Engraving machine

A technology of engraving machine and frame, which is applied in the field of engraving machines, can solve the problems of reduced precision and achieve the effect of improving precision and strengthening structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

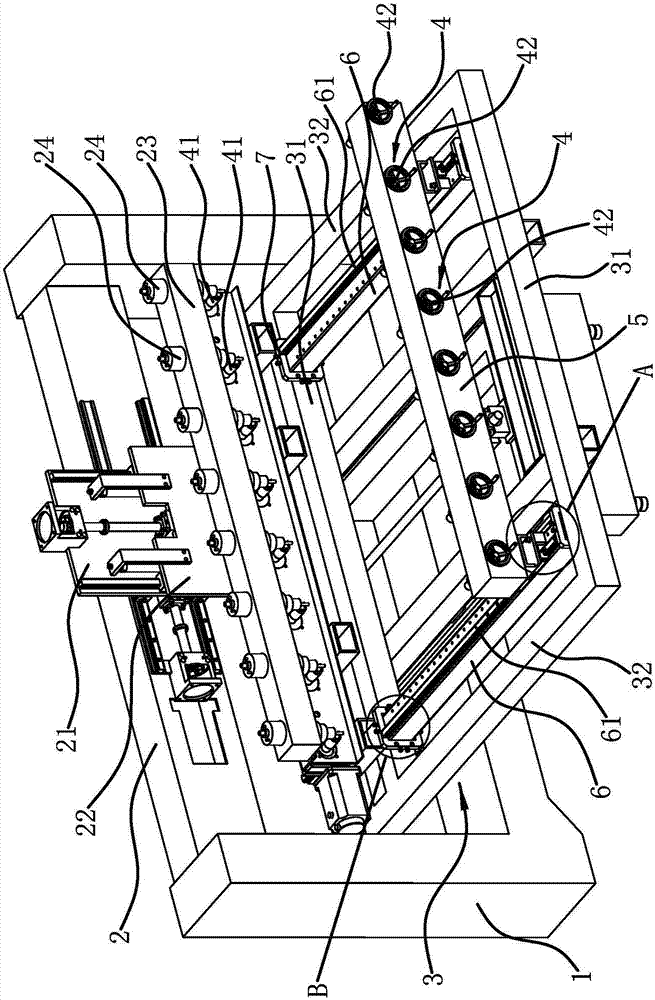

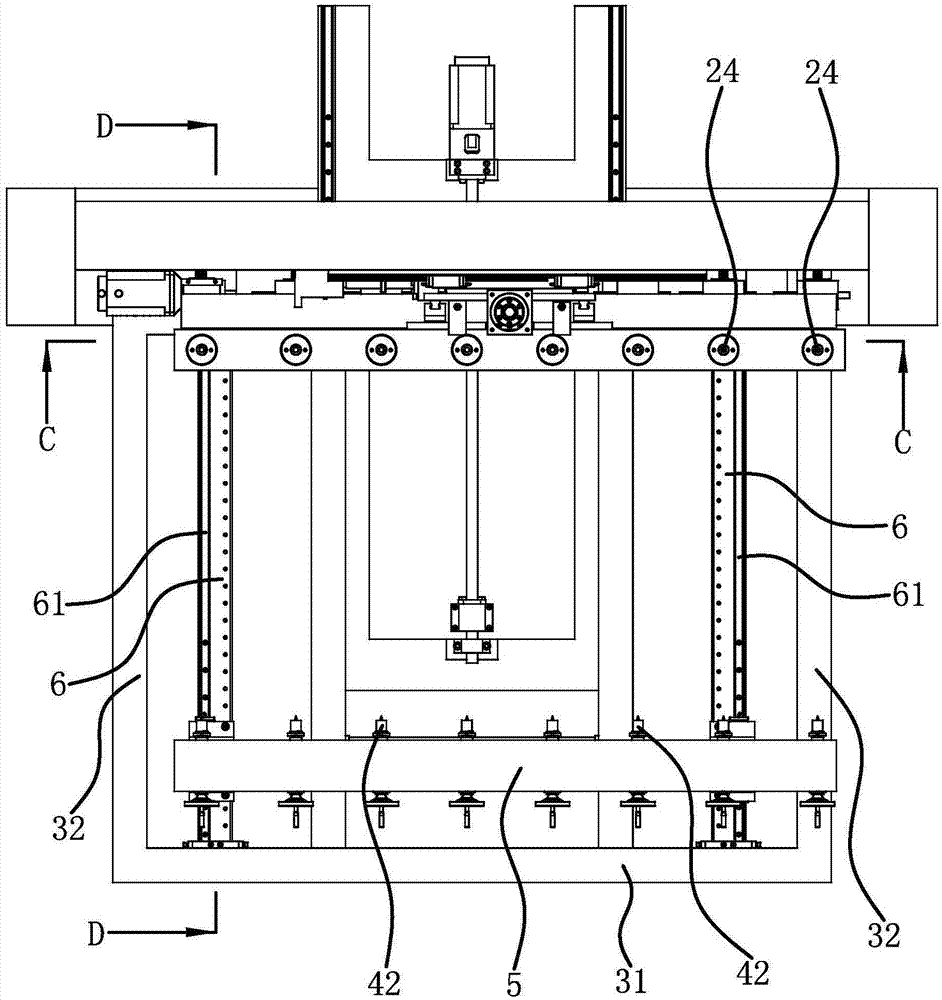

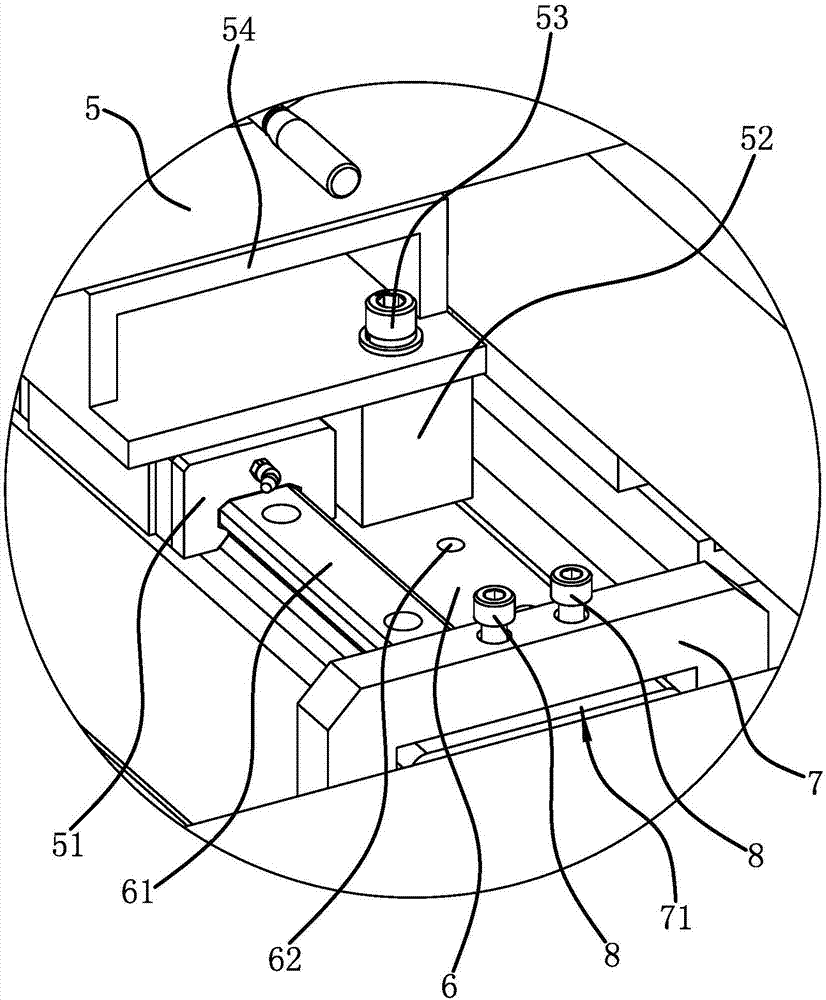

[0034] like figure 1 As shown, a kind of engraving machine comprises frame 1, and the width direction of frame 1 is transverse, is fixedly connected with crossbeam 2 on frame 1, and this crossbeam 2 is arranged along the width direction of frame 1, on crossbeam 2 along the transverse direction Slidingly connected with a horizontal supporting plate 21, the horizontal supporting plate 21 is vertically slidably connected with a vertical supporting plate 22, and the vertical supporting plate 22 is fixedly connected with a tool holder 23. A plurality of downward carving cutter heads 24 are connected along the length direction. to combine figure 2 As shown, the frame 1 is also slidably connected with a working platform 3, the working platform 3 is located below the tool holder 23, and the working platform 3 can move along the front and rear directions of the frame 1, and the working platform 3 becomes a rectangular frame shape. 3 is provided with two supporting beams 6 and a posi...

Embodiment 2

[0037] The structure of the engraving machine is basically the same as that of Embodiment 1, the difference is that Figure 9 As shown, the support body 7 includes four support blocks 73, and the four support blocks 73 are all fixed on the inner side of the working platform 3 by screws, wherein two support blocks 73 are distributed along the lateral direction, and the other two support blocks 73 are vertically distributed. Distributed, the area in the middle of the four support blocks 73 forms the socket 71, and each support block 73 is screwed with two fixing bolts 8.

Embodiment 3

[0039] The structure of the engraving machine is basically the same as that of Embodiment 1, the difference is that Figure 10 As shown, the support beam is made into a cylindrical guide rail 10, and a rectangular block-shaped connection seat 9 is fixed at the end of the cylindrical guide rail 10. The connection seat 9 is inserted into the support body 7, and the fixing bolt 8 is locked against the On the outer surface of the connecting seat 9, when the cylindrical guide rail 10 of this structure is adopted, the positioning beam 5 is slidably connected on the cylindrical guide rail 10 through the guide sleeve, that is, the lower side of the positioning beam 5 two ends is fixed with an adjustment spacer 54, and when adjusting The lower side of the cushion block 54 is fixedly connected with a guide sleeve, and the guide sleeve is slidably sleeved on the cylindrical guide rail 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com