Structure engineering construction equipment for municipal wastewater treatment

A technology for engineering construction and municipal sewage, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of sand easily entering the eyes of workers, high labor intensity, and low screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

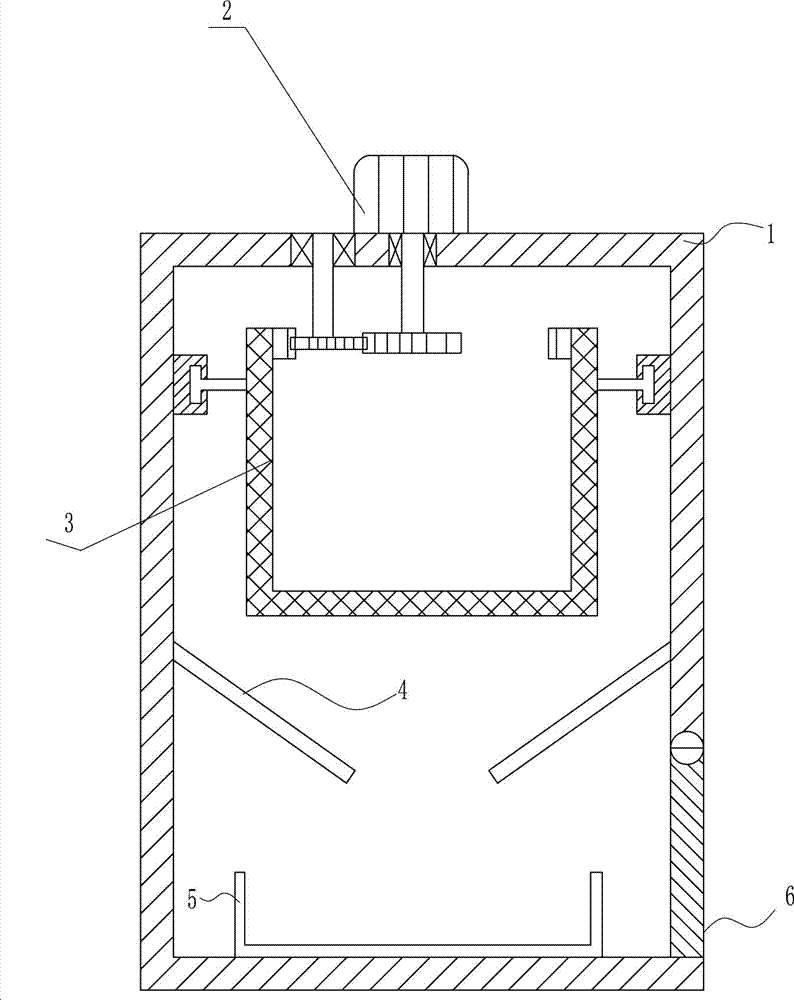

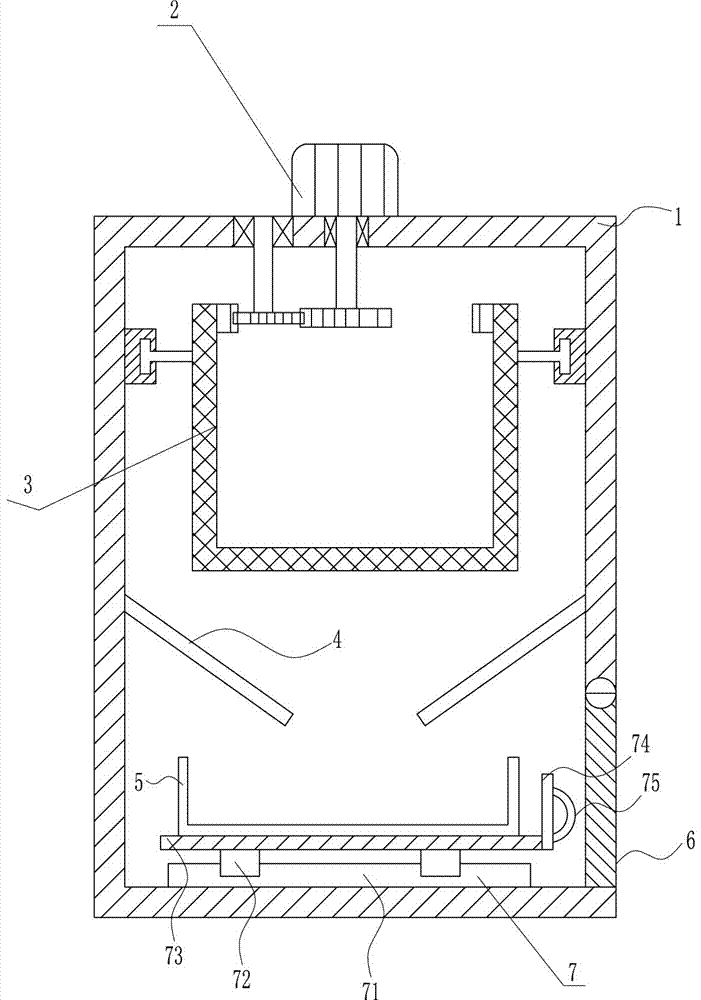

[0029] A structure engineering construction equipment for municipal sewage treatment, such as Figure 1-4 As shown, it includes a box body 1, a driving device 2, a screening device 3, a hopper 4, a collection frame 5 and a baffle plate 6, the top of the box body 1 is provided with a driving device 2, and the inner upper part of the box body 1 is provided with a screening device 3. The middle part of the box body 1 is connected with the hopper 4 through bolt connection, the hopper 4 is located below the screening device 3, the collection frame 5 is placed at the bottom of the box body 1, and the lower right side of the box body 1 is connected by a pin shaft Baffle plate 6 is arranged, and baffle plate 6 cooperates with box body 1.

Embodiment 2

[0031] A structure engineering construction equipment for municipal sewage treatment, such as Figure 1-4 As shown, it includes a box body 1, a driving device 2, a screening device 3, a hopper 4, a collection frame 5 and a baffle plate 6, the top of the box body 1 is provided with a driving device 2, and the inner upper part of the box body 1 is provided with a screening device 3. The middle part of the box body 1 is connected with the hopper 4 through bolt connection, the hopper 4 is located below the screening device 3, the collection frame 5 is placed at the bottom of the box body 1, and the lower right side of the box body 1 is connected by a pin shaft Baffle plate 6 is arranged, and baffle plate 6 cooperates with box body 1.

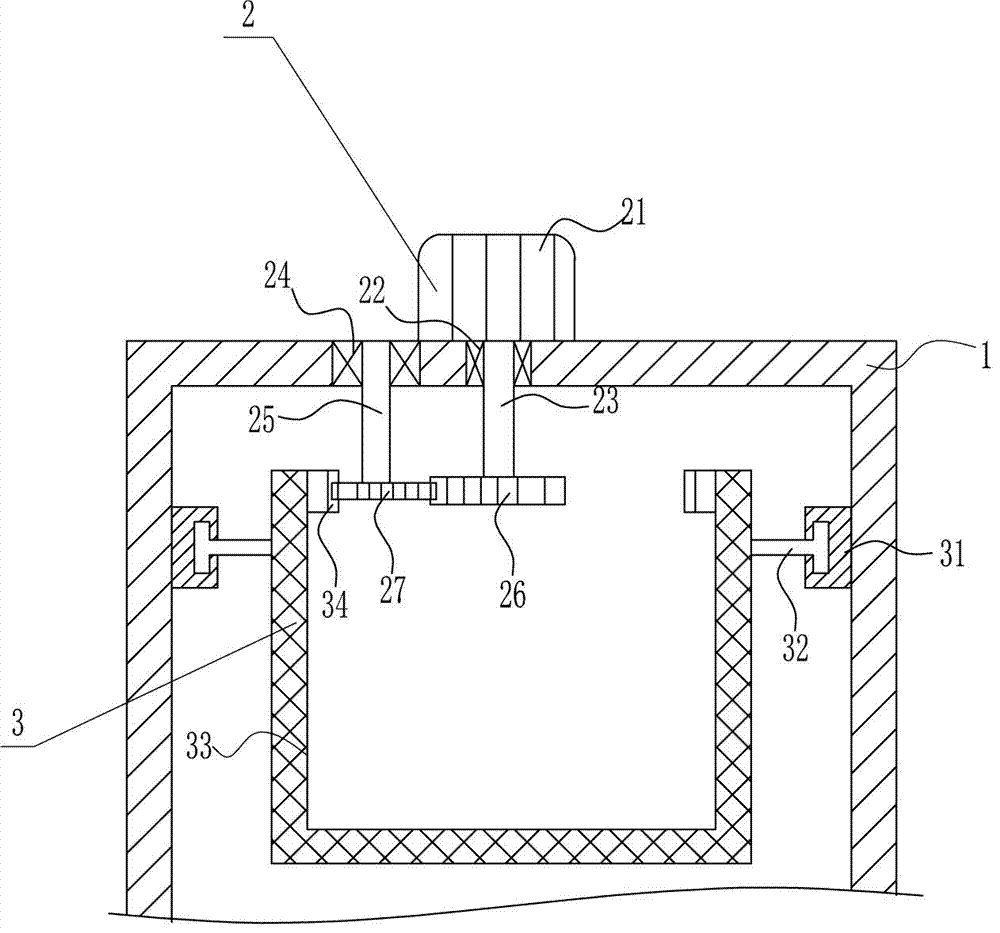

[0032]The driving device 2 includes a driving motor 21, a first bearing seat 22, a first rotating shaft 23, a second bearing seat 24, a second rotating shaft 25, a first gear 26 and a second gear 27, and the top of the box body 1 is connected by bol...

Embodiment 3

[0034] A structure engineering construction equipment for municipal sewage treatment, such as Figure 1-4 As shown, it includes a box body 1, a driving device 2, a screening device 3, a hopper 4, a collection frame 5 and a baffle plate 6, the top of the box body 1 is provided with a driving device 2, and the inner upper part of the box body 1 is provided with a screening device 3. The middle part of the box body 1 is connected with the hopper 4 through bolt connection, the hopper 4 is located below the screening device 3, the collection frame 5 is placed at the bottom of the box body 1, and the lower right side of the box body 1 is connected by a pin shaft Baffle plate 6 is arranged, and baffle plate 6 cooperates with box body 1.

[0035] The driving device 2 includes a driving motor 21, a first bearing seat 22, a first rotating shaft 23, a second bearing seat 24, a second rotating shaft 25, a first gear 26 and a second gear 27, and the top of the box body 1 is connected by bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com