A hydraulic rotary shoe guide

A hydraulic rotation and shoe-guiding technology, which is applied in the direction of drill pipe, casing, wellbore/well parts, etc., can solve the problems of high casing friction resistance, affecting casing running speed, and single function, so as to reduce friction The effect of resisting and improving chip carrying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

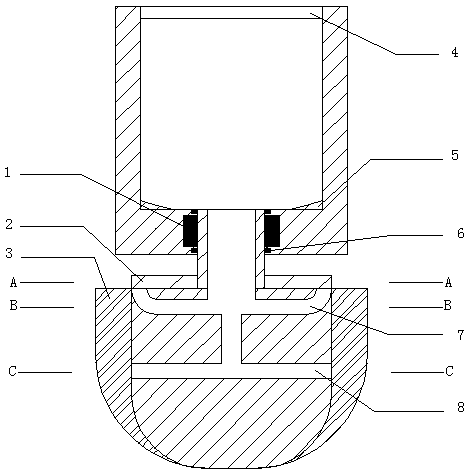

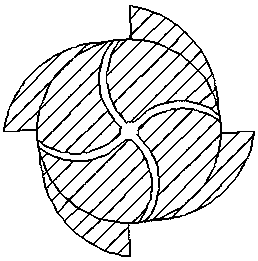

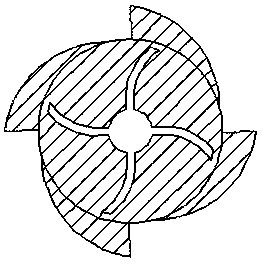

[0023] see figure 1 , figure 2 , image 3 , Figure 4 .

[0024] A hydraulic rotary guide shoe is composed of a casing joint, a rotating body and a tapered bearing 1. The casing joint is a hollow cylindrical barrel with an outer diameter slightly larger than the outer diameter of the casing. There is a drilling fluid channel in the lower part, an internal thread 4 at the top, and a reinforcing point 5 at the bottom; the casing joint and the rotating body Connected by a conical bearing 1, the conical bearing is embedded in the bottom of the cylindrical barrel through a sealing ring 6; the rotating body is a hemispherical body with a diameter slightly larger than the outer diameter of the casing, and the drilling fluid channel on the upper part is connected to the drilling fluid channel on the lower part of the casing joint Connected, with a spiral blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com