Automatic double-layer plate separator and working method thereof

A splitting machine, double-layer technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing labor intensity of operators, affecting operation efficiency, low milling precision, etc., and achieves a fixed effect Good, good protection effect, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings.

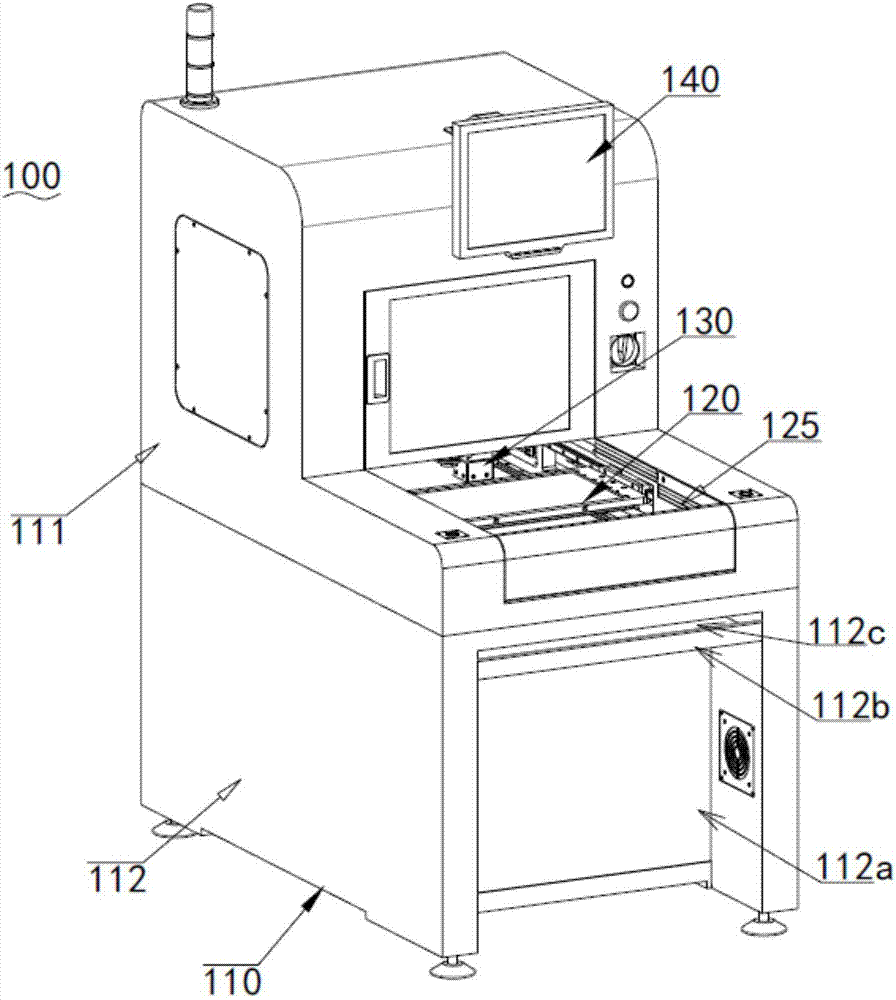

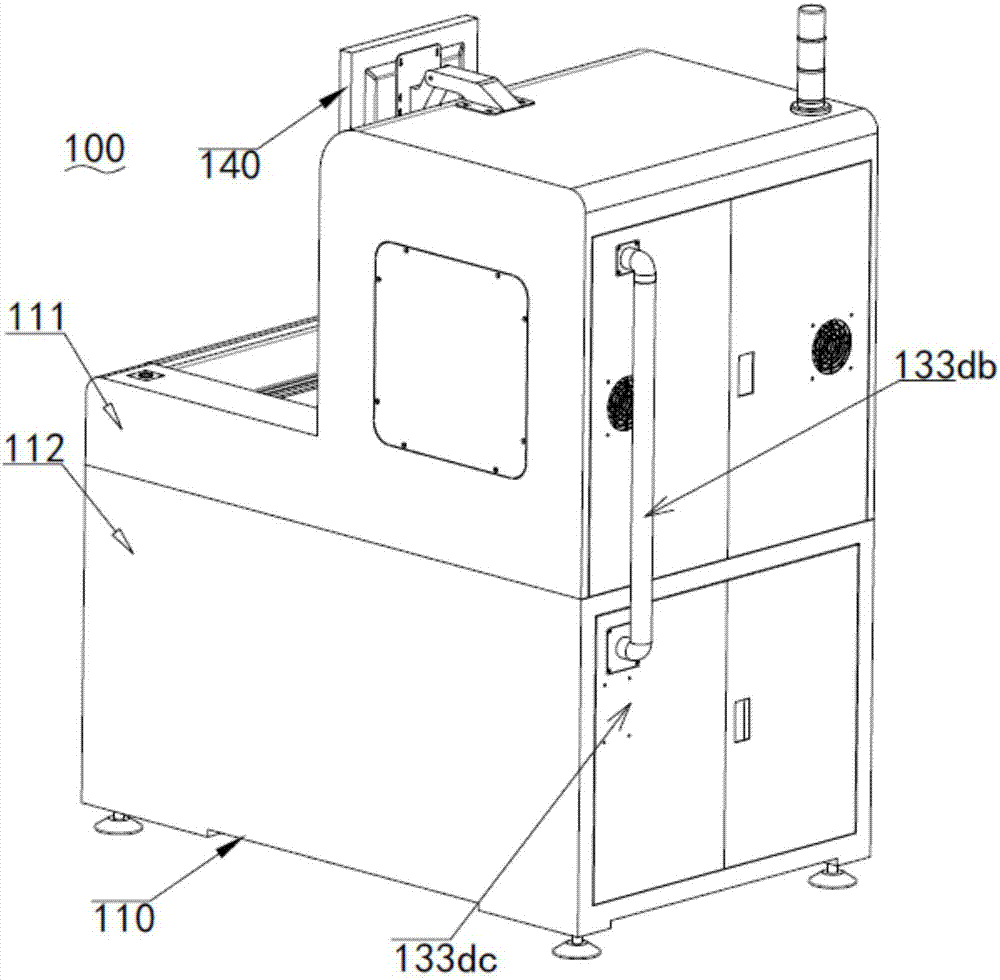

[0059] Such as Figure 1 ~ Figure 2 Shown are respectively the perspective views of different viewing angles of the present invention.

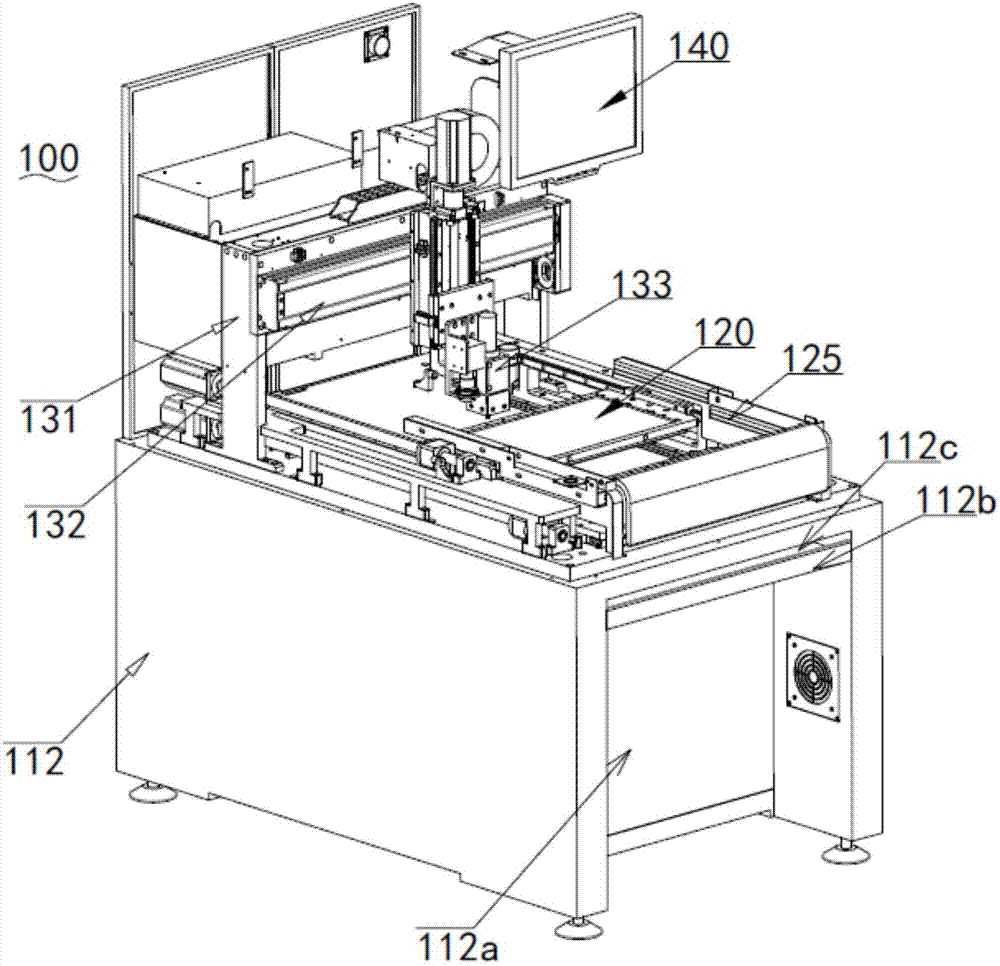

[0060] Such as image 3 Shown is a perspective view of the present invention with the upper frame removed.

[0061] A kind of double-deck automatic plate splitter 100, comprises frame 110, workbench 120, cutting device 130 and control device 140; Described frame 110 comprises upper frame body 111 and lower frame body 112, and described workbench 120 and cutting device 130 are installed on the lower frame body 112, the control device 140 is electrically connected with the workbench 120 and the cutting device 130, the control device 140 is installed on the upper frame body 111, and the upper frame body 111 is installed on the lower frame body 112 and is covered On the workbench 120 and the cutting device 130, the workbench 120 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com