Manually assisted electric mulberry picker provided with rollers and sliders and used for diameter-changing branches

A technology of artificial assistance and picker, which is applied in the direction of picking machines, agricultural machinery and implements, etc. It can solve the problems of skin damage, surface oxidation, and low picking efficiency, and achieve easy cracking, thin peel, and good picking color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

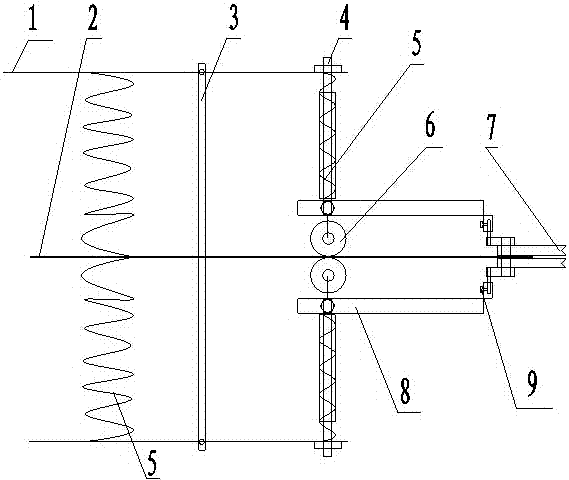

[0013] A roller slider type variable-diameter branch manual auxiliary electric mulberry picker, including a handle 1, a support rod 3, a spring 5, a picker and a collection bag, and a spring 5, a support rod 3 and a picker are fixedly installed on the handle 1, and the support Rod 3 is installed on the handle 1, and is hinged with handle 1, picker is made up of roller 6, telescopic rod 4, spring 5 and cutter 7 and collecting bag, and spring 5 is compression spring, and telescopic rod 4 one end is connected with roller 6, The other end passes through the through hole provided on the spring 5 and the handle 1 and is connected with the handle 1. One end of the connecting rod 8 is fixed on the telescopic rod 4 through a bolt 9, and the other end of the connecting rod 8 is connected with the connecting plate on the motor through a bolt 9. The blade of cutter 7 is a plurality of small circular arcs, close to the surface of mulberry branch 2, loosen bolt 9 to adjust the relative posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com