Method for segmented manufacturing of super-large aperture Fresnel lens

A Fresnel lens and ultra-large-diameter technology, which is applied in the field of segmented production of super-large-diameter Fresnel lenses, can solve the problems of huge manufacturing costs, limited size of Fresnel lenses, and inability to manufacture large sizes, so as to achieve diversified applications, The effect of guaranteeing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

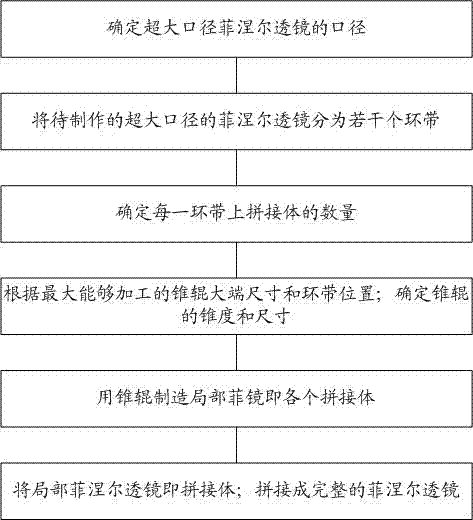

Method used

Image

Examples

Embodiment 1

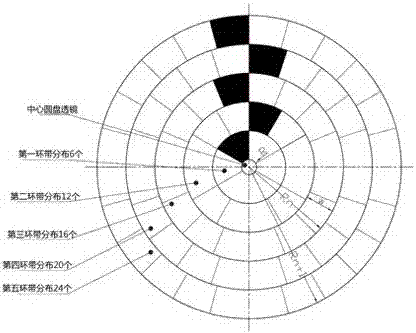

[0041] Example 1 Design and manufacture of a 20-meter-diameter spliced Filipino mirror:

[0042] The center of the Philippine mirror is a complete circular Philippine mirror. The selected radius of the design is 500 mm, that is, the diameter is 1 meter; it can also be manufactured by splicing. The other parts of the Philippine mirror are spliced by multiple pieces, and the spliced Philippine mirror is composed of multiple ring belts and multiple splicing bodies in the ring belt. Each splice has the same optical parameters or different optical parameters, and the same size or different sizes.

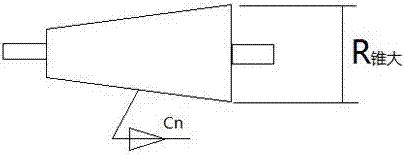

[0043] The width of each annular belt and the quantity and size of splices in the annular belt are designed according to the principle of being conducive to manufacture. In this example, a ring of equal width is used, and the width of the ring is 1900mm according to the equipment opening that can process a tapered Fresnel lens; rings of unequal width can also be used.

[0044] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com