Impurity removal device for removing impurities from large-capacity gas flow

A technology of gas flow and large volume, which is applied in the natural gas chemical industry and petroleum fields, can solve the problems of not being able to meet the requirements of large volume, and achieve the effects of simple structure, slow flow speed, resource recycling, energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

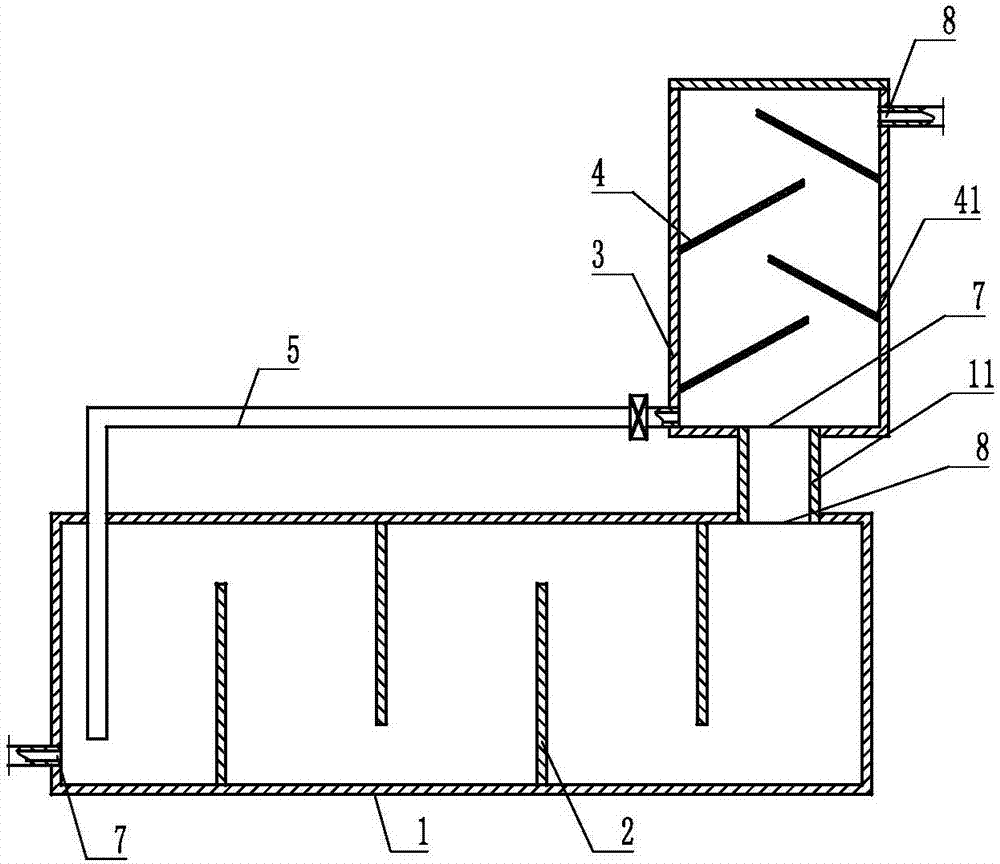

[0035] Embodiment 1: refer to figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, and is provided with a group of horizontal tank body 1 and a group of vertical tank body 3, and the horizontal tank body 1 and the vertical tank body 3 are all provided with an air inlet 7 and Gas outlet 8, a return pipe 5 and a connecting pipe 11 are arranged between the horizontal tank body 1 and the vertical tank body 3, one end of the connecting pipe 11 is connected to the gas outlet 8 of the horizontal tank body 1, and the other end is connected to the vertical tank body 1 The horizontal tank body 3 is connected to the air inlet 7, and the horizontal tank body 1 is provided with four barrier plates A2, the barrier plates A2 are straight, and the adjacent barrier plates A2 are in the horizontal tank body 1 Arranged in such a way that the free ends are staggered, several barrier plates B4 are provided on the inner wall of the vertical tank body 3, and the bar...

Embodiment 2

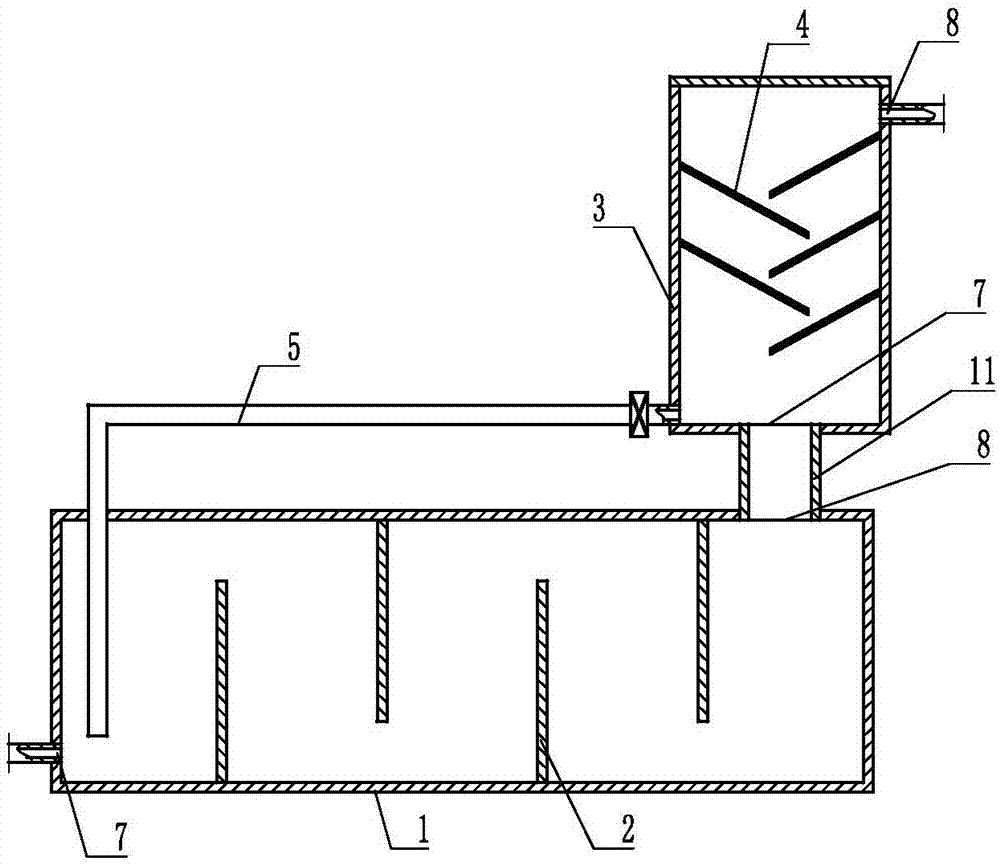

[0039] Embodiment 2: refer to figure 2 , is a schematic diagram of the structure of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the barrier plate B is arranged in the form of "\ / " on the inner wall of the vertical tank body 3.

Embodiment 3

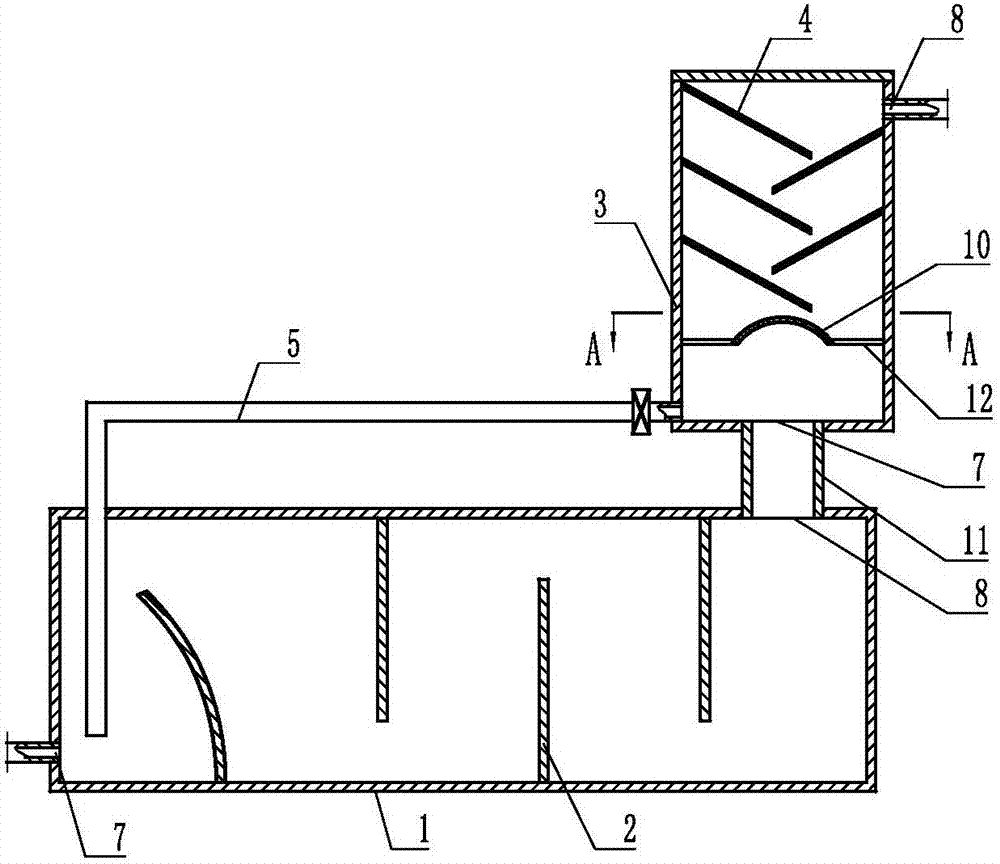

[0040] Embodiment 3: refer to Figure 3-4 , is a structural schematic diagram of Embodiment 3 of the present invention. Compared with Embodiments 1 and 2, the difference of this embodiment is that a baffle 10 is provided inside the vertical tank body 3, and the baffle 10 is arranged on the air intake Between the port 7 and the blocking plate B4, the baffle plate 10 is fixed on the inner wall of the vertical tank body 3 by a fixing rod 12 .

[0041] The barrier plate A2 is arranged in a mixed manner of arc shape and straight plate shape.

[0042] The gas is passed into the horizontal tank body 1 through the air inlet 7, the horizontal tank body 1 is provided with a liquid medicine, and the horizontal tank body 1 is provided with a barrier plate A2, and the upper and lower relative settings of the barrier plate A2 hinder The relative flow velocity of the liquid, when the gas is introduced from the air inlet 7, the liquid medicine will not be squeezed out from the air outlet 8 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com