Solid phase microextraction device of echinoid fiber balls

An extraction device and fiber ball technology, applied in the field of solid-phase microextraction devices, can solve the problems of small surface area of the fiber head probe, consume manpower and material resources, increase the cost of use, etc., achieve uniform and stable sample concentration, shorten the analysis period, prolong the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

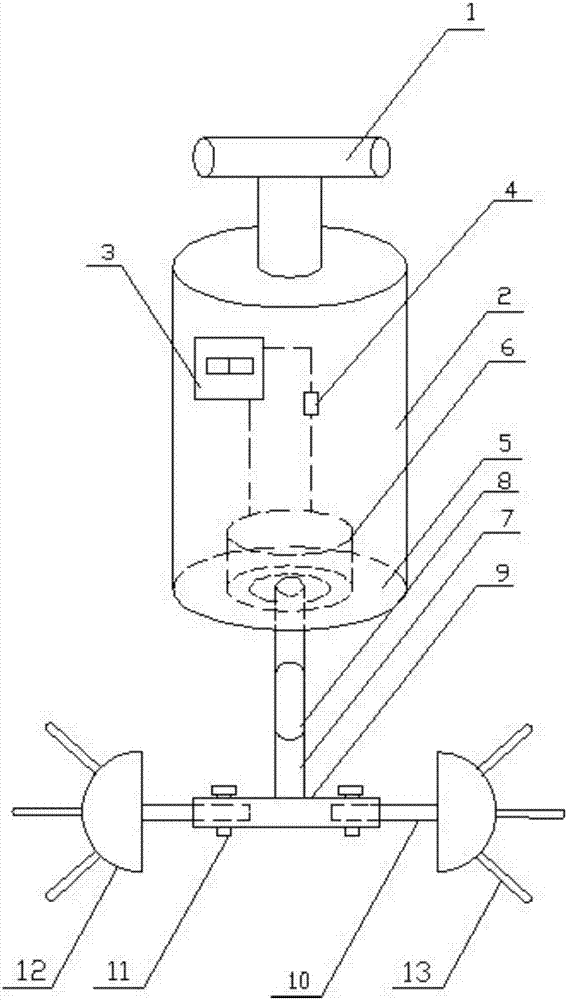

[0014] exist figure 1 In the schematic diagram of the present invention shown, the handle 1 is arranged on the upper part of the casing, the casing 2 is a cylindrical casing with a lower opening, and the timer 3 is embedded in the casing. A switch 4 is provided on the outer wall of the housing. The bottom of the shell is fixedly connected with the annular baffle 5, and the annular baffle is provided with a motor 6, and the motor, the timer and the switch are connected through wires. The output end of the motor is connected with the vertical rod 7 through a shaft coupling 8, and a hollow horizontal sleeve 9 is provided at the bottom of the vertical rod, and a through hole is provided on the horizontal sleeve, and the two sides of the hollow horizontal sleeve The ends are inserted into the horizontal rods 10 respectively, and through holes are provided on the two horizontal rods, and the positions of the through holes on the horizontal rods correspond to the positions of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com