Condensate water recycling and conveying system and method thereof

A technology of condensate and delivery tanks, which is applied in steam/steam condensers, supplementary water supply, lighting and heating equipment, etc. It can solve the problems of inability to directly connect to condensate recovery, so as to prevent device stagnation and failure, reduce maintenance costs, Effect of improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

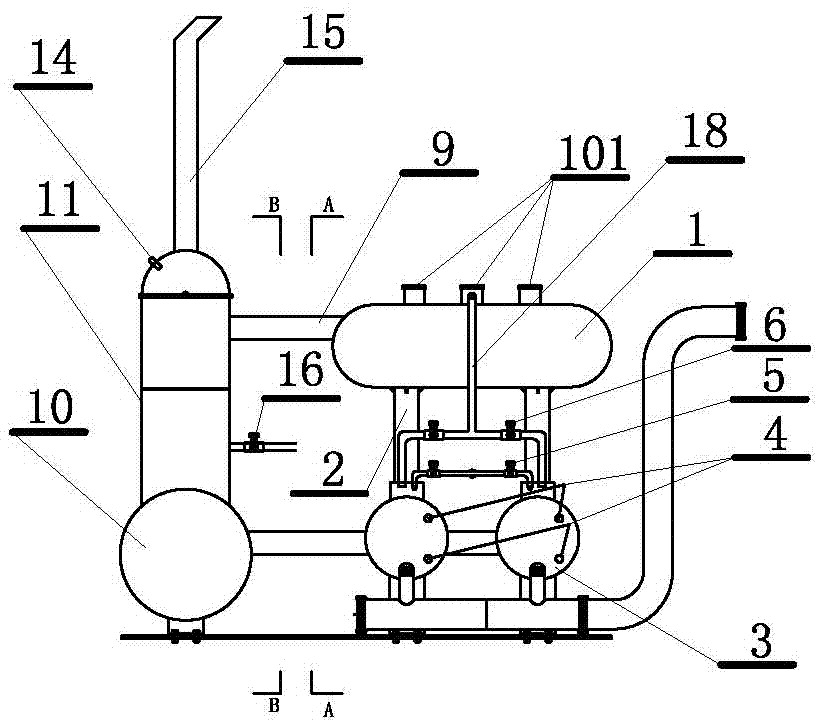

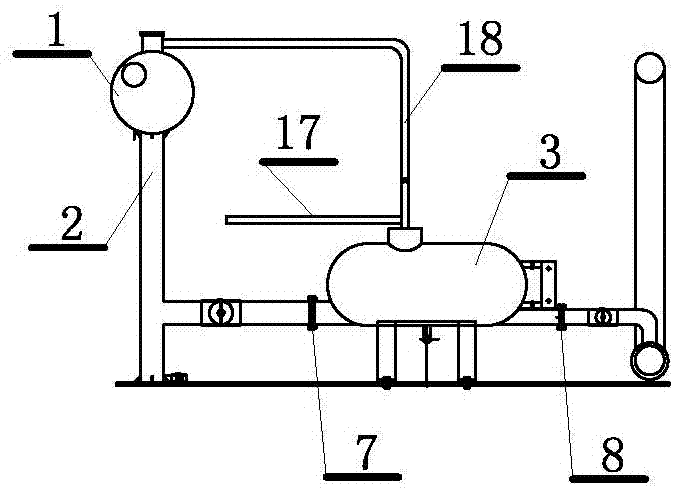

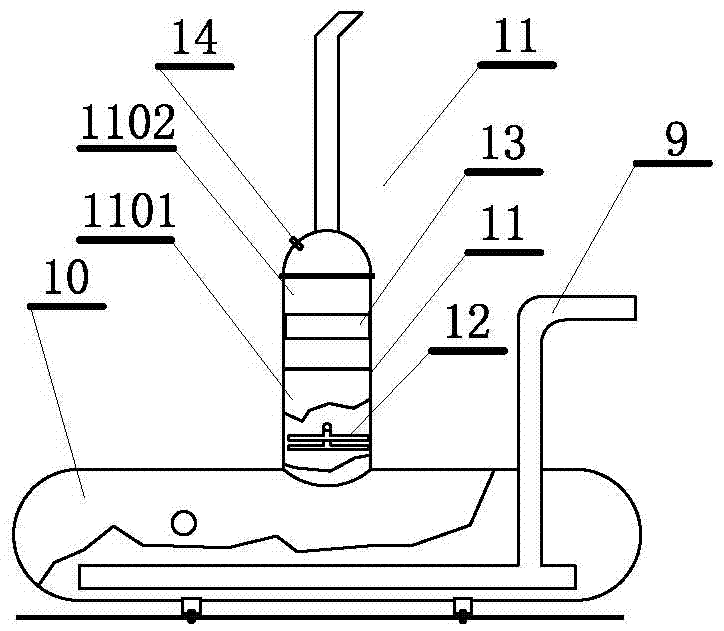

[0026] A condensate recovery delivery system such as figure 1 with figure 2As shown, the system includes a condensed water collection tank 1 connected to the main steam transmission pipeline or the high-temperature condensed water recovery pipeline through the connection port 101, and the bottom end of the water collection tank is connected to the condensate of the condensed water delivery tank 3 through the pipeline 2. There can be multiple water inlets and condensed water delivery tanks according to actual applications. The figure shows that two are provided in this embodiment, wherein a high and low liquid level double-contact electric contact liquid level gauge 4 is arranged in the condensed water delivery tank. , the upper end of the condensed water delivery tank is provided with a power gas source input port and a power gas discharge nozzle. Solenoid valve 6 discharges the power gas input in the condensate delivery tank, and the input power air presses the condensate i...

Embodiment 2

[0034] A method for collecting and discharging condensed water, more specifically, a method for collecting and discharging condensed water in a main steam transmission pipeline or a condensed water recovery pipeline; this embodiment is realized on the basis of Embodiment 1, therefore, the embodiment The content in 1 should be regarded as a supplement to this embodiment. The method is: connect a condensate water collection tank to the main steam transmission pipeline or high-temperature condensate recovery pipeline, and the bottom end of the water collection tank is connected to The condensed water inlet of the condensed water delivery tank is provided with a power gas source input port and a power gas discharge nozzle at the upper end of the condensate water transfer tank. The power gas source input port is connected to a power gas source through the first solenoid valve, and the power gas discharge pipe The power gas input in the condensed water delivery tank is discharged thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com