A kind of synthetic method of sulfur-containing silane

A synthesis method and technology of sulfur silane, applied in the field of synthesis of sulfur-containing silane, can solve the problems of low product yield, unstable quality, and high cost of environmental protection treatment, and achieve the effects of improving reaction, ensuring quality and good appearance characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

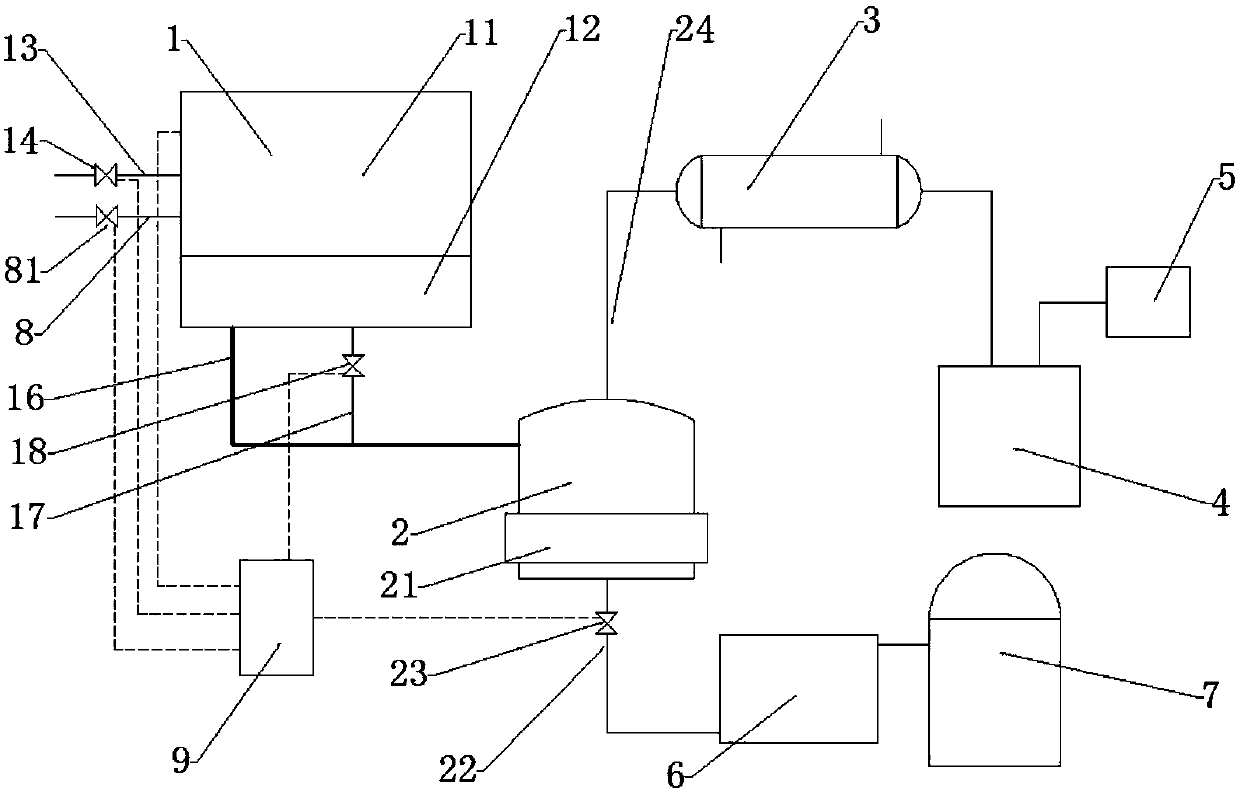

Method used

Image

Examples

preparation example Construction

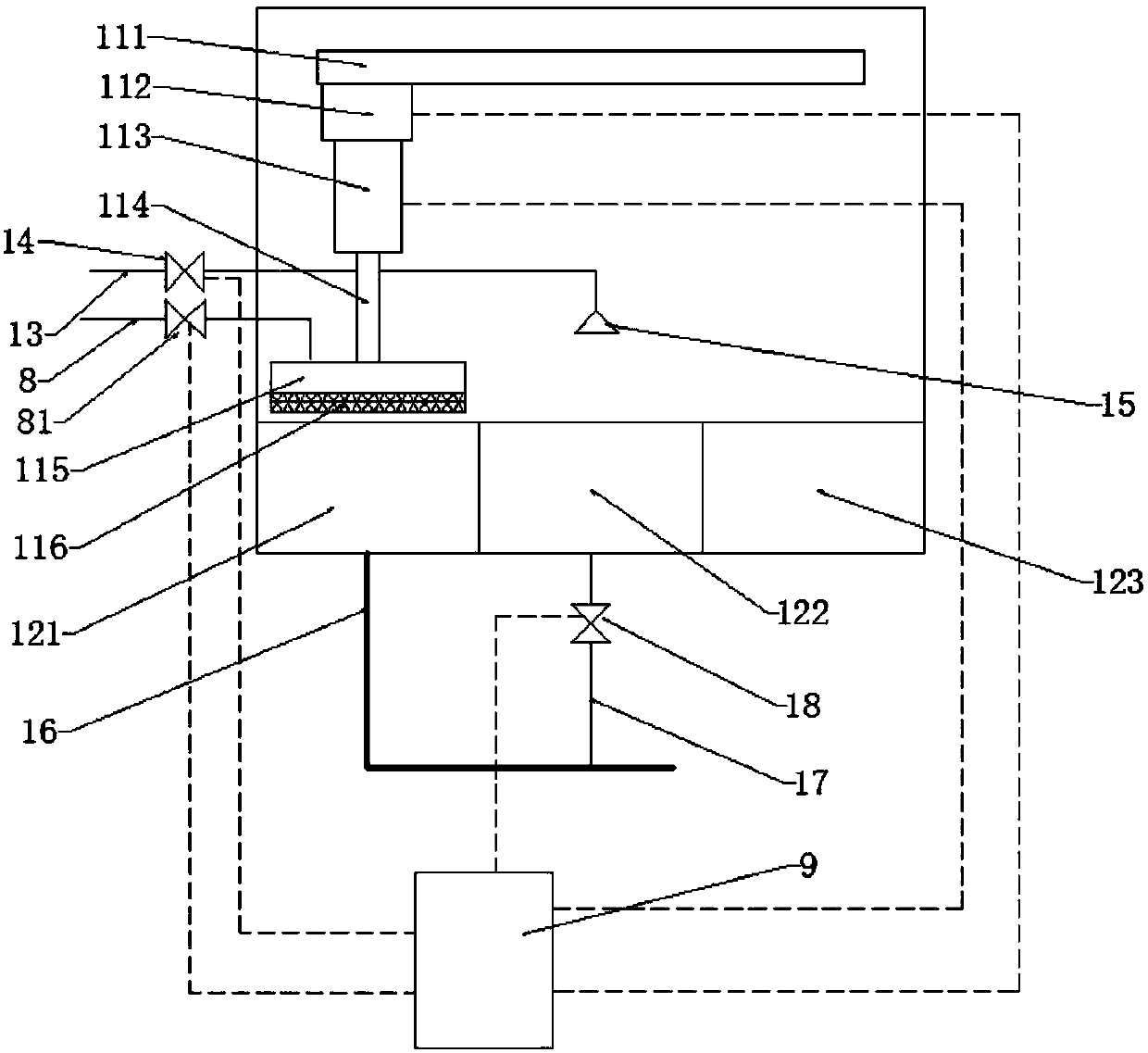

[0064] A method for synthesizing sulfur-containing silanes, using one or more of dimethylformamide, dimethylacetamide, hexamethylphosphoramide, and 1,3-dimethyl-2-imidazolidinone as a solvent, Do the following steps:

[0065] S1. Under nitrogen protection, put sodium metal and the solvent into a metering tank, heat to 98-120°C, disperse, and prepare a sodium suspension;

[0066] S2. Under nitrogen protection, put sulfur and the solvent into a stirred tank, heat to 113-120°C, disperse, and prepare a sulfur suspension;

[0067] S3. Under the protection of nitrogen, the temperature of the sulfur suspension is controlled at 45-100° C., and the sodium suspension prepared in step S1 is added dropwise into the sulfur suspension. After the addition is completed, the temperature is maintained and the reaction is continued for 5-15 minutes. Obtain the organic solution of sodium polysulfide;

[0068] S4. Under nitrogen protection and stirring, control the temperature of the organic sol...

Embodiment 1

[0120] Use molecular sieves to dehydrate the dimethylformamide solvent, then pass nitrogen gas into the dimethylformamide solvent under a pressure of 0.04Mpa and ultrasonically treat it for 5 minutes, and the dissolved oxygen in the dimethylformamide solvent is measured to be less than 3ppm , and then proceed as follows:

[0121] S1. Under nitrogen protection, put sodium metal and dimethylformamide solvent into a metering tank, heat to 100°C, and disperse to prepare a sodium suspension with a sodium concentration of 4mol / L;

[0122]S2. Under nitrogen protection, put sulfur and dimethylformamide solvent into a stirred tank, heat to 115°C, and disperse to prepare a sulfur suspension with a sulfur concentration of 4mol / L;

[0123] S3. Under the protection of nitrogen, the temperature of the sulfur suspension is controlled at 60° C., and the sodium suspension prepared in step S1 is added dropwise to the sulfur suspension, and the volume ratio of the sodium suspension to the sulfur...

Embodiment 2

[0127] Use calcium sulfate and magnesium sulfate to dehydrate the dimethylacetamide solvent, then under the pressure of 0.015Mpa, feed nitrogen into the dimethylacetamide solvent and ultrasonically treat it for 3min, measure the Dissolved oxygen is less than 3ppm, then proceed to the following steps:

[0128] S1. Under nitrogen protection, put sodium metal and dimethylacetamide solvent into a metering tank, heat to 98°C, and disperse to prepare a sodium suspension with a sodium concentration of 2mol / L;

[0129] S2. Under nitrogen protection, put sulfur and dimethylacetamide solvent into a stirred tank, heat to 120°C, and disperse to prepare a sulfur suspension with a sulfur concentration of 8mol / L;

[0130] S3, under the protection of nitrogen, the temperature of the sulfur suspension is controlled at 100°C, the sodium suspension prepared in step S1 is added dropwise into the sulfur suspension, the volume ratio of the sodium suspension to the sulfur suspension is 1:1, Add dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com