Slide block plunger biomass forming machine

A biomass molding machine, plunger type technology, applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of pressure rollers and molding die wear, to reduce friction, simple and convenient operation, extrusion stressful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are preferred embodiments of the present invention, but the protection scope of the present invention is not limited thereby.

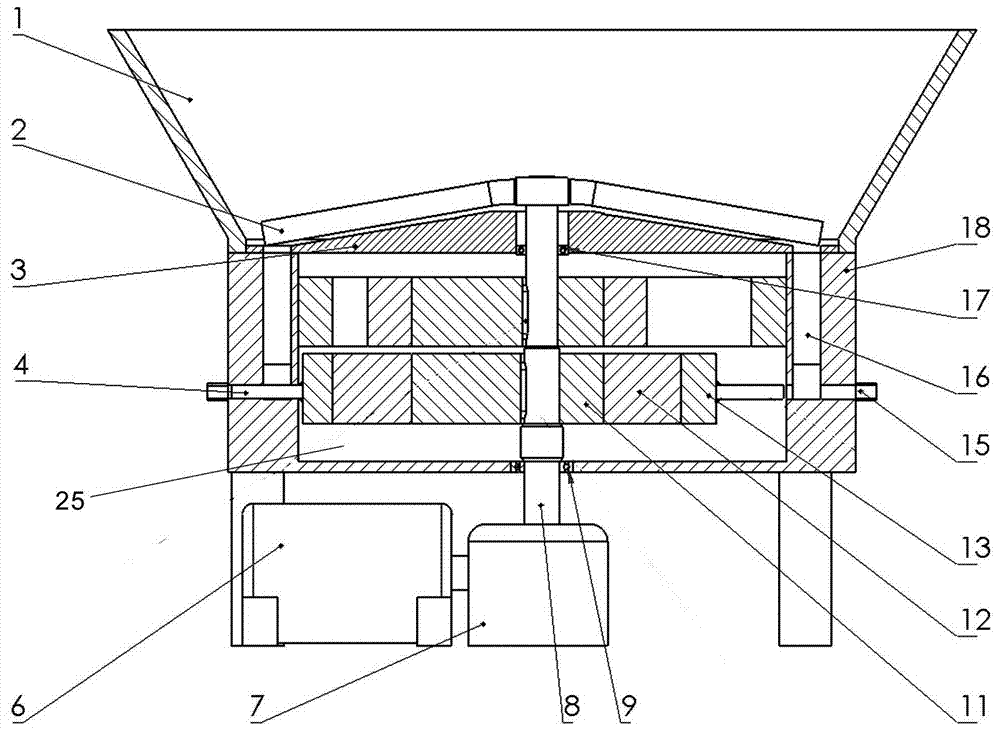

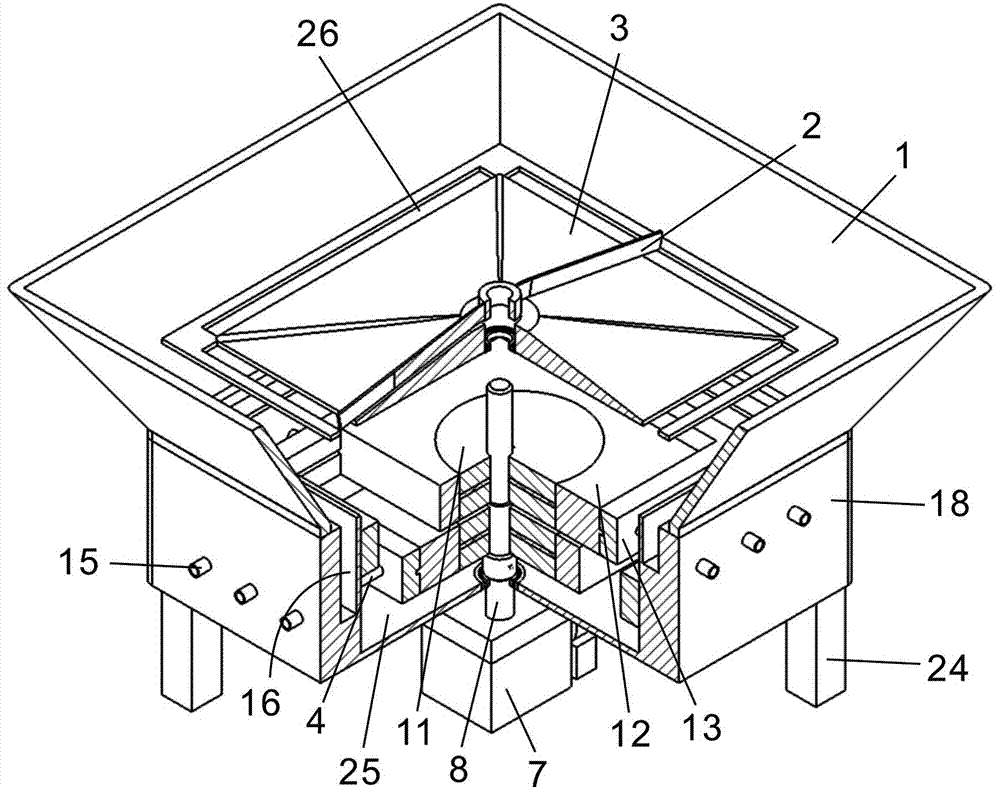

[0019] As shown in the figure, a slider plunger type biomass molding machine includes a fixing device, a punching device and a driving device, wherein the punching device is installed in the fixing device, and the driving device drives the movement of the punching device and completes the pressing of the product.

[0020] The fixing device mainly includes a frame 24 and a fixed square base 18 above the frame 24, wherein a cabin 25 with an open top is provided in the middle of the square base 18, and a groove 16 is provided on the top of the square base 18 at the periphery of the cabin 25. edge, and the molding die 15 communicating with the groove 16 is installed on the outside of the square base 18, and the side wall of the nacelle 25 is provided with a plunger hole coaxial with the molding die 15; Next to the fixed cover 3 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com