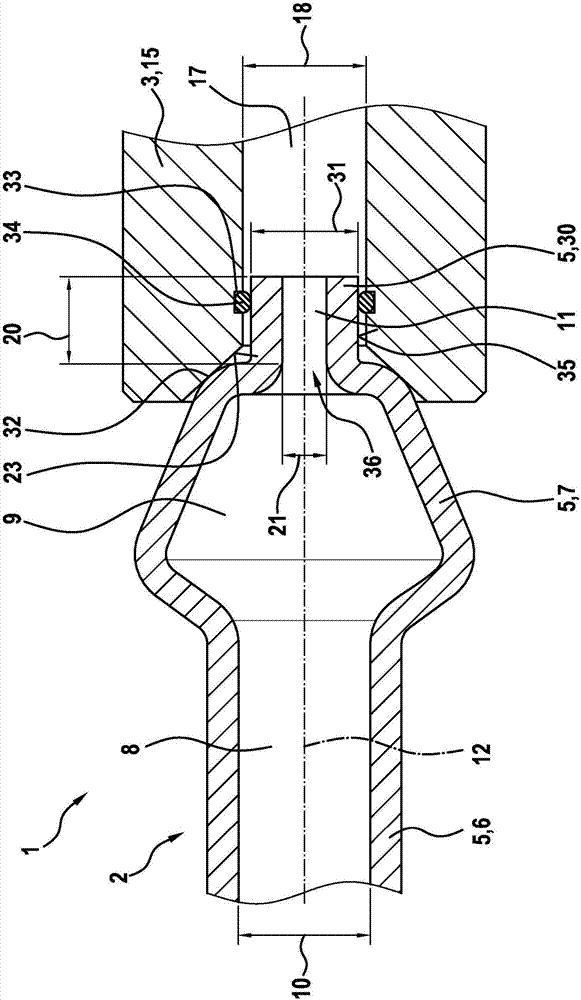

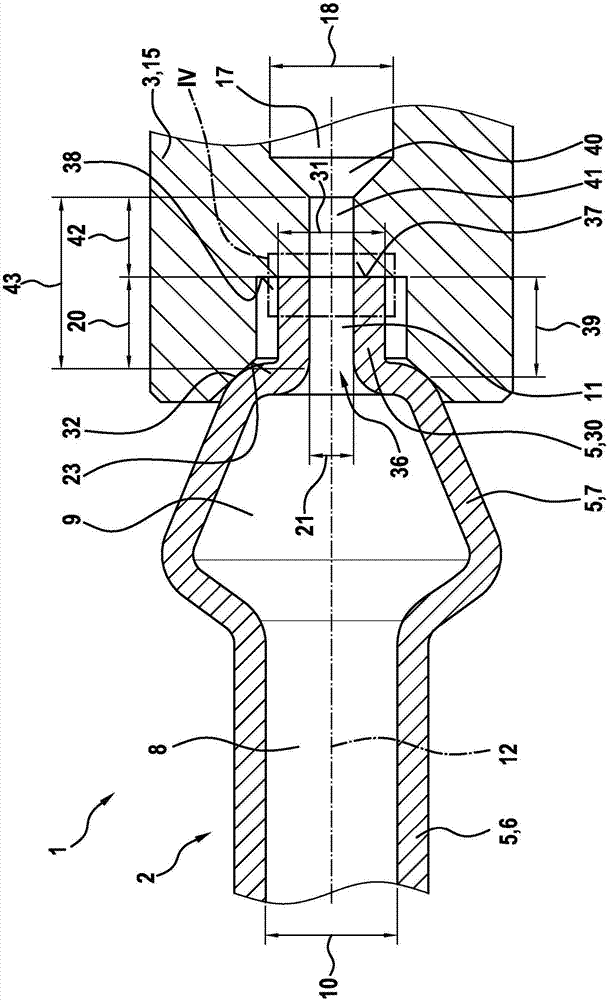

[0023] figure 1 Corresponding to the first exemplary embodiment, a connection assembly 1 is shown in a schematic axial section with a hydraulic connection element 2 and a hydraulic connection piece 3 . In this exemplary embodiment, fastening means 4 are also provided in order to pretension the connection.

[0024] The connection assembly 1 is particularly suitable for installation on internal combustion engines. In particular fuel can be conducted here via the hydraulic connection element 2 and the hydraulic connection piece 3 . However, the connection assembly 1 is also suitable for other applications using hydraulic media.

[0025] The hydraulic connection element 2 has a base body 5 with a pipe 6 and a tulip 7 attached to the pipe 6 . During production, the tulip-shaped part 7 can be formed in a suitable manner from the tubular base body 5 . A channel 8 in the form of a hole 8 is formed in the tube 6 , to which channel the interior 9 of the tulip-shaped part 7 is attach...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap