RFID-based automatic positioning method and apparatus

An automatic positioning and RFID tag technology, applied in the direction of collaborative operation of devices, instruments, computer parts, etc., to achieve the effect of high intelligence, strong practicability, and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides an automatic positioning method and device for a garbage crane in a workshop of a garbage incineration power plant.

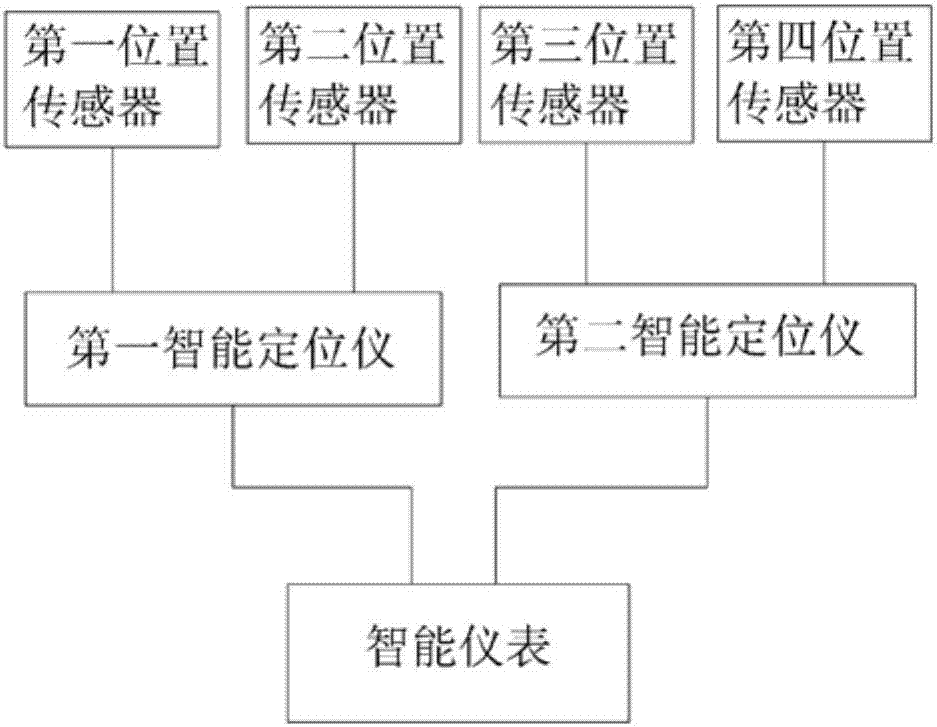

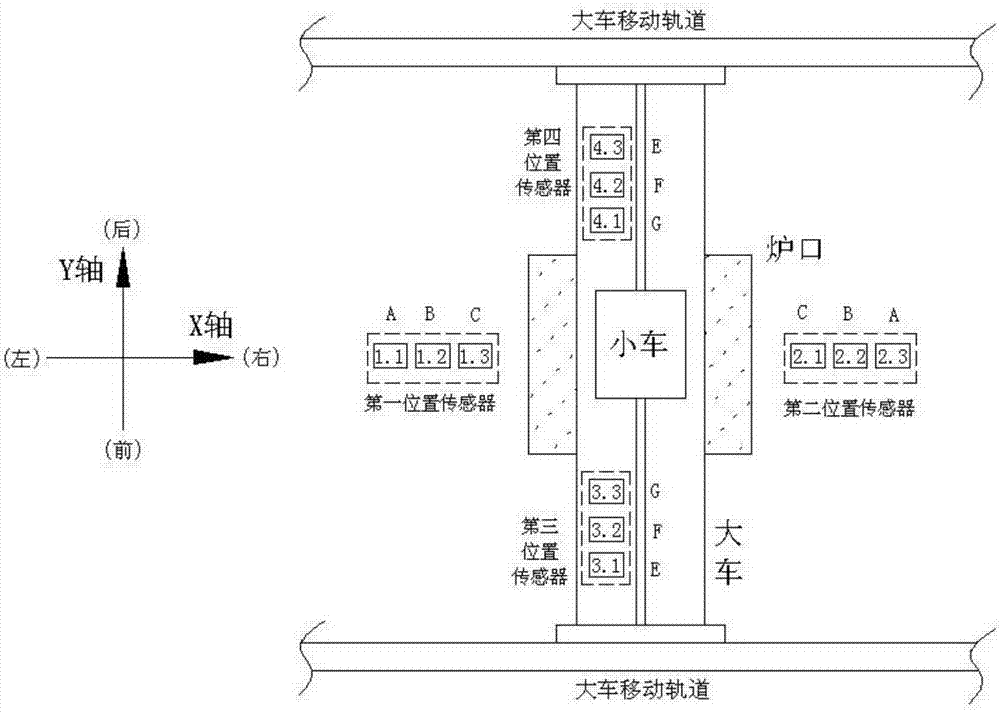

[0041] Such as figure 1 and figure 2 As shown, the automatic positioning device includes a first position sensor, a second position sensor, a first intelligent positioner connected to the first position sensor and the second position sensor, a third position sensor, a fourth position sensor, respectively The second intelligent locator connected with the third position sensor and the fourth position sensor and the smart meter connected with the first intelligent locator and the second intelligent locator respectively, the first position sensor is located at figure 2 On the left side of the furnace mouth shown in , the second position sensor is arranged on the right side of the furnace mouth, wherein the furnace mouth is used for garbage hoisting to feed materials therein, and the fire mouth is the positioning point (or claiming...

Embodiment 2

[0066]As another preference, this embodiment provides another automatic positioning method and device for a garbage crane in a workshop of a waste incineration power plant. Its system configuration and working mechanism are basically the same as those in Embodiment 1, except that the installation positions of the second intelligent locator, the third position sensor and the fourth position sensor in Embodiment 2 are different from those in Embodiment 1, specifically: the first The three position sensors and the fourth position sensor are all installed on the trolley of the garbage crane, and the second intelligent locator is installed on the cart of the garbage crane. As for its working principle, it is the same as that of the first embodiment, and will not be repeated here.

[0067] Compared with embodiment 1, the advantage of embodiment 2 is: the second intelligent locator does not need a slip line.

Embodiment 3

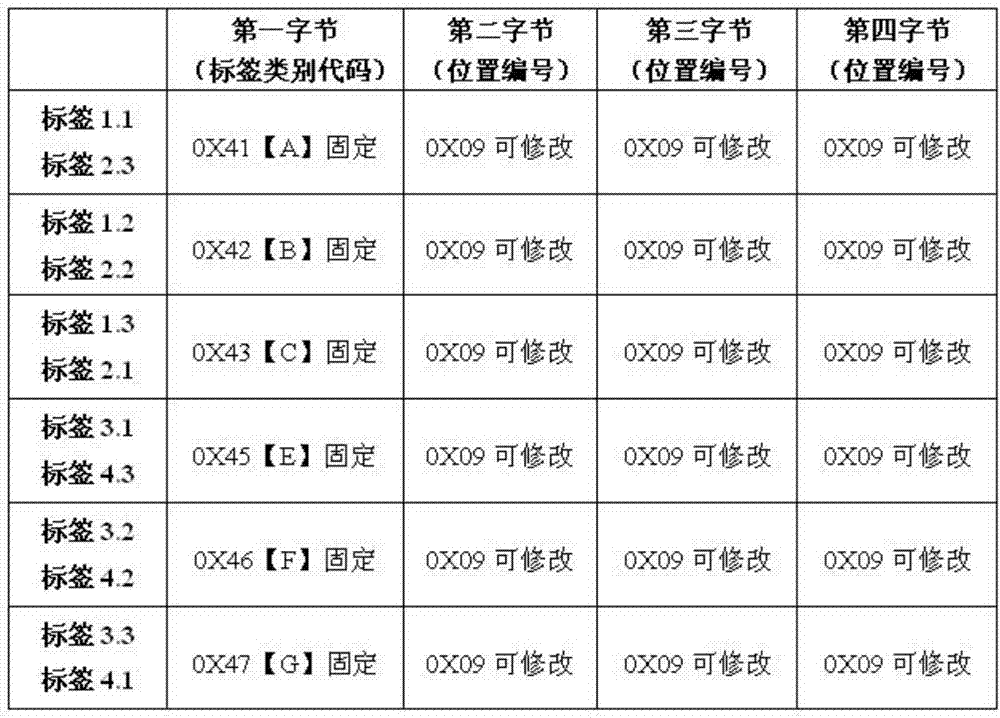

[0069] As another embodiment, the difference between embodiment 3 and embodiment 1 is that in this embodiment, the first position sensor, the second position sensor, the third position sensor and the fourth position sensor each include 2 RFID tags arranged equidistantly (specifically, as respectively removing the tag 1.3 of the first position sensor, the tag 2.1 of the second position sensor, the tag 3.3 of the third position sensor and the fourth position sensor 4.1, while retaining the remaining tags ). In this way, the same as the specific working process described in Embodiment 1, in the moving process of the cart, no matter whether the cart moves into the furnace mouth area from the left or the right of the furnace mouth, the first intelligent locator will use a certain Sequentially perceive the two RFID tags in the first position sensor or the second position sensor; and when the cart is already in the furnace mouth area, no matter whether the cart moves out of the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com