Horizontal box type maintainable exhaust gas after-treatment device for ship engine

A marine engine and exhaust after-treatment technology, applied in exhaust treatment, exhaust devices, engine components, etc., can solve the problems of inability to clean and maintain and replace catalysts, great use and replacement costs, and high risk of urea crystallization. To achieve the effect of convenient regular maintenance and inspection, meet regular maintenance, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

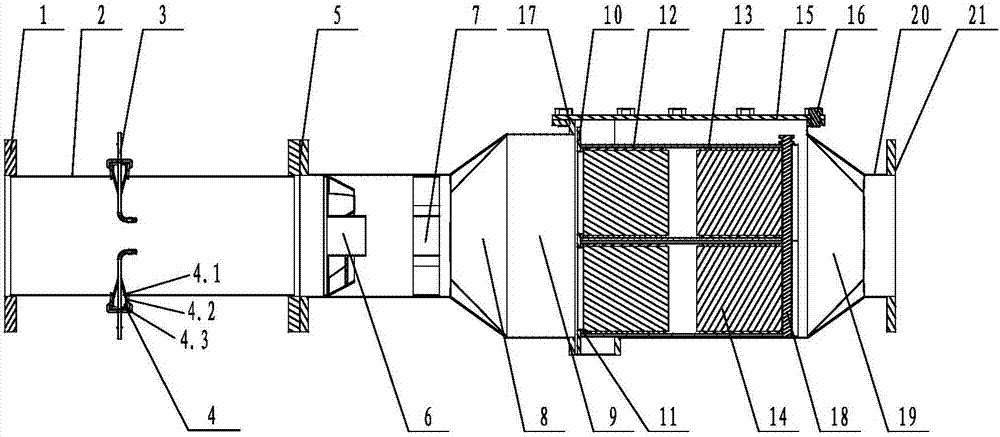

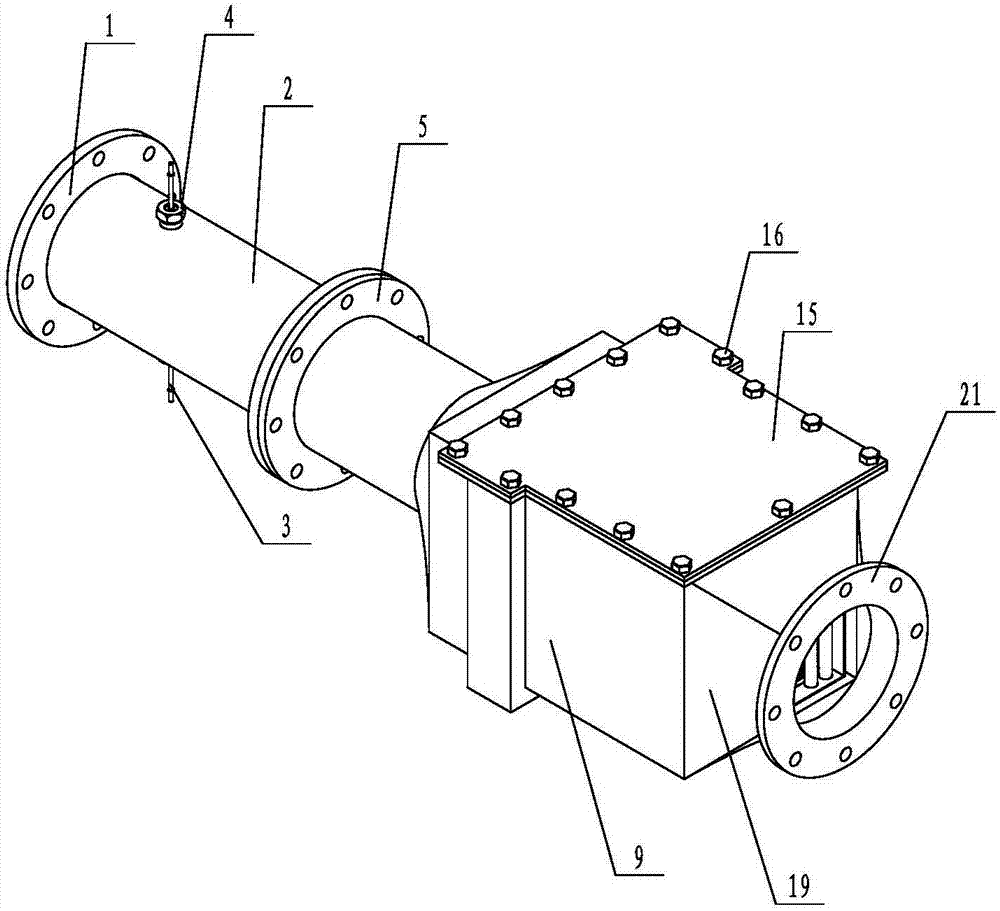

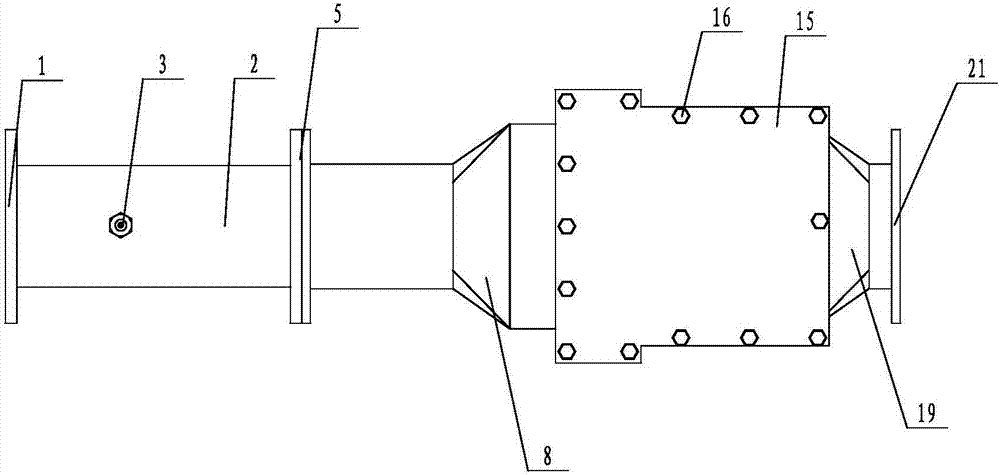

[0029] The present invention will be further described below in conjunction with the embodiment according to the drawings and the accompanying drawings.

[0030] Such as Figure 1-4 As shown, a marine engine horizontal box-type maintainable exhaust after-treatment device includes an intake pipe 2 , a urea nozzle 3 , a mixer, a case 9 , a catalytic assembly and an outlet pipe 20 . The intake end of the intake pipe 2 is provided with an intake flange 1, and the urea nozzle 3 is arranged on the intake pipe 2, and is fixed by a fixing device 4. The fixing device 4 includes a tapered sleeve 4.1, a mounting sleeve 4.2 and a screw sleeve 4.3, The tapered sleeve 4.1 is located inside the installation sleeve 4.2, and the screw sleeve 4.3 is set outside the installation sleeve 4.2. There are at least two urea nozzles 3, and in this embodiment, there are two urea nozzles 3, which are symmetrically arranged on the intake pipe 2, which effectively improves the working efficiency. The mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com