Heat pipe natural cooling evaporative-type condensation water chiller and control method thereof

An evaporative condensation and natural cooling technology, which is applied to the control input related to air characteristics, space heating and ventilation control input, heating methods, etc., can solve the problems of increased investment, general antifreeze effect, corrosion of pipelines and equipment, etc. , to achieve the effect of reducing energy consumption, avoiding insufficient liquid supply and frequent start and stop of compressors, and improving energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

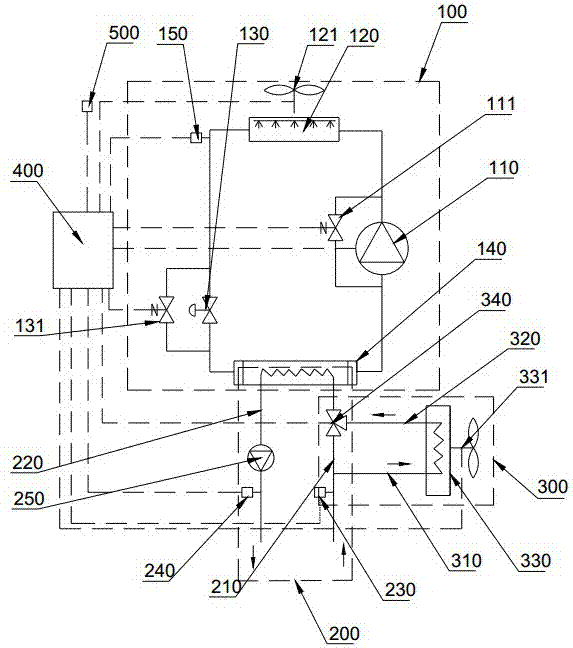

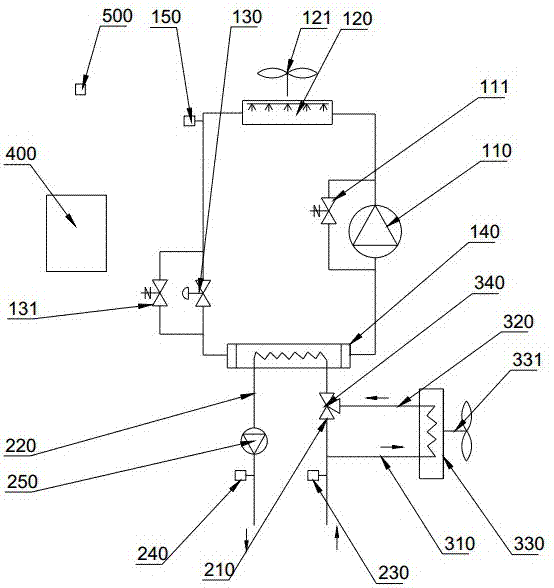

[0027] A heat pipe natural cooling evaporative condensation chiller, comprising a mechanical refrigeration system 100 composed of a compressor 110, an evaporative condenser 120, a throttle 130, and an evaporator 140, the evaporative condenser 120 is provided with a condensing fan 121, A condensation pressure sensor 150 is provided on the pipeline of the mechanical refrigeration system 100 . Also includes a secondary circulation system 200 for heat exchange with the evaporator 140, the secondary circulation system 200 is provided with a natural cooling system 300 that can control the flow of water in the secondary circulation system to exchange heat with water; The throttle 130 of the mechanical refrigeration system 1 is connected in parallel with a throttle bypass solenoid valve 131, and its compressor 110 is connected in parallel with a compressor bypass solenoid valve 111; the mechanical refrigeration system 100, the secondary circulation system 200 and the natural cooling sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com