Rhotanium nano rod with good near-infrared light absorption performance and photoelectrocatalysis performance and preparing method of rhotanium nano rod

A gold-palladium alloy and near-infrared light technology, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of difficult preparation of gold-palladium composite nanoparticles with optical properties, which do not show surface plasmons Resonant absorption characteristics and other issues, to achieve the effect of excellent near-infrared light absorption and photocatalytic performance, uniform size, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

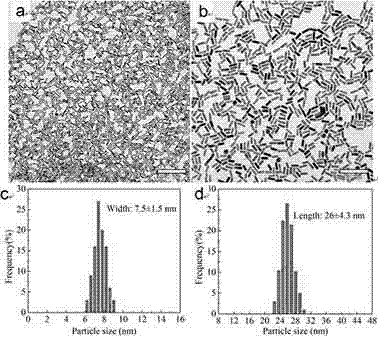

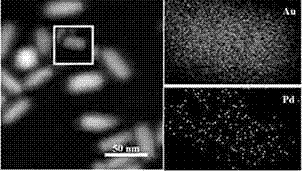

[0032] Preparation of 7.5×26 nm Au-Pd Alloy Nanorods

[0033] Add 9.1 ml of deionized water, 0.1 ml of 0.1 mol / L chloroauric acid, 0.1 ml of 0.1 mol / L sodium tetrachloropalladate, and 0.02 ml of 0.1 mol / L silver nitrate solution to 10 ml of 0.2 mol / L silver nitrate solution under stirring. liter of cetyltrimethylammonium bromide solution, stir well to obtain a yellowish brown solution, then add 0.2 ml of 1 mol / liter aqueous solution of hydroquinone, wherein cetyltrimethylammonium bromide, chloride The concentrations of gold acid, sodium tetrachloropalladate, silver nitrate, and hydroquinone are respectively 0.1 mol / liter, 0.0005 mol / liter, 0.0005 mol / liter, 0.0001 mol / liter, 0.01 mol / liter; When the color of the solution changes from yellowish brown to a colorless and clear solution, add 0.4 milliliters of prefabricated gold nanoparticle seed colloidal solution, and then react it in a 50 degree Celsius oven for 1 hour to obtain a green gold-palladium alloy nanorod colloidal so...

Embodiment 2

[0035] Preparation of gold-palladium alloy nanorods in different concentrations of cetyltrimethylammonium bromide solutions

[0036] Prepare 4 cetyltrimethylammonium bromide solutions with different concentrations and mark them as A, B, C, and D respectively. Add 14.1, 11.6, 6.6, and 4.1 ml of deionized water to (A) under stirring conditions. 5. (B) 7.5, (C) 12.5, (D) 15 milliliters of 0.2 mol / liter hexadecyltrimethylammonium bromide solution, then add 0.1 milliliter of 0.1 mol / liter chloroauric acid, 0.1 milliliter of 0.1 Mole / liter sodium tetrachloropalladate, 0.02 milliliter 0.1 mole / liter silver nitrate aqueous solution, stir evenly to obtain a yellow-brown solution, then add 0.2 milliliter 1 mole / liter hydroquinone aqueous solution, wherein, hexadecyltrimethyl The concentration of ammonium bromide is respectively (A) 0.05 mol / liter, (B) 0.075 mol / liter, (C) 0.125 mol / liter, (D) 0.15 mol / liter; among A-D, chloroauric acid and sodium tetrachloropalladate The concentrations...

Embodiment 3

[0038] Preparation of gold-palladium alloy nanorods under different conditions of chloroauric acid concentration

[0039] Add 36.4 ml of deionized water, 0.4 ml of 0.1 mol / L sodium tetrachloropalladate, and 0.08 ml of 0.1 mol / L silver nitrate aqueous solution to 40 ml of 0.2 mol / L hexadecyl trimethyl bromide In the ammonium solution, a brown solution was obtained after stirring evenly, wherein the concentrations of cetyltrimethylammonium bromide, sodium tetrachloropalladate, and silver nitrate were 0.1 mol / L, 0.0005 mol / L, and 0.0001 mol / L, respectively ; Divide the above prepared solution into 4 parts, marked as A, B, C, D respectively; then add different amounts of 0.1 mol / L chloroauric acid aqueous solution, wherein, (A) 0.04 ml, (B) 0.06 ml , (C) 0.08 ml, (D) 0.1 ml; then add 0.2 ml of 1 mol / L hydroquinone aqueous solution to A-D respectively; Add 0.4 ml of prefabricated gold nanoparticle seed colloid solution to A-D respectively, and then react it in an oven at 50 degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com