Lathe spindle safety protection device and use method thereof

A safety protection device, a technology of a lathe spindle, applied in the field of machinery, can solve the problems of inability to achieve humanized control effects, easy influence of signal feedback, inability to apply chuck wrenches, etc., and achieves simple structure, good versatility and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

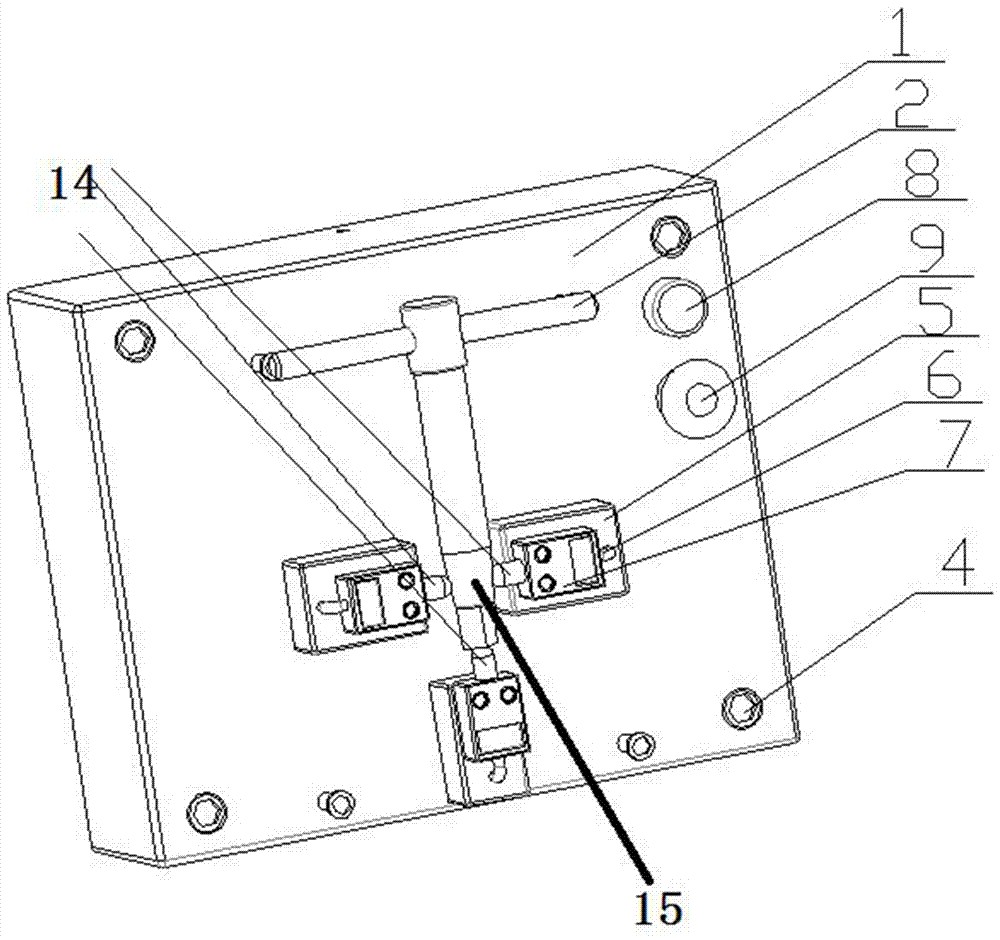

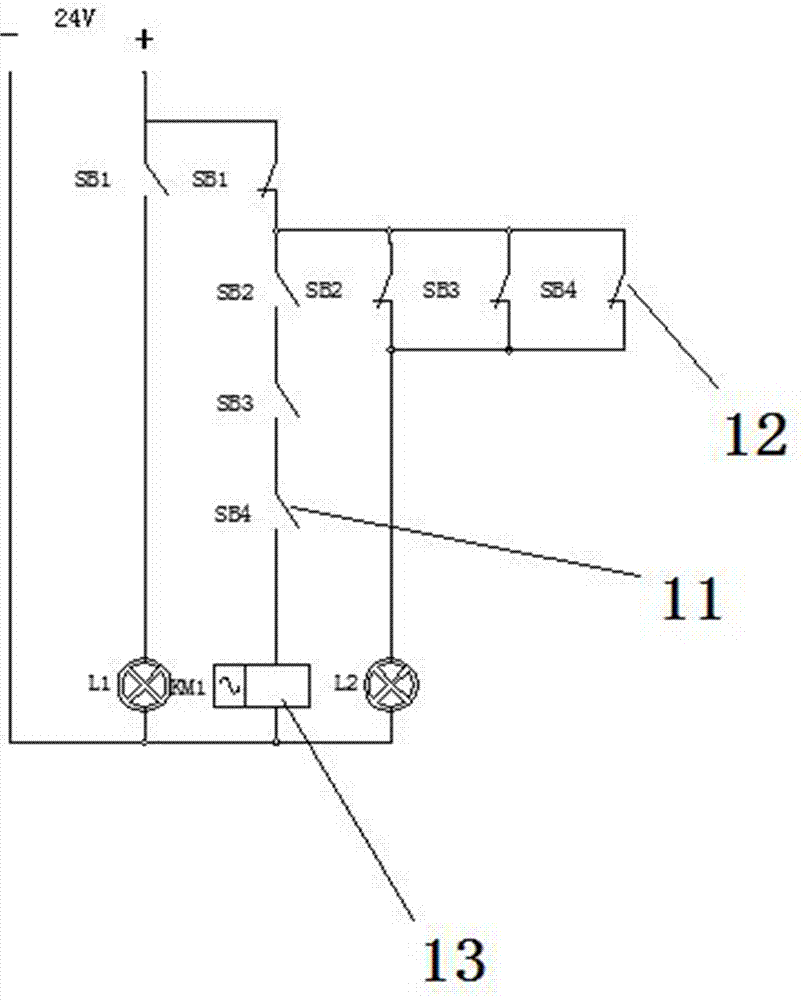

[0043] A travel switch fixing block 5 is used to fix three travel switches 7 at the wrench fixing seat of the lathe casing, and each travel switch 7 is connected by a wire 6; a safety circuit and a machine tool drive circuit connected by the wire 6 are arranged inside the casing, and the safety circuit is provided with There are emergency switch 9 and indicator light 8. When the safety circuit senses that the wrench is not correctly placed in the wrench storage area, if the machine tool motor drive circuit is restarted, an alarm will be issued.

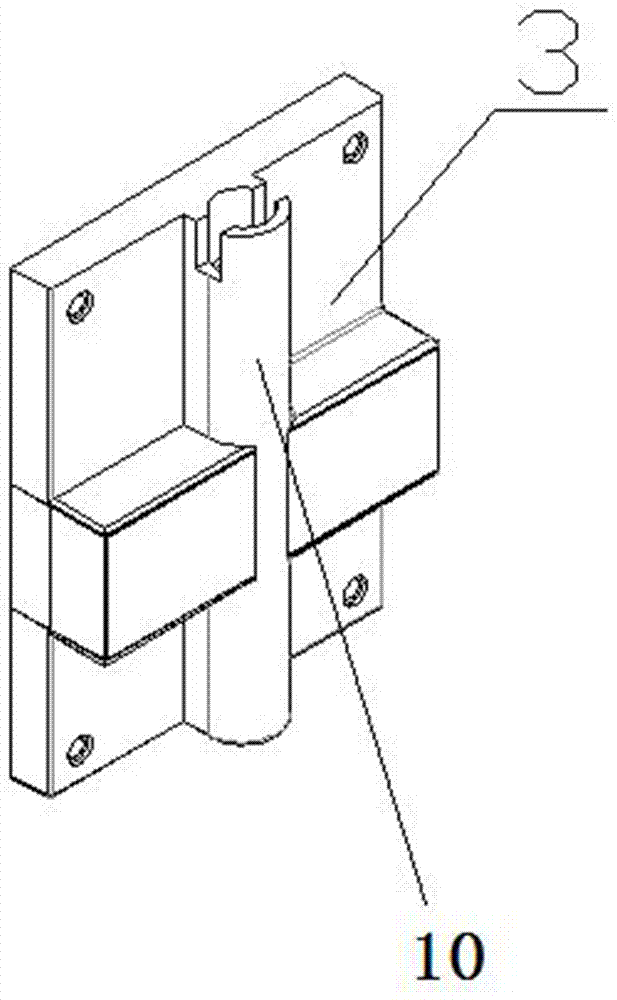

[0044] When the chuck wrench 2 is inserted into the wrench holder 3, the two travel switches on the left and right sides are in contact with one travel switch at the bottom, and the three travel switch contacts SB2, SB3, and SB4 are closed, and the machine tool drive circuit Point contact, the indicator light 8 is green, the machine tool can work normally, when the chuck wrench 2 is not inserted into the wrench holder 3, the three trav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com