Resin and mortar combined anchor rod supporting structure and construction method thereof

A technology of bolt support and resin mortar, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of high cost, low cost, slow force, etc., and achieve strong applicability and strong pull-out resistance , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

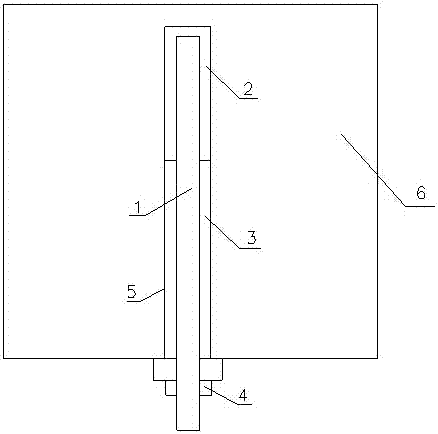

[0017] refer to figure 1 , the resin mortar combined bolt support structure of the present embodiment comprises a surrounding rock 6, and a borehole 5 is arranged in the surrounding rock 6, and an anchor rod body 1 is arranged in the borehole 5, and the anchor rod body 1 is a threaded steel anchor rod body , the upper part of the bolt body 1 in the borehole 5 is filled with resin anchoring agent 2 to form a resin anchoring section; the middle and lower sections are filled with mortar anchoring agent 3 to form a mortar anchoring section; The pre-tightening and slurry stop device 4 is locked.

[0018] The length of the resin anchoring section is determined by calculating the actual required temporary support strength. In this embodiment, the length of the resin anchoring section is 0.8m.

[0019] The length of the mortar anchoring section is determined by calculating the actual required permanent support strength. In this embodiment, the length of the mortar anchoring section i...

Embodiment 2

[0026] The construction method of the resin mortar combined bolt support structure of the present embodiment comprises the following steps:

[0027] (1) Drill holes 5 in the surrounding rock 6 of the roadway or tunnel, and clean the holes;

[0028] (2) Use grouting equipment to fill the mortar anchoring agent 3 from the bottom of the hole 5 to the outside; use the anchor rod body 1 to insert the resin roll into the drill hole 5 and screw it to the bottom of the hole, and rotate the anchor rod body 1 to make the bottom of the hole The resin anchoring agent 2 in the resin roll is completely overflowed; in this embodiment, the resin roll is an epoxy resin roll with a diameter of 28 mm and a length of 0.4 m per roll, and 2 rolls are used for each hole;

[0029] (3) After the resin anchoring agent is solidified, install the pre-tightening and slurry stop device 4 of the orifice. After the resin anchoring agent 2 is solidified, the upper section of the anchor rod body 1 is anchored ...

Embodiment 3

[0032] The construction method of the resin-mortar combined bolt support structure of this embodiment differs from that of Embodiment 1 only in that rapid hardening cement is used instead of resin anchoring agent 3, and the rest is the same as that of Embodiment 1.

[0033] The present invention integrates the advantages of fast stress on the resin anchor and strong applicability of the full anchor of the mortar anchor, and can provide temporary support and permanent support. The temporary end anchor is combined with the permanent full anchor. The resin anchorage section and the mortar anchorage section provide permanent support together, and the pullout resistance provided by the resin anchorage section of the present invention, that is, the temporary support strength provided by the resin anchorage section, should be greater than the actual required temporary support strength; the resin anchorage section and the mortar anchorage The total pull-out force provided by the sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com