Boron-molybdenum integrated lubricating oil additive, preparation method and applications thereof

A technology of lubricating oil additives and additives, applied in the directions of additives, lubricating compositions, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

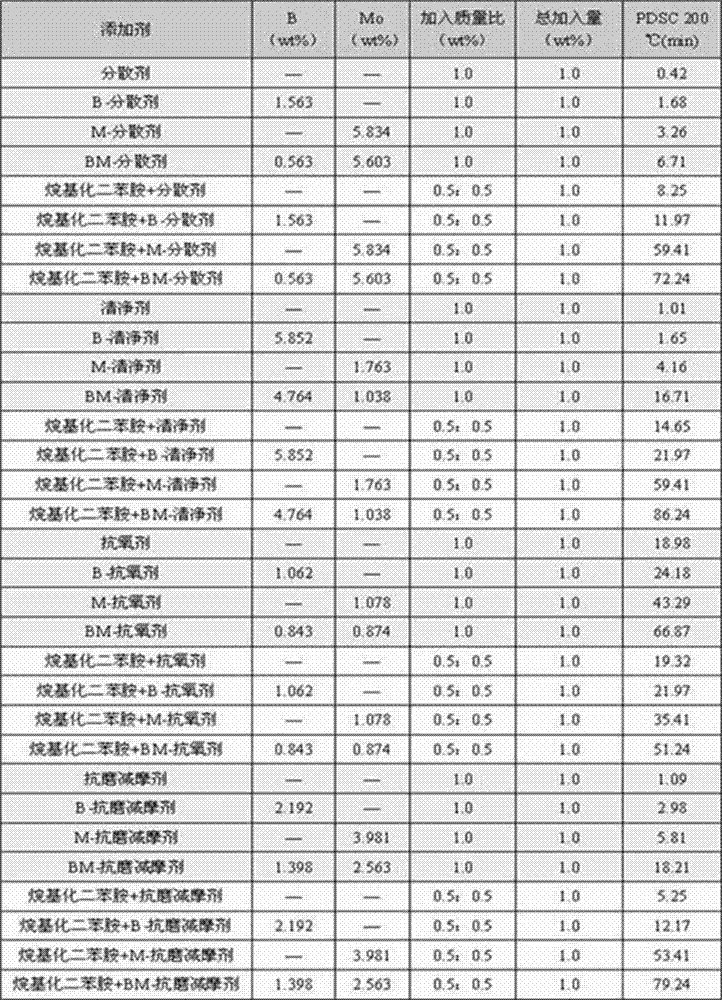

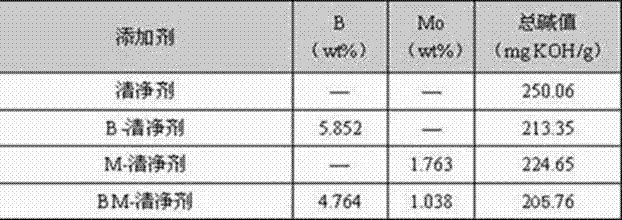

Examples

Embodiment Construction

[0064] As mentioned above, in view of many deficiencies in the prior art, the inventor of this case has been able to propose the technical solution of the present invention after long-term and in-depth research and extensive practice, as detailed below.

[0065] The invention provides a lubricating oil additive integrated with boron and molybdenum. The additive not only has good oil solubility, but also has excellent anti-wear, anti-friction and synergistic anti-oxidation properties.

[0066] In order to achieve the above object, the technical scheme adopted in the present invention comprises:

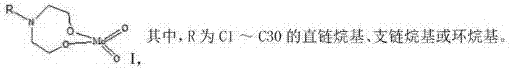

[0067] A boron-molybdenum integrated lubricating oil additive, the additive is a macromolecular and / or organic-inorganic hybrid structure additive, and inorganic boron atoms and molybdenum atoms are simultaneously introduced into the additive structure.

[0068] Wherein, the boron atom used to introduce the oil-soluble additive of the present invention is derived from a boron-containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com