Passive ultra-low energy consumption building roof lightning protection grounding installation clamp and use method

A lightning protection grounding and fixture installation technology, which is used in cable installation, ground connection, installation of lighting conductors, etc., can solve problems such as hidden dangers of quality, inability to weld, and hidden dangers of safety, so as to eliminate hidden dangers of safety and improve adjustment and adaptability. , to ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

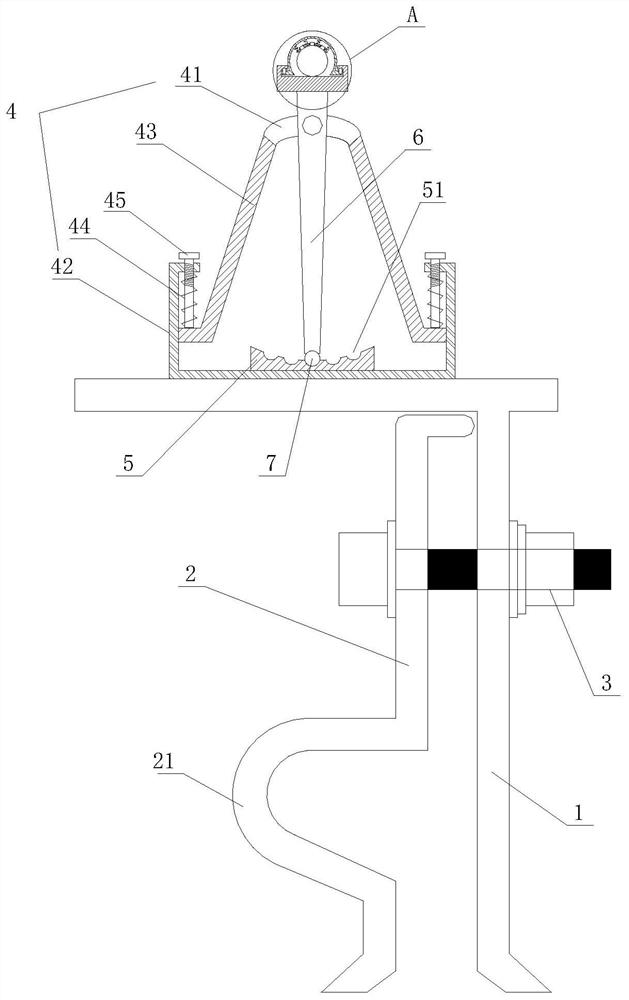

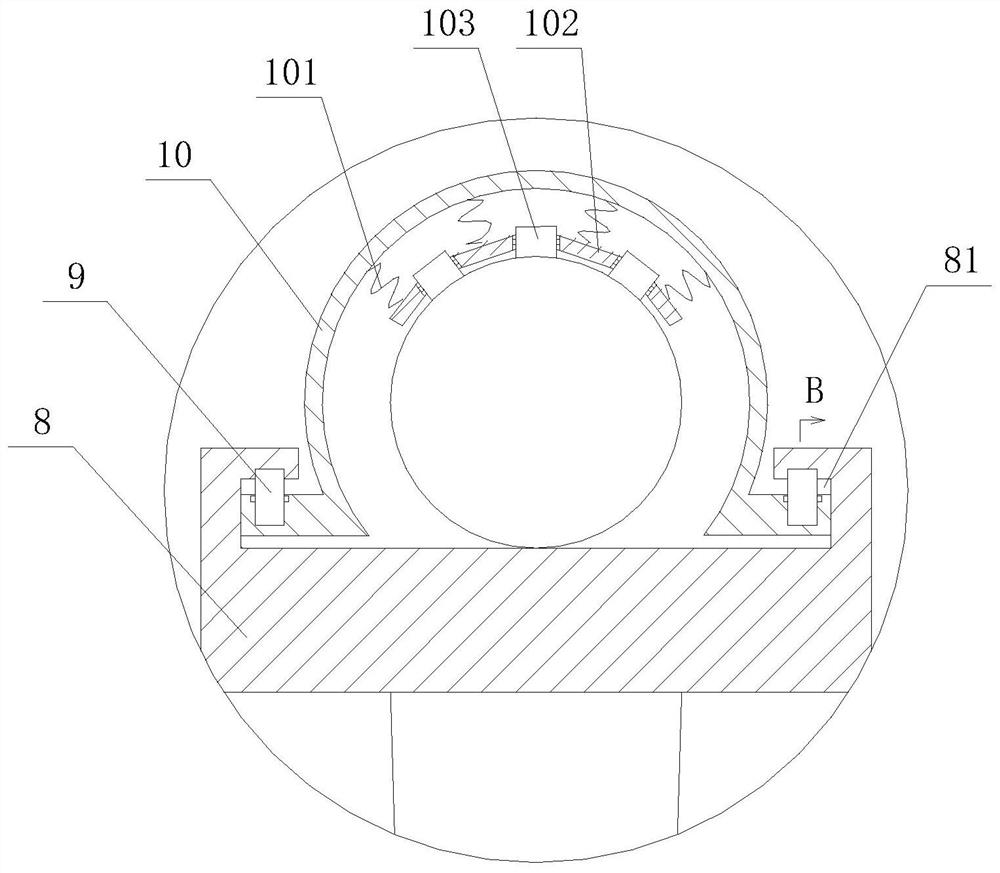

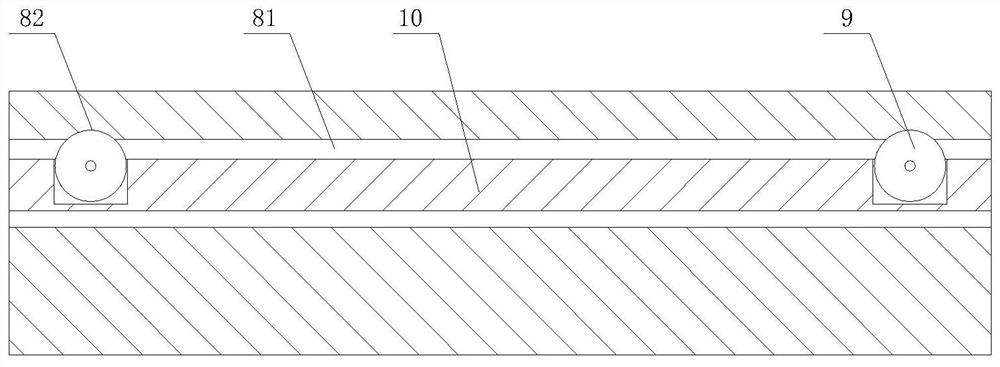

[0035] Such as Figure 1 to Figure 3 As shown, the installation fixture for lightning protection grounding on the roof of passive ultra-low energy buildings includes:

[0036] Clamping assembly. The clamping assembly includes a fixed part 1, a moving part 2 and an adjusting part 3. The fixing part 1 is connected to the moving part 2 through the adjusting part 3 for connection with the roof. Specifically, the fixing part 1 is in the shape of a "T" Structure, the side of the moving part 2 opposite to the fixed part 1 is provided with a positioning part 21 adapted to the roof structure, and the adjusting part 3 is an adjusting bolt. The fixed part 1 and the moving part 2 are connected as a whole through the adjusting part 3, and the adjusting part 3 is continued to be adjusted so that the moving part 2 continues to move to the side close to the fixed part 1, and finally the roof is clamped to achieve a fixed installation effect that the fixture does not damage the roof as a whole...

Embodiment 2

[0046] The method of using the installation fixture for lightning protection and grounding of the roof of a passive ultra-low energy building includes the following steps:

[0047] A. First connect the fixed part 1 and the moving part 2 through the adjusting part 3, and adjust the adjusting part 3 to move the moving part 2 to the side close to the fixed part 1 until the positioning part 21 on the moving part 2 is suitable for the longitudinal seam of the roof. Matching, to achieve the effect of the overall fixed installation of the fixture;

[0048] B. According to the installation position of the lightning protection belt, first pull the connecting piece 8 so that the support rod 6, the positioning block 7, and the moving part 43 move up at the same time, and the positioning block 7 is separated from the positioning groove 151, and then adjust the connecting piece 8 and the moving part 43 There is a suitable angle between them, which is the best connection angle. After the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com