Air battery equipped with rotary bearded zinc electrodes and star-like air electrodes

An air electrode and air battery technology, applied in the field of battery processing and manufacturing, rotating whisker-shaped zinc electrode star-shaped air electrode air battery, can solve the problem that the replacement method cannot meet the power supply for vehicles, reduce the utilization rate of raw materials, and is unfavorable for commercial operation, etc. The problem is to overcome the decline in battery performance, the production method is economical, and it is easy to achieve large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

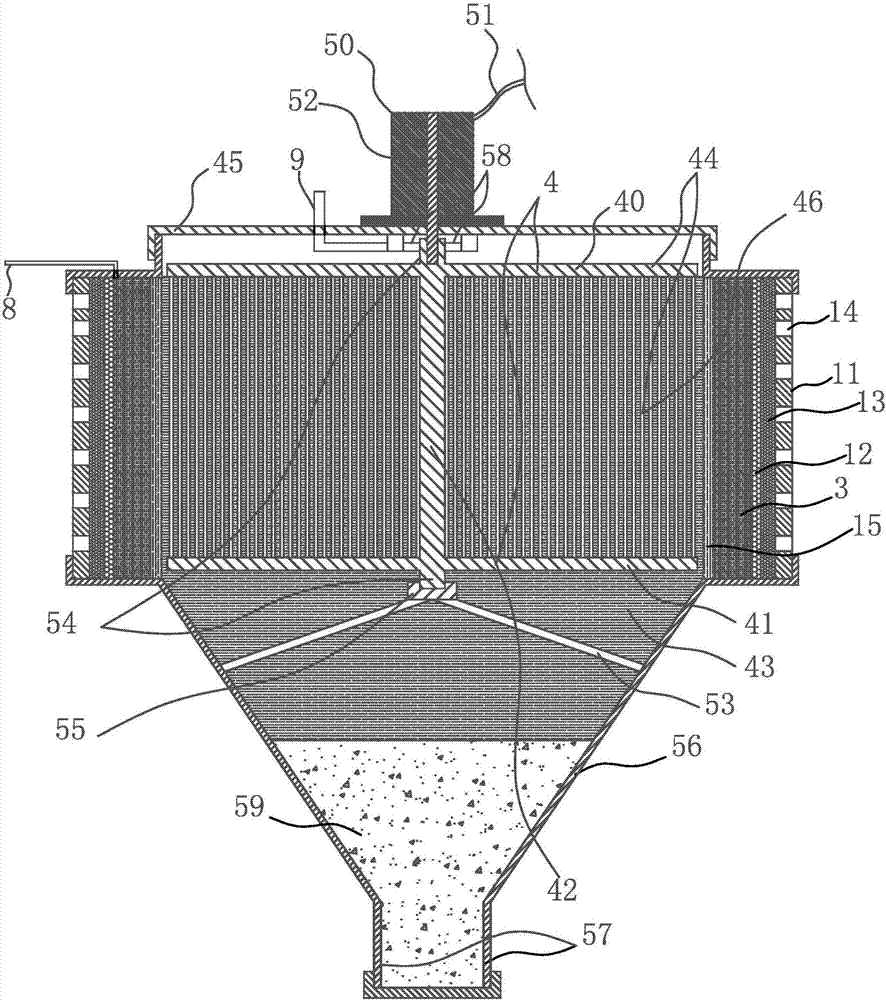

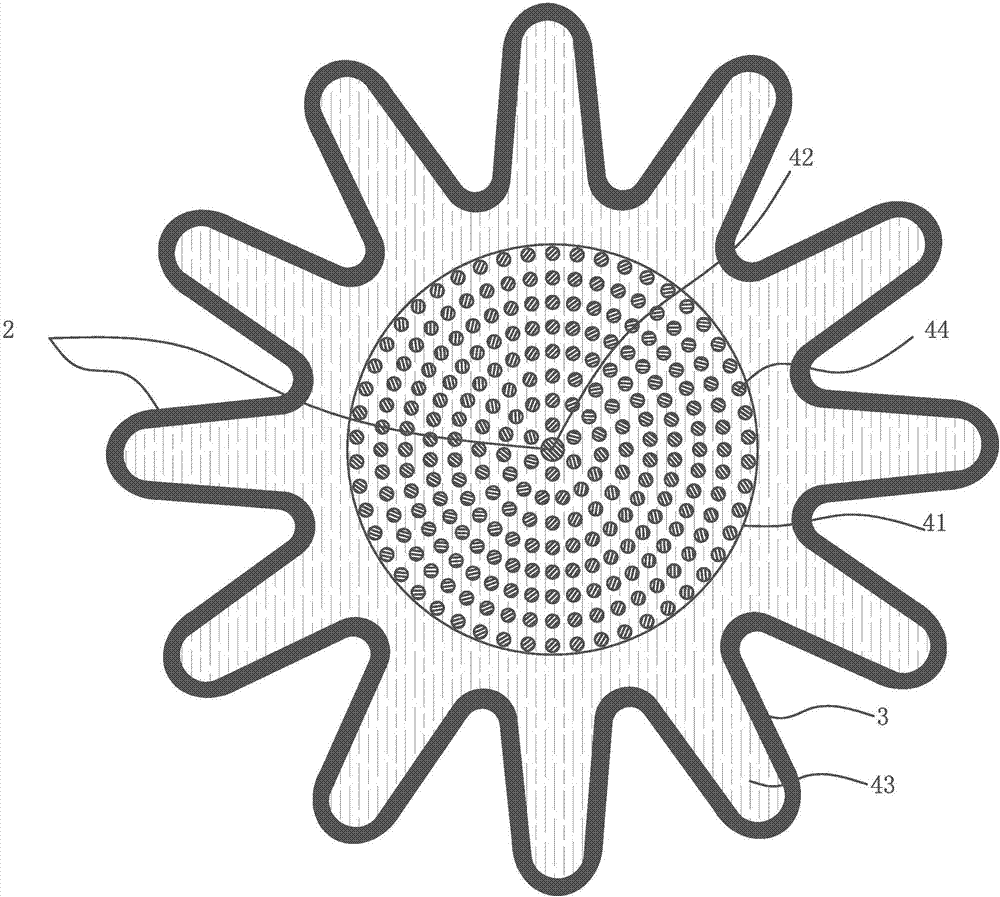

[0012] Such as Figure 1-2 As shown, a rotating whisker-shaped zinc electrode star-shaped air electrode air battery includes a battery reaction tank (2), an air electrode lead wire (8), and a zinc electrode lead wire (9). It is characterized in that: the battery reaction tank (2) ) is an open mouth, and is provided with a movable reaction tank cover (45); the side of the battery reaction tank (2) is surrounded by air electrodes (3) into a star shape (the purpose of surrounding the air electrodes into a star shape is to increase the air electrode area), the bottom of the battery reaction tank (2) is provided with a cone (56), and the lower end of the cone (56) is provided with a zinc oxide discharge port (57); the battery reaction tank (2) is filled with electrolyte (43 ), and a zinc electrode (44) is provided.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com