Dissolvable bridge plug and bridge plug fracturing system

A technology of bridge plugs and components, applied in the field of dissolvable bridge plugs and bridge plug fracturing systems, which can solve the problems of difficult operation of drilling plugs and drilling debris affecting normal operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

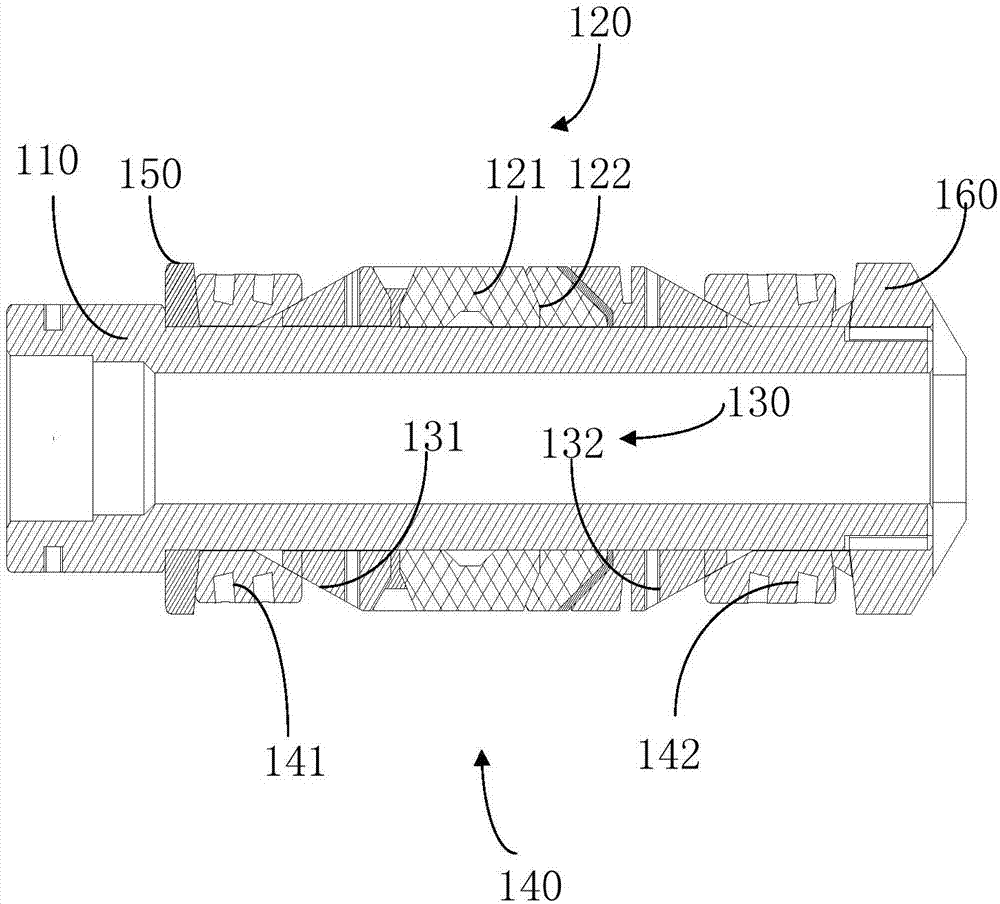

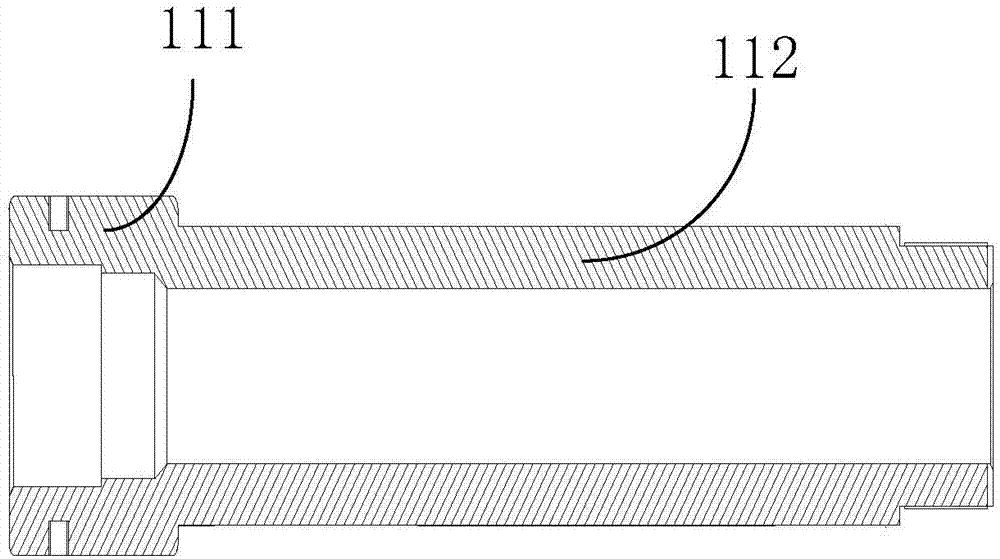

[0057] This embodiment provides a dissolvable bridge plug 100, please refer to Figure 1 to Figure 3 ,include:

[0058] The central pipe 110 has a central flow channel, and the connecting end is used for connecting the setting tool 400;

[0059] The rubber cartridge assembly 120 is set on the central tube 110 and is used for radially positioning the bridge plug 100 in the extrusion state;

[0060] The vertebral body assembly 130 is sleeved on the central tube 110 and located on both sides of the rubber tube assembly 120, for applying a relative extrusion force to the rubber tube assembly 120 along the axial direction of the central tube 110;

[0061] The slip assembly 140 is sleeved on the central tube 110 and located on both sides of the vertebral body assembly 130 away from the rubber barrel assembly 120 , for axially positioning the bridge plug 100 and for driving the vertebral body assembly 130 to move toward the rubber barrel assembly 120 ;

[0062] The push ring 150 is...

Embodiment 2

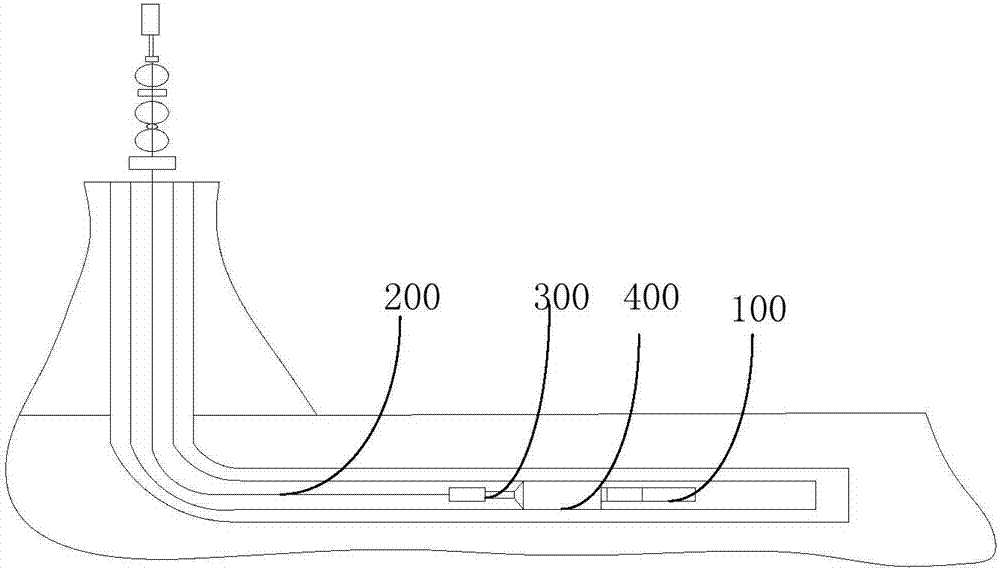

[0101] This embodiment provides a pumping bridge plug 100 fracturing system, please refer to image 3 , including the dissolvable bridge plug 100 in Example 1. It also includes: a perforating gun, a setting tool 400, a cable joint 300, a cable 200, and the like.

[0102] Using the pumping bridge plug 100 fracturing system provided in this embodiment, since the bridge plug 100 can achieve precise axial and radial positioning, and each part of the bridge plug 100 can be effectively dissolved, it can effectively avoid the There are difficulties in the drilling operation of the bridge plug 100 and the problems of drilling debris.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com