Side-coated heat shield element with impingement cooling at exposed surfaces

A technology of heat shielding and components, which is applied in the field of manufacturing heat shielding components and heat shielding devices, can solve problems such as damage to the uniform distribution of cooling air, achieve cost-effective, avoid peeling, and achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

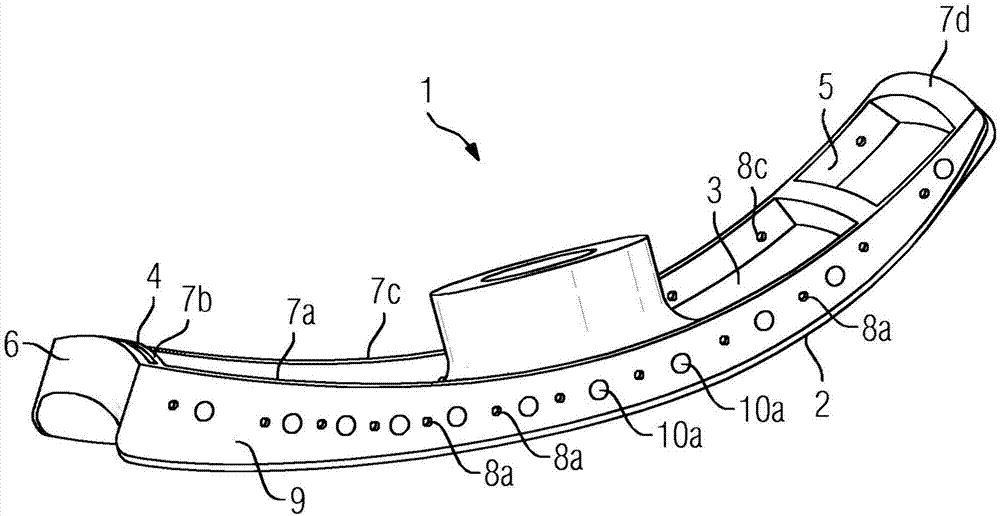

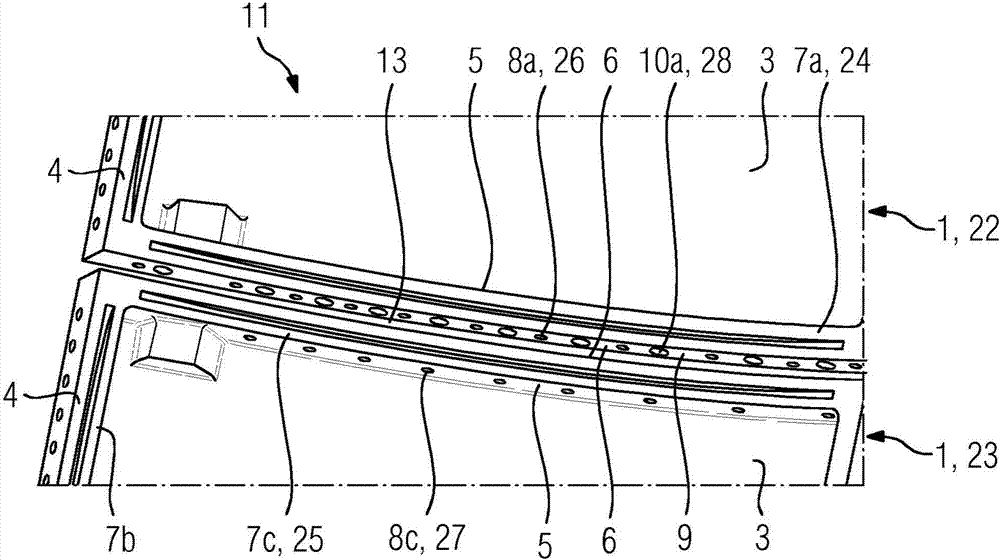

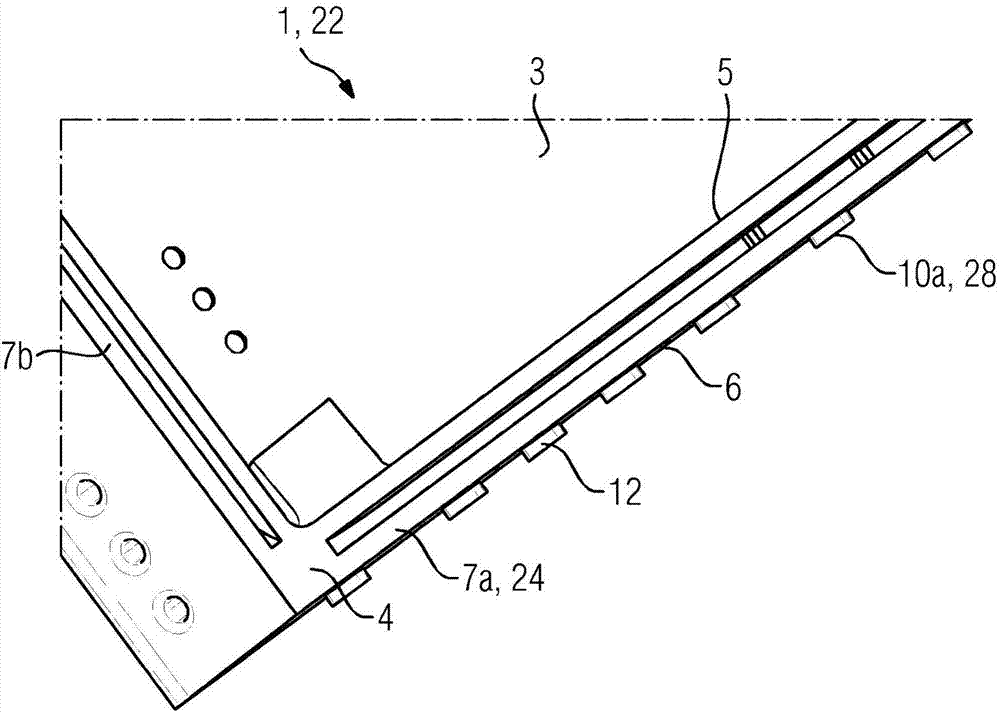

[0036] figure 1 A first exemplary embodiment for a heat shield element 1 according to the invention is shown schematically and by way of example. The heat shield element 1 is substantially metallic, ie it comprises a metal body. It has a hot side 2 that can be exposed to the heat medium and a cold side 3 opposite the hot side 2 . Adjacent the hot side 2 and the cold side 3 is a peripheral edge 4 extending beyond the face of the cold side 3 with an inner side 5 and an outer side 6 and a plurality of edge sections 7a, 7b, 7c and 7d. In the rim 4 , cooling air openings 8 a are arranged in the rim section 7 a and cooling air openings 8 c are arranged in the rim section 7 c , each extending from the inner side 5 to the outer side 6 . The arrangement of the cooling air openings 8a, 8c is selected such that the cooling air opening 8a of the edge section 7a is arranged offset relative to the cooling air opening 8c of the opposite edge section 7c. According to the invention, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com