Quick automatic testing fixture for automotive connector

An automotive connector and automatic inspection technology, applied in electrical connection testing, instruments, measuring devices, etc., can solve problems such as unavoidable bumps and impacts, connector pin pin drop, connector maintenance or scrapping, etc., to reduce inspections. Error rate, less visual fatigue, and the effect of improving inspection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

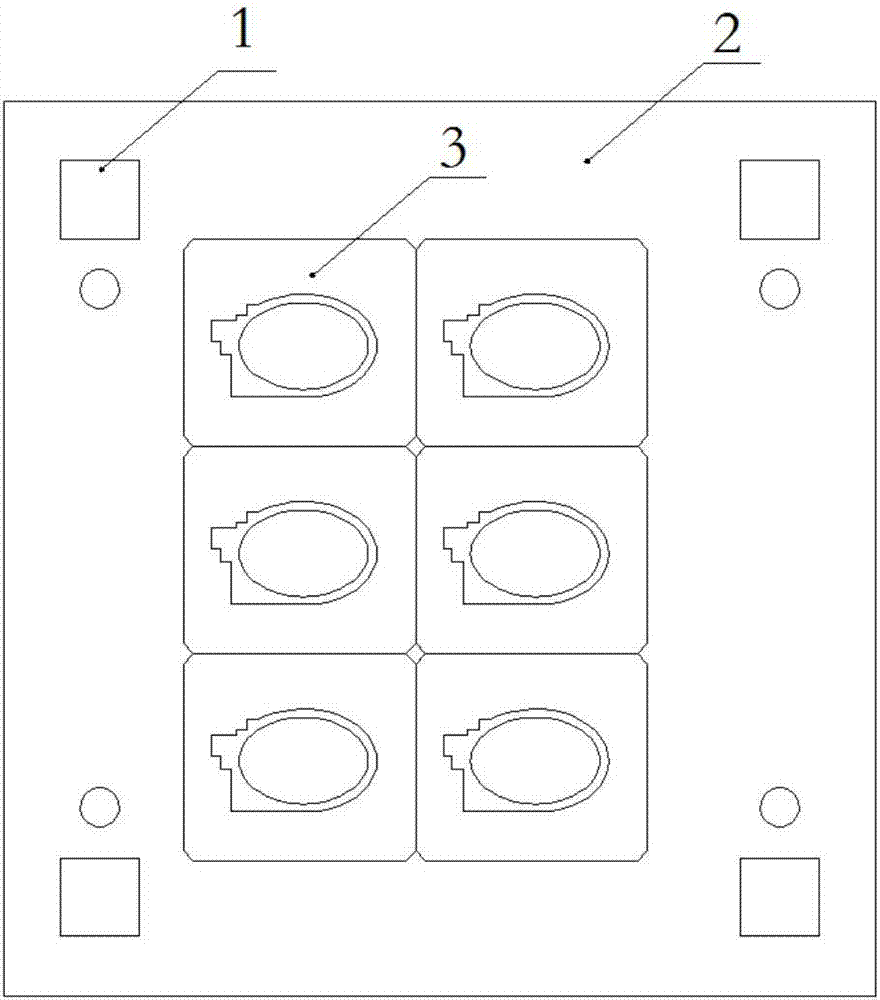

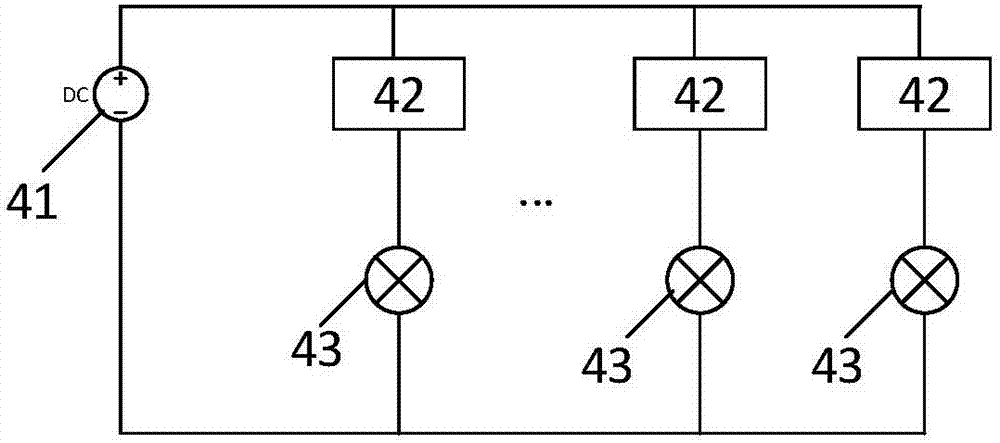

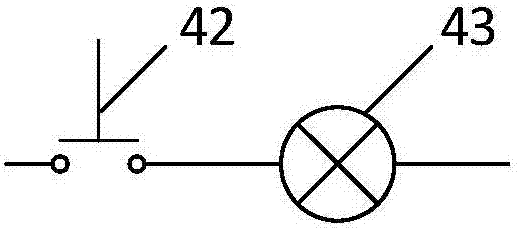

[0030] Such as figure 1 As shown, a kind of fast automatic inspection tool for automobile connector comprises a base plate 2, a PIN pin contact table 3 and a detection circuit, and the described PIN pin contact table 3 and the detection circuit are arranged on the base plate 2, and the detection circuit includes multiple A branch connected to the power supply 41, the power supply 41 adopts a 1.5-3.5V DC power supply, and the number of branches is the same as the number of PIN pins of the connector to be detected, such as figure 2 As shown, each branch is connected in parallel with each other, and each branch is provided with a pressure contact switch 42 and a status display lamp 43 connected in series. The pressure contact switch 42 is arranged on the PIN needle contact platform 3, and each pressure contact The position of the point switch 42 is in one-to-one correspondence with each PIN pin position of the connector to be detected.

[0031] Such as image 3 As shown, the p...

Embodiment 2

[0037] As a second case of pressure contact switch 42, as Figure 4 As shown, the contact of the pressure contact switch 42 is a normally closed contact, which is in a closed state in a natural state, and the corresponding state indicator light 43 lights up; when the pressure contact switch 42 is deformed by the pressure of the PIN needle, the corresponding The branch circuit is disconnected, and the corresponding state display lamp 43 is extinguished, indicating that the shape of the PIN needle is qualified.

[0038] The structure of the remaining parts of the inspection tool is the same as that of the PIN needle inspection operation method in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com