A multiple-winding motor drive and control mechanism

一种多绕组、电动机的技术,应用在电动机控制、交流电动机控制、控制系统等方向,能够解决少开关次数、PWM载波低次谐波残留等问题,达到高精度电压相位的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

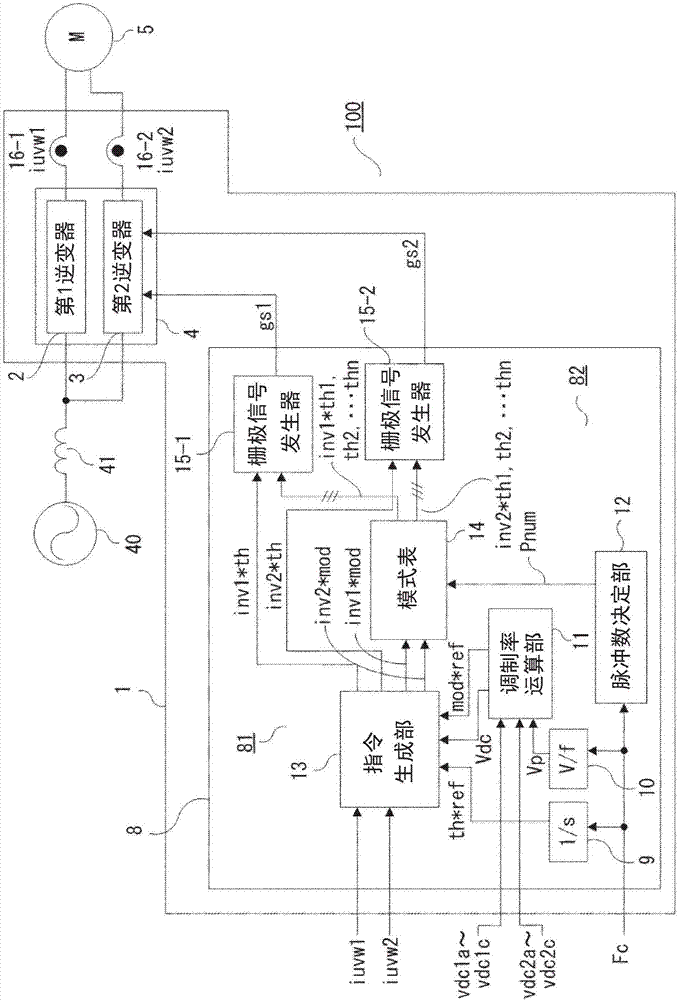

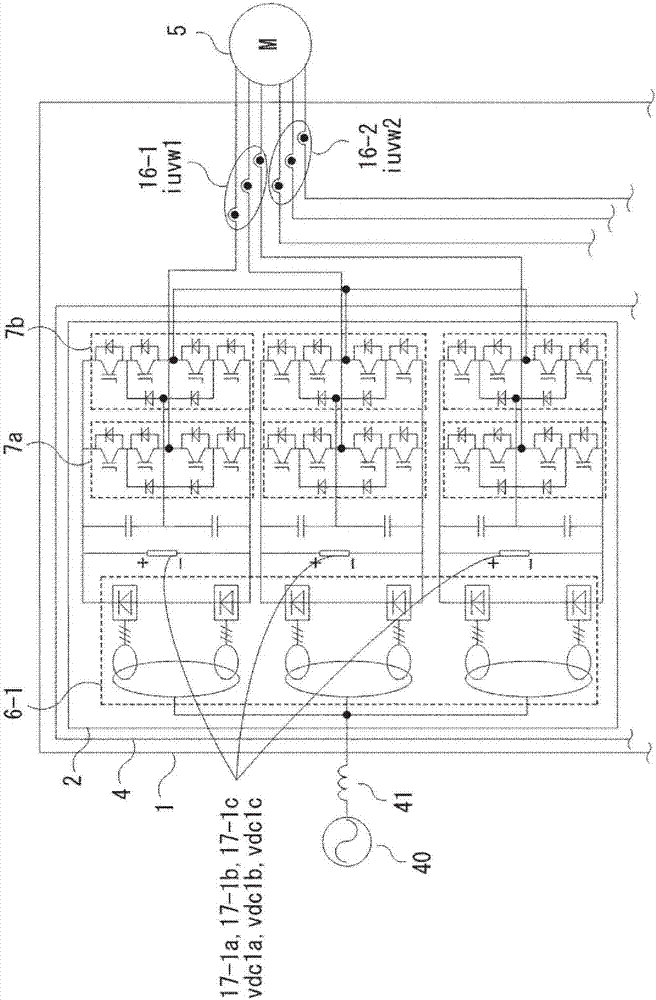

[0038] Embodiment 1 relates to the following multi-winding motor drive control device: the control unit includes an output voltage control unit and a PWM control unit, and the output voltage control unit includes an output voltage determination unit, an output voltage phase calculation unit, and an output voltage phase calculation unit based on the current of the inverter. Modulation rate and phase correction amount used to equalize the current flowing in each winding of a multi-winding AC motor, and generate a modulation rate command and a phase command for controlling the inverter based on the modulation rate and phase command generation unit, PWM control The unit includes: a modulation rate calculation unit; a pulse number determination unit that determines the number of pulses per half cycle in PWM control according to a frequency command; a pattern table that stores switching patterns that reduce low-order harmonics of the output voltage; and A gate signal generator that g...

Embodiment approach 2

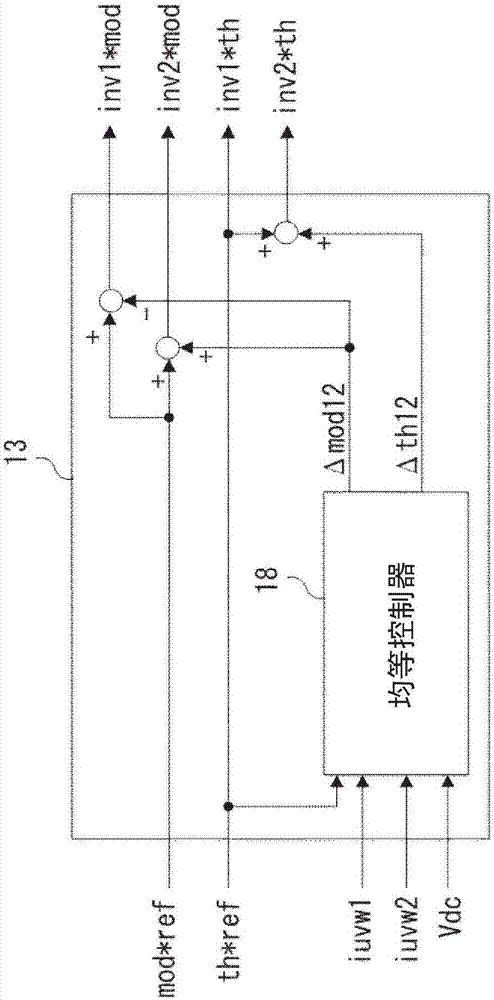

[0147] The multi-winding motor drive control device according to Embodiment 2 sets a current reference value and controls the current of each inverter so that it matches the current reference value, thereby equalizing the current flowing to each winding of the multi-winding AC motor. .

[0148] The following is based on the configuration diagram of the modulation factor phase command generator Figure 10 And as a configuration diagram of the current equalization controller Figure 11 Next, the configuration and operation of the multi-winding motor drive control device according to Embodiment 2 will be described focusing on differences from Embodiment 1. FIG. exist Figure 10 and Figure 11 in, with image 3 and Figure 4 The same or equivalent parts are marked with the same symbols.

[0149] In addition, in the description of Embodiment Mode 2, the diagrams explained in Embodiment Mode 1 will be appropriately referred to.

[0150] The configuration of the multi-winding mo...

Embodiment approach 3

[0185] The multi-winding motor drive control device according to Embodiment 3 uses one inverter as a reference power converter, and controls it so that the current of other inverters matches the current of the reference power converter, thereby making the The current of each winding of a multi-winding AC motor is equal.

[0186] The following is based on the overall configuration diagram of a multi-winding motor drive control device Figure 12 and Figure 13 , as a configuration diagram of the modulation factor phase command generator Figure 14 and Figure 17 , and as a configuration diagram of the current equalization controller Figure 15 , Figure 16 and Figure 18 , focusing on the differences between the first and second embodiments, the configuration and operation of the multi-winding motor drive control device according to the third embodiment will be described. exist Figure 12 to Figure 18 In the figure, the same code|symbol is attached|subjected to the part w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com