Experimental system for analyzing dynamic scaling trend of geothermal water

A technology of trend analysis and experimental system, applied in the direction of testing water, material inspection products, etc., can solve the problems of high experimental cost and poor system applicability, and achieve the effect of convenient experimental research, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

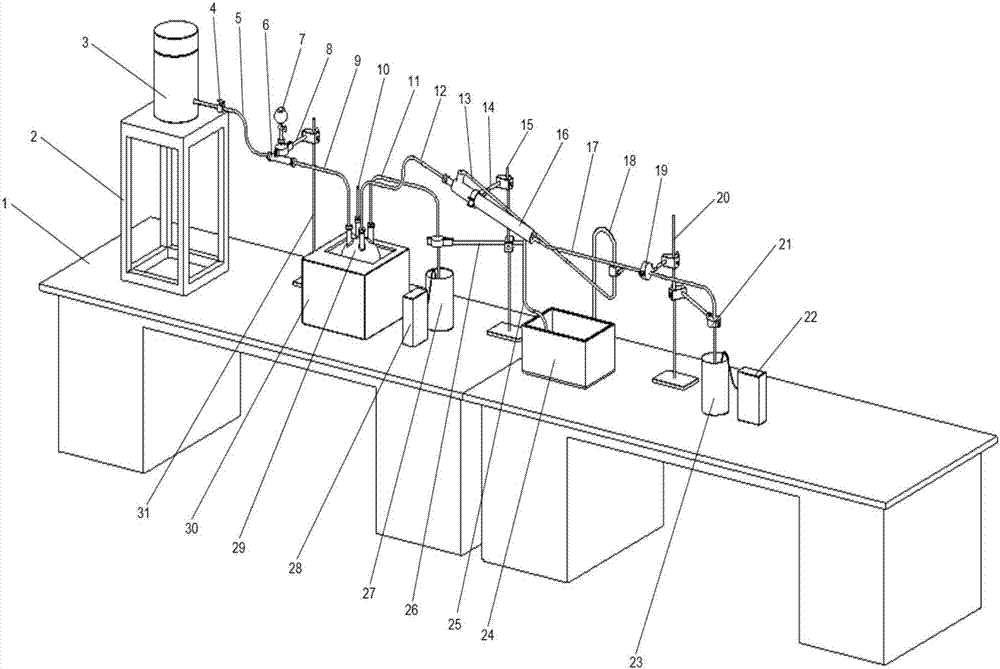

[0019] refer to Figure 1 to Figure 3 , The present invention is an experimental system for dynamic scaling trend analysis of geothermal water, which is composed of an auxiliary system, a visualization system, a detection system, a storage system and a heating system.

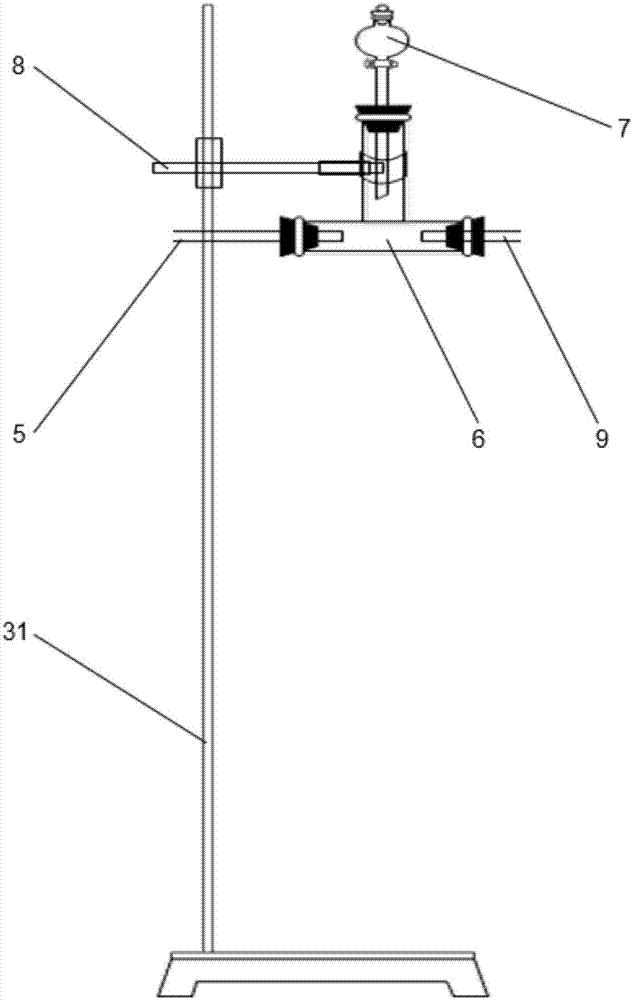

[0020] The auxiliary system consists of test bench (1), bracket (2), iron stand I (15), iron stand II (20), iron stand III (31), flask clamp I (8), flask clamp II (14), flask Clamp III (19), flask clamp IV (21), flask clamp V (26) and condensate pipe (18), the bracket (2) is used to support the water storage bucket (3), and the iron stand III (31) is used to fix the three Pass (6), iron stand I (15) is used to fix the condensation pipe (16) and conduit III (11), iron stand II (20) is used to fix the conduit VI (17), each part is built on the test bench (1) above, constitute the whole experimental system.

[0021] The visualization system consists of valve (4), conduit I (5), conduit II (9), conduit III (11), ...

Embodiment

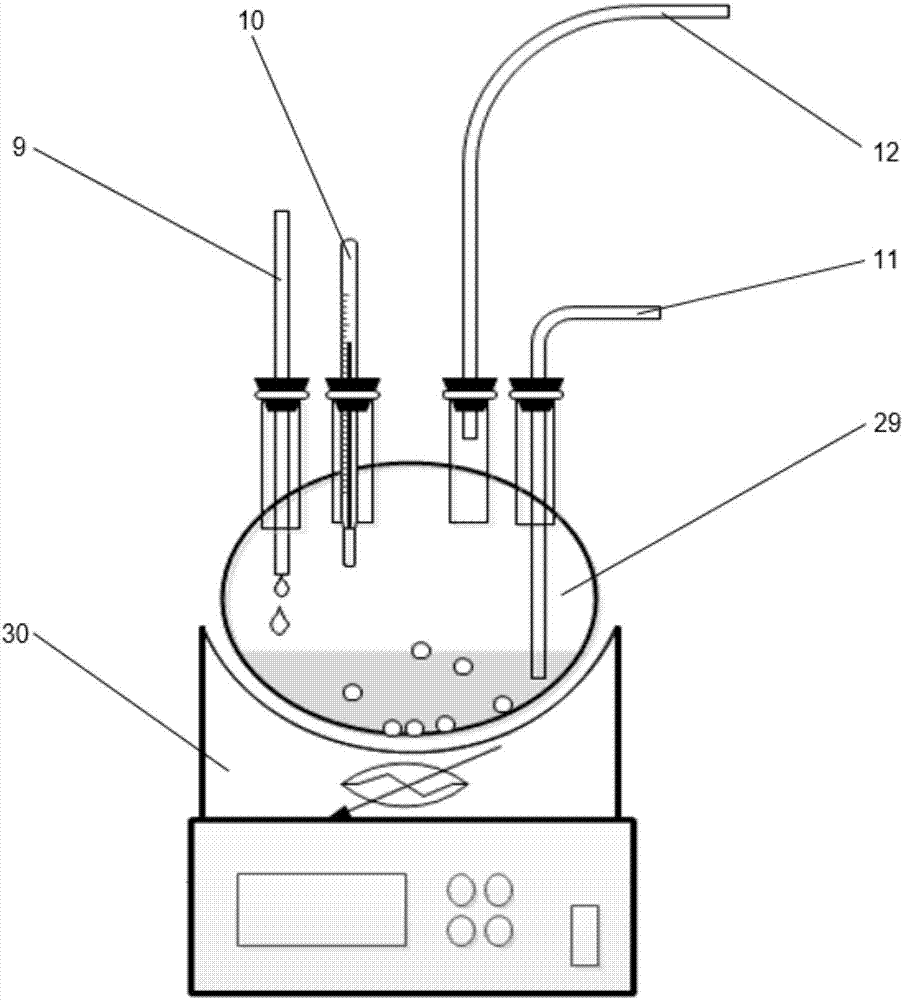

[0027] like Figure 1 to Figure 3 As shown, the bracket (2) is placed on the test bench (1), the water storage bucket (3) is placed on the bracket (2), and the water storage bucket (3) and the tee (6) are connected through the conduit I (5). Use the iron stand III (31) and the flask clamp I (8) to fix the tee (6), place the dropping funnel (7) on the tee (6), and use the dropping funnel (7) to drop various additives; Connect the tee (6) to a bottle mouth on the four-necked flask (29) through the conduit II (9), and the thermometer (10) is placed in a bottle mouth on the four-necked flask (29), and use the conduit IV ( 12) Lead sampled water from a bottle mouth on the four-neck flask (29) to the beaker II (27), use the scale ion detector II (28) to measure the concentration of scale ions in the water, and use the iron stand I (15 ) and flask clamp V (26) to fix the conduit III (11), and the four-necked flask (29) utilizes a magnetic stirring electric heater (30) to heat; conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com